8

MHCP Primary Cleaner

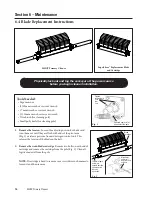

Section 4 – Installation Instructions

Physically lock out and tag the conveyor at the power source

before you begin cleaner installation.

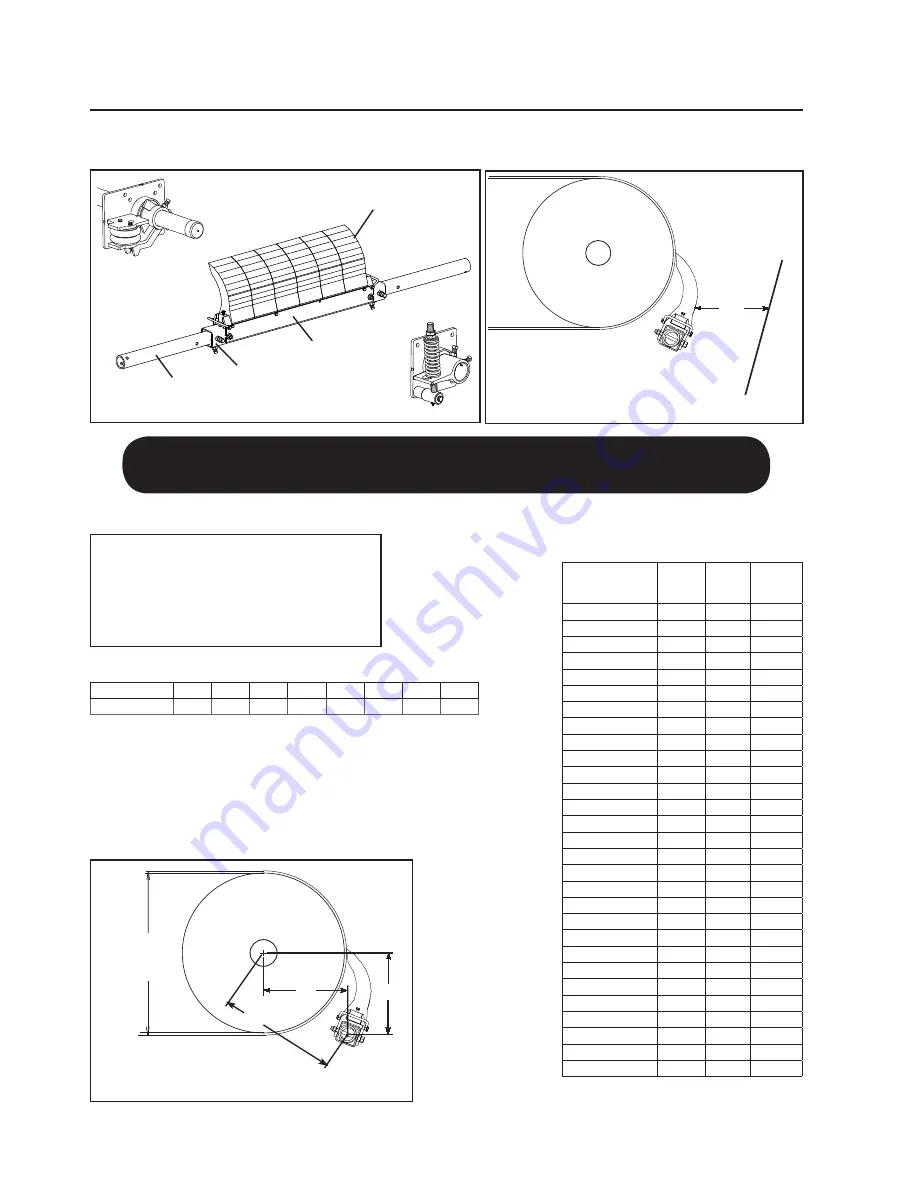

1. Find the X, Y & C specifications. Measure the pulley diameter

(including the belt and the lagging) (Fig. 1).

Pulley Diameter _____

mm

; X=_____

mm

; Y=_____

mm

; C=_____

mm

.

(Adjustments can be made to the X & Y coordinates to move away

from obstacles as long as the C dimension remains constant.)

CAUTION: Components may be heavy. Use safety-approved lifting procedures.

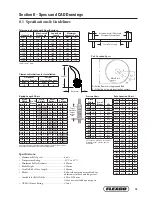

X & Y Chart for Pole Location

Pulley Diameter

(including belt

and lagging)

X

Y

C

500

254

365

445

525

267

365

451

550

279

365

460

575

292

365

467

600

305

365

476

625

318

365

483

650

330

365

492

675

343

365

502

700

356

365

511

725

368

365

518

750

381

365

527

775

394

365

537

800

406

365

546

825

419

365

556

850

432

365

565

875

445

365

575

900

457

365

584

925

470

365

594

950

483

365

606

975

495

365

616

1000

508

365

625

1025

521

365

635

1050

533

365

648

1075

546

365

657

1100

565

365

673

1125

581

365

686

1150

597

365

699

1175

610

365

711

1200

625

365

724

Blades per Cleaner Size

mm

600

750

900

1050

1200

1350

1500

1800

Blades Required

3

4

5

6

7

8

9

11

4.1 MHCP Primary Cleaner

Tools Needed:

• Tape Measure

• Wrenches or Crescent Wrenches: (2)19mm,

(2) 38mm, (1) 24mm, and (1) 16mm

• C-clamps for AWT only

Fig. 1

X

C

Y

Pole Location Specs

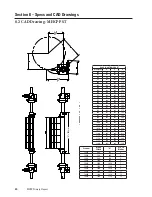

Pulley Diameter

(incl. belt and

lagging)

AWT Air/Water Tensioner

PST Spring Tensioner

Supershear Blades

Blade Cartridge

Centre Pole

Extender Pole

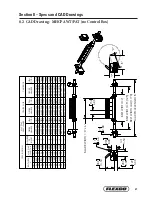

MHCP Parts List

Chute Wall

Recommended spacing from back chute wall

Maximum

lump size

+ 200mm (8")