9

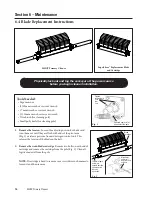

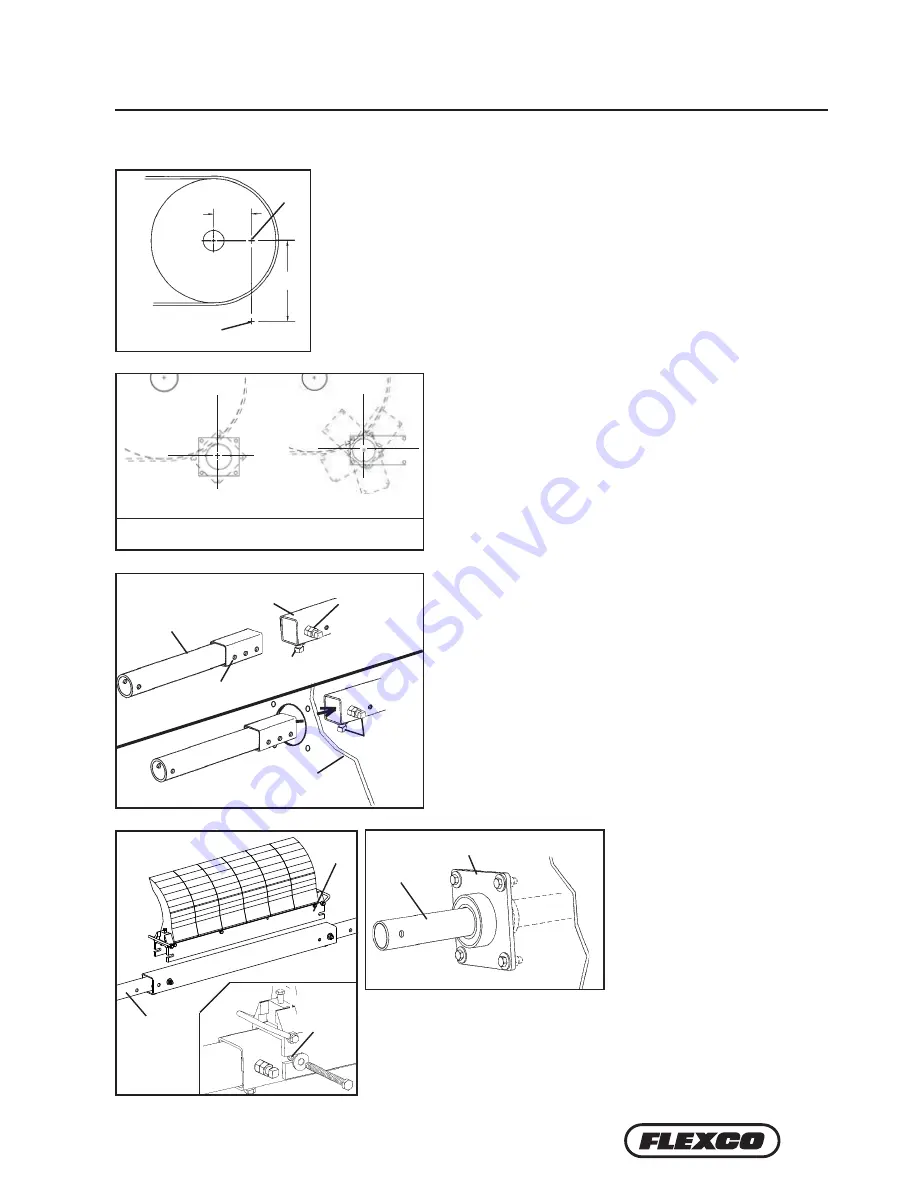

5. Install the mounting bases.

Bolt the mounting bases to the

chute with the bolts provided

(Fig. 5).

6. Install the blade cartridge.

Place the blade cartridge onto

the centre pole. Adjust the

extender poles until the holes

align with the holes in

the centre pole and lock the cartridge into place with the two bolts,

washers and nuts (Fig. 6). NOTE: Be sure at least 150mm of the extender

pole extends out of the mounting base on each side for tensioner

installation. Adjust the extender poles in the centre pole if more or less

length is needed.

Section 4 – Installation Instructions

2. Lay out the dimensions on the chute wall. Measure out the X dimension

horizontally from the centre of the pulley shaft and mark. (NOTE: It may be

easier to put a level on top of the pulley shaft, draw a horizontal line and then

measure down half the diameter of the shaft and make a line from the front of

the shaft. Now subtract half the pulley shaft diameter from the X coordinate

and measure on the line and make a mark.) Then measure down vertically the

Y dimension and mark. This is the correct position for the centre of the cleaner

pole (Fig. 2). Lay out and mark the same dimensions on the other side.

3. Mark and cut the mounting base holes. Using the

mounting base template provided in the instruction packet,

position the large pole hole of the template on the chute with

the hole notches aligned with the layout lines. Trace the pole

hole and mounting holes (Fig. 3). Each base can be mounted

in any position 360° around the pole as long as the pole’s

centre point does not change. Cut the holes on both sides of

the chute.

4. Assemble the extender poles to the centre pole. Insert the

extender poles through the chute holes and into the centre

pole and make sure the locating bolt holes align with the

centre pole holes (holes are offset to the lower half). Position

the centre pole with the welded nuts and locking bolts on

one side facing down and on the adjoining side facing away

from the head pulley (Fig. 4). Leave the locking bolts loose.

4. 1 MHCP Primary Cleaner (cont.)

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting base

Template for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 2

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting base

Template for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 3

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting base

Template for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 4

mark

Y

X

mark

Center large template hole notches on pole center mark,

rotate to desired angle and trace holes

Template for

PST mounting base

Template for

AWT/NT mounting base

Blade

Cartridge

6" of pole end

must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts

Extender

Pole

Mounting Plate

(Pst Shown)

Chute wall

(cut away)

Chute wall

(cut away)

Center Pole

Extender Pole

Must be facing

away from

head pulley

Locating bolt

holes

Locking

Bolts

Must align with

extender pole

holes

Must be

facing down

Fig. 5

Fig. 6

Blade

Cartridge

150 mm of pole

end must extend

outside the

mounting base

on each side

Align holes

and install

bolts, washers

and nuts