10

Instructions

Installing Flexco

®

SR

™

Fasteners with the Flexco

®

Power Set

™

Rivet Driver

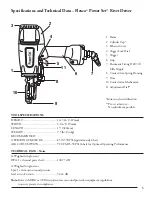

1. Square belt using centerline

method. Cut belt 2-3” (50-75 mm)

behind old splice using Flexco

®

840

Series Belt Cutter. Skive belt when

top cover permits.

2. Measure belt thickness from cut

edge using gauge or tape measure.

Select correct size Power Set Rapid

Loader

™

collated rivets with washers

for your belt thickness. When skiving,

measure the belt thickness after a

portion of the belt cover has been

removed.

3. Place tool on wooden board the

width of the conveyor framework for

support when using the MSRT or

MSRT8 tool. Adjust gauge pin guide

to the correct fastener size.

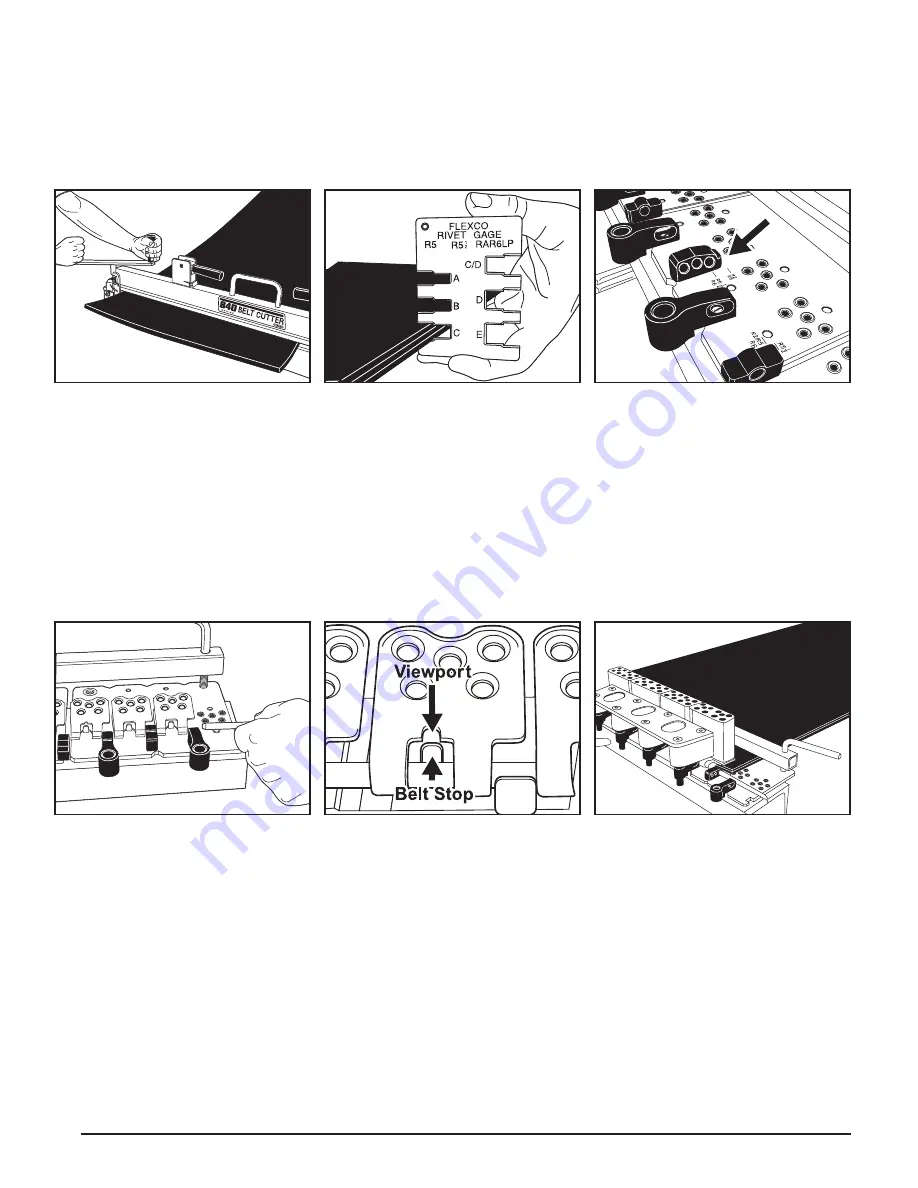

4. Center fastener strip on tool,

Flexco stamp facing up. The holes in

the fasteners and anvil plate must line

up. Insert gauge pin through guides

and fastener loops.

5. Center belt in fastener strip. Look

through viewports; belt ends should

be tight against belt stops. Tighten

hold down bar to secure belt.

6. Set all fastener top plates with

hammer blows. Place metal guide

block(s) at either end of the fastener

strip. Use the metal guide blocks

designed for use with the Power Set

™

Rivet Driver. Reduce installation time

by adding guide blocks across the

tool.

Summary of Contents for PSRD-1

Page 15: ...15...