8

U-Type

®

Secondary Cleaner

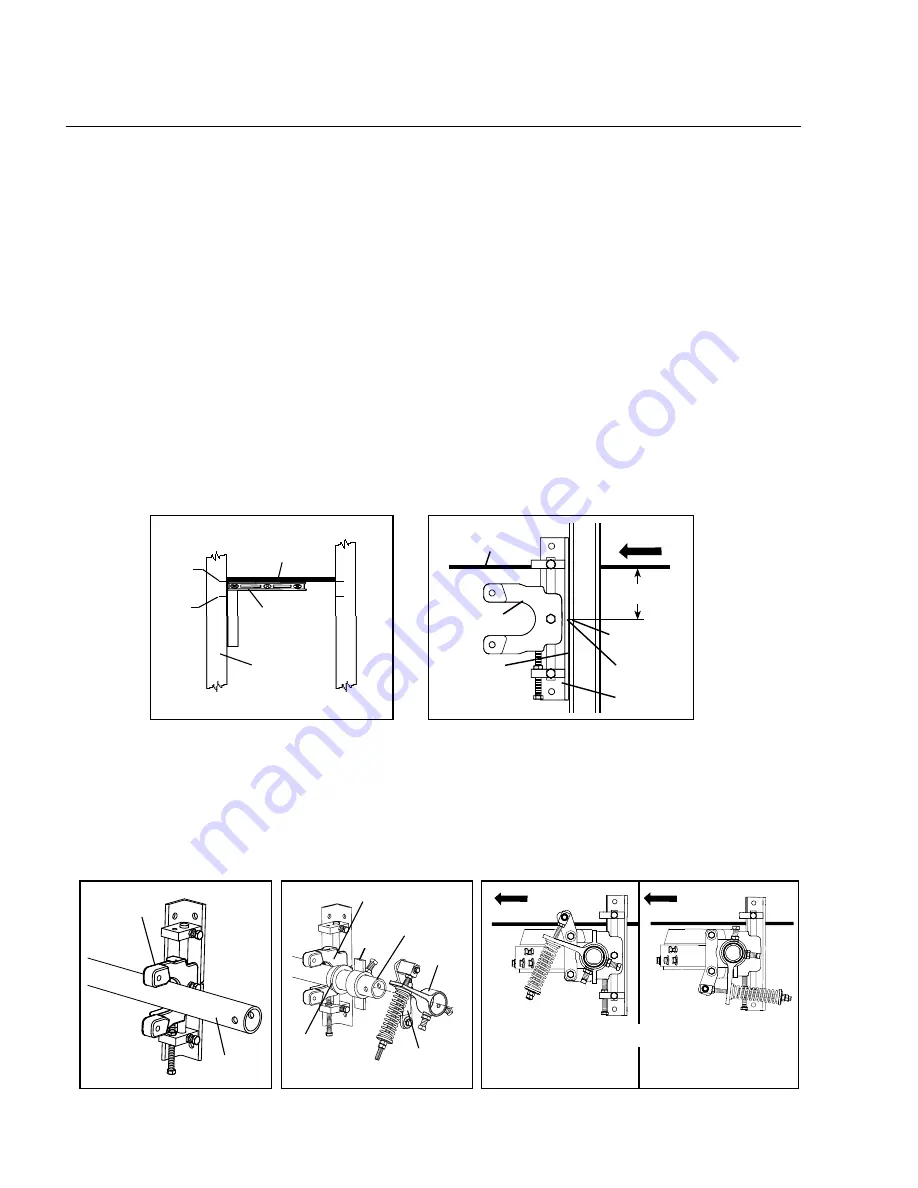

3U. Install the cleaner pole into the slider plates.

a. Set pole ends into slider plate on both sides (Fig. 3Ua).

b. Slide pole bearings onto both ends of the pole with flange facing away from the belt (Fig. 3Ub).

c. Slide stop collar onto both ends of the pole (Fig. 3Ub). Do not tighten at this time.

d. Slide torque arms onto both ends of pole and attach both pivot shaft brackets to slider plates (Fig. 3Ub).

Blade and torque arm must face either in the direction of belt travel (Fig. 3Uc), or if clearance is an issue,

switch to rotated tensioner configuration and assemble as shown (Fig. 3Ud).

e. Move slider plate to bottom of bracket to allow blade to rotate up into position in the next steps.

Fig. 3Ua

Repeat at

other end

Repeat at

other end

Slider Plate

Pole

Pole Bearing

(flange facing out)

Pole

- OR -

Fig. 3Ub

Slider Plate

Torque

Arm

Stop

Collar

Pivot Shaft

Bracket

Belt Direction

Belt Direction

Blade and torque arm

must face in the direction

of belt travel

If clearance is an issue

switch to rotated tensioner

configuration and assemble

as shown.

Section 4 - Installation Instructions

4.1 U-Type® Secondary Cleaner

Fig. 3Ud

Fig. 3Uc

Fig. 2Ua

2U. Install mounting brackets.

a. Using a level, lightly raise return side belt (take out cupping or sagging on edges) to find belt's true parallel path to

the structure; and mark reference point #1 on structure. Measure down 75mm (3”) from reference point #1 and

mark reference point #2 (Fig. 2Ua). Make sure brackets are the same distance away from head pulley or a reference

point on both sides of the structure. If there is no structure to mount to, install mounting bracket kit first.

b. Position mounting brackets so centerline marks on brackets are in line with reference points #2 on the structure

(Fig. 2Ub).

c. Clamp or weld into position.

Return

Side Belt

Belt Direction

Mounting

Bracket

Ref.

Point #1

Level

Return

Side Belt

Structure

Right

Side

Left

Side

#1

#2

Ref.

Point #2

Ref.

Point #2

Fig. 2Ub

Centerline on

Bracket

Bracket flush

to structure or

mounting kit

Slider Plate

3"

(75mm)

UST Tensioner Instructions

1. Choose conveyor location where cleaner will be installed.

The U-Type may be positioned at any spot from where belt leaves head pulley on down the conveyor line (see

positions A to B). If a chute area is too small due to a snub pulley, it may be necessary to mount cleaner behind

chute (see position C). In chute applications a minimum of 150-200mm (6”-8”) is required between cleaner and

chute wall to prevent clogging of material.

NOTE: For U-Type cleaners using UST Tensioners, proceed to Steps 2U - 7U.

For U-Types using J-Bolt Tensioners, skip ahead to Steps 2J - 8J on Page 10.