19

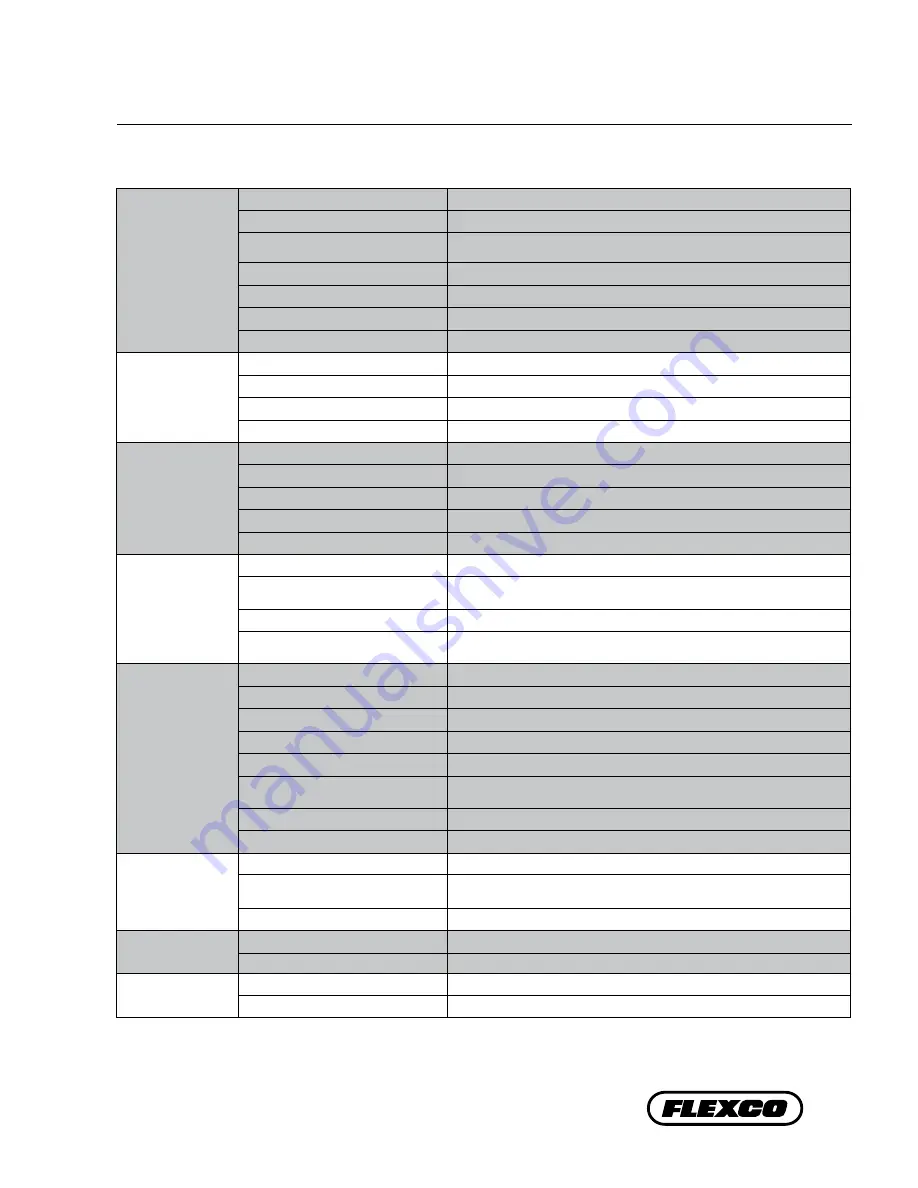

Section 7 - Troubleshooting

Problem

Possible Cause

Possible Solutions

Vibration

Cleaner secure bolts not set

Ensure all locking nuts are tight (Loctite)

Cleaner not set up correctly

Ensure cleaner set up properly (1°-3° into belt)

Belt tension too high

Ensure cleaner can conform to belt, or replace with alternate Flexco

secondary cleaner

Belt flap

Introduce hold-down roller to flatten belt

Cleaner over-tensioned

Ensure cleaner is correctly tensioned

Cleaner under-tensioned

Ensure cleaner is correctly tensioned

Nylon bearing worn out or missing

Replace nylon bearing

Material buildup on

cleaner

Cleaner not set up correctly

Ensure cleaner set up properly (1°-3° into belt)

Buildup on chute

Ensure cleaner is not located too close to back of chute, allowing buildup

Cleaner being overburdened

Introduce Flexco precleaner

Excessive sticky material

Frequently clean unit of buildup

Damaged belt cover

Cleaner over-tensioned

Ensure cleaner is correctly tensioned

Cleaner blade damage

Check blade for wear, damage and chips, replace where necessary

Attack angle not correct

Ensure cleaner set up properly (1°-3° into belt)

Material buildup in chute

Frequently clean unit of buildup

Stop collar in incorrect position

Check stop collar tabs are not resting against slide plate

Cleaner not

conforming to belt

Cleaner not set up correctly

Ensure cleaner set up properly (1°-3° into belt)

Belt tension too high

Ensure cleaner can conform to belt, or replace with alternate Flexco

secondary cleaner

Belt flap

Introduce hold-down roller to flatten belt

Cleaner cannot conform

Ensure cleaner can conform to belt, or replace with alternate Flexco

secondary cleaner

Material passing

cleaner

Cleaner not set up correctly

Ensure cleaner set up properly (1°-3° into belt)

Cleaner tension too low

Ensure cleaner is correctly tensioned

Cleaner blade worn/damaged

Check blade for wear, damage and chips, replace where necessary

Cleaner being overburdened

Introduce Flexco precleaner

Belt flap

Introduce hold-down roller to flatten belt

Cleaner cannot conform

Ensure cleaner can conform to belt, or replace with alternate Flexco

secondary cleaner

Blade in backwards

Install blade correctly and set correct tension

Stop collar in incorrect position

Check stop collar tabs are not resting against slide plate

Damage to

mechanical fastener

Incorrect cleaner blade selection

Change blade type to accommodate fastener style (UC or UF)

Belt not skived correctly

Spot and redo splice correctly, lowering the profile flush or below belt

surface

Stop collar in incorrect position

Check stop collar tabs are not resting against slide plate

Missing material in

belt center only

Cleaner pole located too high

Ensure cleaner set up properly (1°-3° into belt)

Cleaner blade worn/damaged

Check blade for wear, damage and chips, replace where necessary

Missing material on

outer edges only

Cleaner pole located too low

Ensure cleaner set up properly (1°-3° into belt)

Cleaner blade worn/damaged

Check blade for wear, damage and chips, replace where necessary