69

All work involving the 240 volt mains electricity supply must be carried

out by a qualifi ed electrical contractor with full knowledge of the relevant

safety regulations.

The vacuum cleaner will not start

CV 200 Thermal protector

If this happens - unplug the main power cord to reset the vacuum

cleaner. Wait 5-10 minutes to allow the machine to cool down. While

you are waiting, check the hose, dust bag and fi lter to be sure that noth-

ing is blocking the fl ow of air through the machine. The vacuum cleaner

should now start again. If the cut-out trips again, you need to get a serv-

ice fi rm to remedy the fault.

CV 300 / CV 400 RRC Thermal protector

The red fl ashing light indicates that the cleaner has become overheated.

The cleaner stops automatically. Wait 5-10 minutes to allow the machine

to cool down. While you are waiting, check the hose, dust bag and fi lter

to be sure that nothing is blocking the fl ow of air through the machine.

Reset the cleaner. This is done by pushing the reset button at display for

at least 3 seconds.

Other troubleshootings

• Are you using the correct hose?

Only the original hoses fi t correctly.

• Does the vacuum cleaner start when you try a different vacuum sock-

et? If so, there is a fault in the electrical connection to the fi rst socket.

Unscrew the socket and check the connection at the back.

• Is the power supply connected to the vacuum unit?

• Is there power at the socket?

• Is the low-voltage lead connected to the vacuum unit?

• The batteries to the radio remote control (RRC version of vacuum

cleaner) may have been discharged. Replace the two batteries with

new ones, type CR2 3V.

The vacuum cleaner will not stop

• Has a metal object become lodged in one of the vacuum sockets

causing the pins to become fused?

Poor suction power

• Are all the vacuum sockets closed properly?

• Has something become jammed in one of the vacuum sockets?

• Is the container lid closed properly?

• Is the gasket between the container and the lid in place?

• Is it damaged?

• Is the pipe system blocked?

• Is the dust bag full or sealed? Model CV 300 provides notifi cation by

means of a message on the panel.

• Is the fi lter sealed? Model CV 300 provides notifi cation by means of

a message on the panel. Model CV 400 RRC provides notifi cation by

means of a message on the panel.

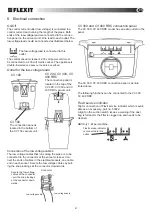

CV 300 / CV 400 RRC display

The CV 300 / CV 400 RRSmodel has a display that shows relevant sta-

tus.

Start/stop switch - fi xed green light

When the start switch is pushed or the hose is connected to the wall

socket, a green steady LED-light will be lightened at the display. The

green light indicates that the cleaner are running under normal conditions.

Dust Bag/bag fi lter indicator - fl ashing yellow light

When the yellow LED-indicator starts to fl ash during operation, the clean-

er tells you that it is time to clean the bag fi lter or/and replace the dustbag.

The yellow fl ashing light will be lightened efter every 8 operation hours of

the cleaner. If the yellow light are fl ashing do like this: Turn off the cleaner

10 Troubleshooting

EN

by the hose handle (remote versions) or remove the suction hose from

the wall inlet or by pushing the on/off switch at the display. Then check if

the bag fi lter/dustbag are clogged. Replacement are descriped in chapter

7.1,7.2,7.3 and 7.4. When the fi lters are cleaned/replaced, you must per-

form a reset of the cleaner. This is done by pushing the reset button at the

display for at least 3 seconds.

Reduced airfl ow indicator - fi xed yellow light

A yellow fi xed light at the display indicates that the airfl ow through the

vacuum cleaner is reduced. After 30 seconds operation with reduced

airfl ow, the vacuum motor will be shot down in order to prevent damage

to the motor. If the fi xed yellow light is alight and the motor has been

shot down, do like this: Check the bag fi lter or/and dust bag (see chapter

7.1,7.2,7.3 and 7.4) to see if anything is blocking the airfl ow. Remove the

material causing the fi xed yellow light to indicate. When this is done, you

must reset the cleaner. This is done by pushing the reset button at the

display for at least 3 seconds.

Time for service indicator - fi xed red light

When the red fi xed light indicator is activated, the motor stops/will not

start. The purpose of the fi xed red light is to inform you that it is time to

order service of the cleaner. The run time counter in the cleaner has

counted that the allowed amount of run time has passed. You must now

contact an authorised service workshop and let them perform a service of

the cleaner and to reset the run time counter. You can reset the machine

temporarily and run the motor for an additional running hour by pushing

the reset button for at least 3 seconds. After this 1 extra running hour, a

service must be performed - otherwise the machine will not start again.

Overheating indicator - fl ashing red light

The red fl ashing light indicates that the cleaner has become overheated.

The cleaner stops automatically. Wait 5-10 minutes to allow the machine to

cool down. While you are waiting, check the hose, dust bag and fi lter to be

sure that nothing is blocking the fl ow of air through the machine. Reset the

cleaner. This is done by pushing the reset button at the display for at least

3 seconds.

Service and spare parts

If you need a service or spare parts, contact your local dealer. In such

circumstances, it is always useful if you can give the technical data

shown on the rating plate of the vacuum unit. The rating plate is adjacent

to the lead intake. It’s a good idea to copy this data here so that it is

readily to hand.

Model: ............................................................................................

Product no.: ....................................................................................

Serial no.: .......................................................................................

Date of purchase: .........................................................................

(please keep your receipt)

WARNING!

Blockages can occur if:

a) the tools and accessories are not used as di rect ed at

all

times.

b) wet or damp carpets are vacuumed.

c) foreign objects are vacuumed up when the tools are

not

affi xed to the hose.

d) the wall sockets are not kept open until the system

motor stops completly

e) the

fi lter and bags are not regularly cleaned and

replaced as per manufacturers in struc tions.

NB! Blockages are caused by misuse and are not covered by the

guarantee or warranty.

Summary of Contents for CV 100

Page 73: ...73 ...

Page 74: ...74 ...

Page 75: ...75 ...

Page 76: ...Flexit AS Televeien 15 N 1870 Ørje Norway www flexit no ...