7

3 Installation

the unit is designed for indoor installation.

3.1 Inspection/Maintenance

The unit must be installed with space for service and

maintenance such as filter replacement and cleaning

the fans and exchanger. It is also important for the unit

to be located so that the electrical cabinet is easily ac-

cessible for electrical connection, troubleshooting and

future component replacement.

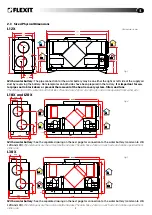

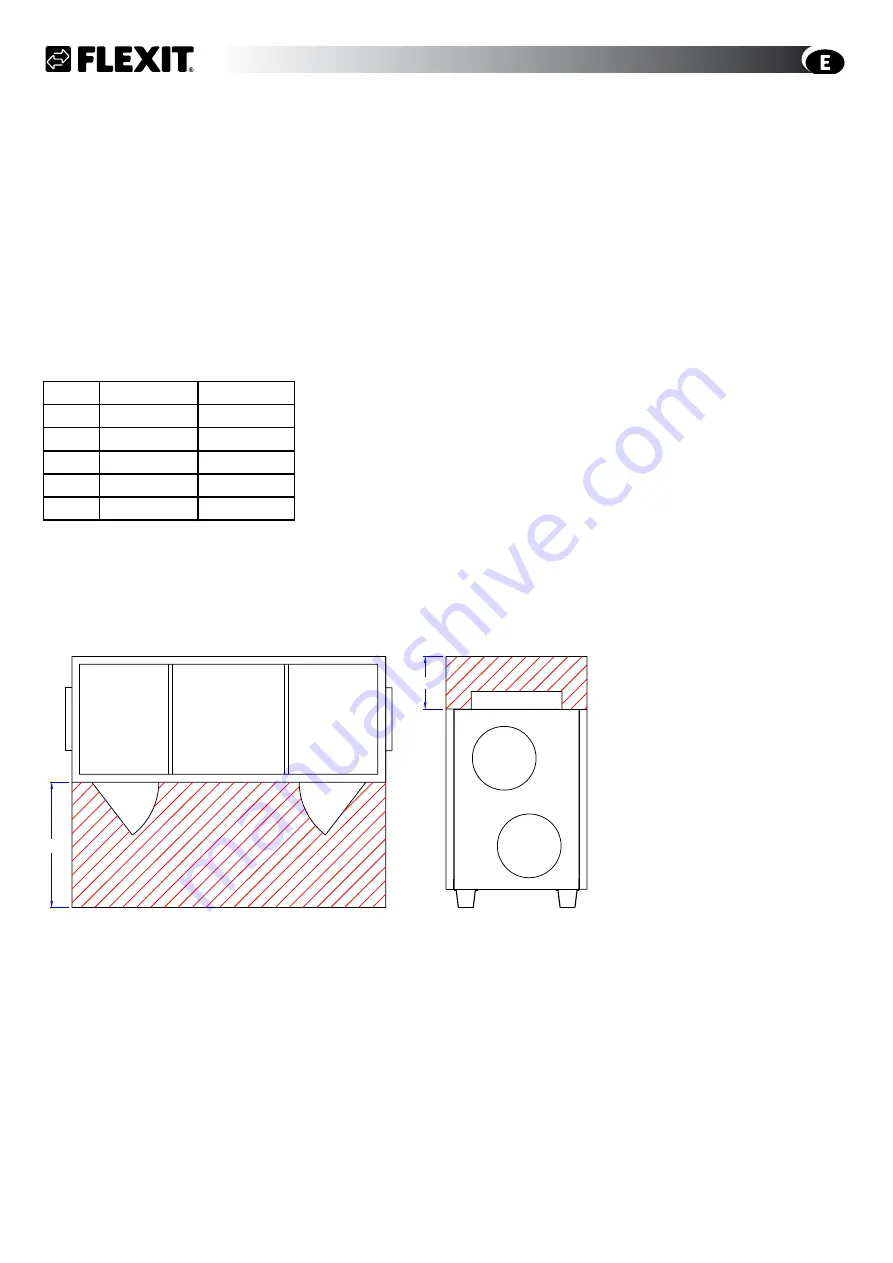

3.2 Space Required

Type

A

B

L12

550 mm

400 mm

L18

1000 mm

500 mm

L20

1000 mm

500 mm

L30

1000 mm

500 mm

L50

1400 mm

100 mm

See the separate dimensioned drawing for connection

of the water battery (pipe location), Chap. 2.3.

These are minimum requirements that only take service

needs into account. If other statutory requirements re-

quire a greater distance, they must be complied with, for

example for electrical safety.

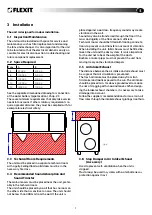

3.3 technical Room Requirements

The unit must be placed in a separate technical room

with a gully. Ceiling/floor/walls/doors must be in the

necessary fire class.

3.4 Recommended Sound Absorption and

Sound transfer

The main silencers must be placed near the unit, prefer-

ably in the technical room.

The unit should be placed by a wall that has no room on

the other side that is sensitive to noise. The unit should

not be less than 400 mm from the wall. If the unit is

placed against a wall, low-frequency sound may create

vibrations in the wall.

Sound may also be transferred through the floor if the

mass and rigidity of the floor are not sufficient.

Technical rooms should be fitted with floating concrete

floors to prevent sound transfer on account of vibration.

When installing the unit, fabric bosses must be fitted be-

tween the unit and the duct system. It is also important

for the unit not to bear the weight of the ducts.

Busbars or water pipes must not prevent the unit from

moving freely on the vibration dampers.

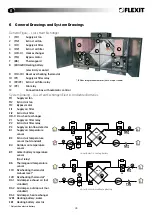

3.5 Air Intake/exhaust

The distance between the air intake and air exhaust must

be so great that air circulation is prevented.

The fresh air intake must be placed away from traf-

fic/smoke/dust/walls exposed to the sun. The air intake

should be placed min. 1 m above ground level to reduce

the risk of clogging with snow and leaves. When design-

ing the intake/exhaust chambers, it is necessary to take

drainage into account.

Follow the suppliers’ recommendations for max./min. air

flow rates through the intake/exhaust gratings/roof hats.

3.6 Stop Damper in Air Intake/exhaust

(Accessory)

Used to prevent self-ventilation when the unit is

stopped.

Must always be used in systems with water batteries as

protection against frost.

B

A

Fig. 8

Summary of Contents for L12 X

Page 22: ...22 ...

Page 23: ...23 ...

Page 24: ...Flexit AS Televeien 15 N 1870 Ørje www flexit com ...