PAGE 50 — EHHNK5 RIDE-ON TROWEL • OPERATION MANUAL — REV. #3 (05/03/21)

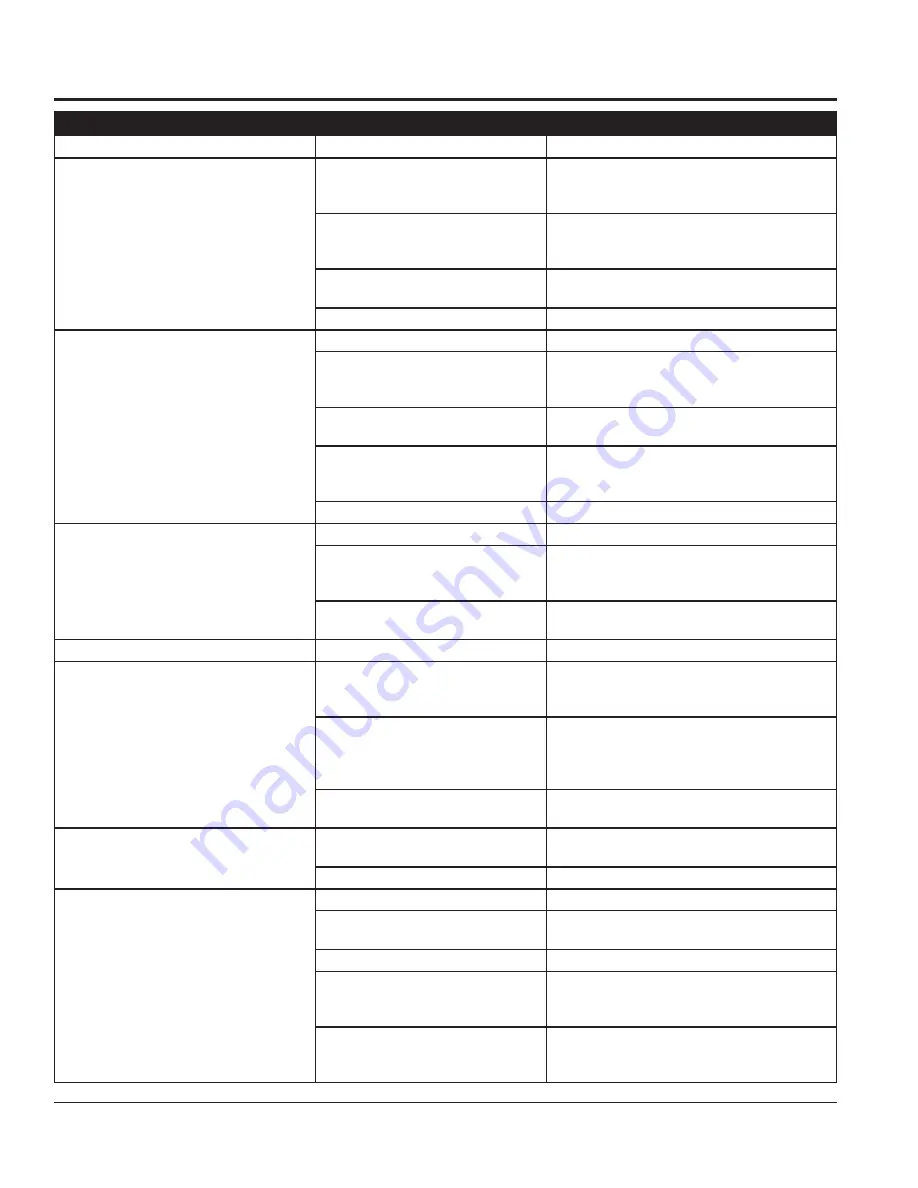

TROUBLESHOOTING (TROWEL)

Troubleshooting (Ride-On Mechanical Trowel) - continued

Symptom

Possible Problem

Solution

Lights (optional) not working.

Wiring?

Check all electrical connections in the lighting circuit.

Verify wiring is in good condition with no shorts. Replace

defective wiring or components immediately.

Lights?

If +12VDC is present at light fi xture connector when light

switch is activated and light does not turn on, replace light

bulb.

Bad switch?

Check the continuity of light switch. Replace light switch if

defective.

Bad fuse?

Check fuse. Replace fuse if defective.

Retardant spray (optional) not working.

Retardant?

Check retardant level in tank. Fill tank as required.

Wiring?

Check all electrical connections in the spray pump circuit.

Verify wiring is in good condition with no shorts. Replace

defective wiring or components immediately.

Bad switch?

Check the continuity of both left and right spray switches

(palm handles). Replace spray switch if defective..

Bad spray pump?

If +12VDC is present at pump connector when spray

switch is activated and pump does not operate, replace

spray pump.

Bad fuse?

Check fuse. Replace fuse if defective.

Steering is unresponsive.

Blade speed out of adjustment?

See section on blade speed adjustment.

Steering linkage out of adjustment?

Adjust the connecting linkage found at the base of the

handle. Contact your MQ fi eld service manager for

instructions.

Worn components?

Check for wear of steering bearings and linkage

components. Replace if necessary.

Operating position is uncomfortable.

Seat adjusted for operator?

Adjust seat with lever located on the front of the seat.

Power head on Electric Pitch (optional) not working.

Broken or loose parts?

If the motor runs and the pitch is not affected, parts inside

the power head may be loose or broken. Return power

head to dealer for service.

Wiring?

Check all electrical connections and wiring. Check the

continuity at the power head unit. Verify that there is

voltage present at the power head switch with the key

switch in the “on” position.

Switch?

Check the continuity of the switch. If switch is

malfunctioning, replace immediately.

Linkage on Twin Pitch not working.

Crank handles?

Make sure that both crank handles are pushed down as

far as possible to ensure that the linkage is engaged.

Broken part?

Replace all broken parts immediately.

Clutch slipping or sluggish response to engine

speed change.

Worn belts?

Replace belt.

Clutch out of adjustment?

Adjust per instructions in maintenance section of this

manual.

Worn or defective clutch parts?

Replace parts as necessary.

Worn bearings in gearbox?

Rotate input shaft by hand. If shaft rotates with diffi culty,

check the input and output shaft bearings. Replace as

necessary.

Worn or broken gears in gearbox?

Verify that the gearbox shaft rotates when the input shaft

is rotated. Replace both the worm and worm gear as a

set.