30

1300 353 986

flextool.com.au

Troub

leshooting (Er

ror Codes)

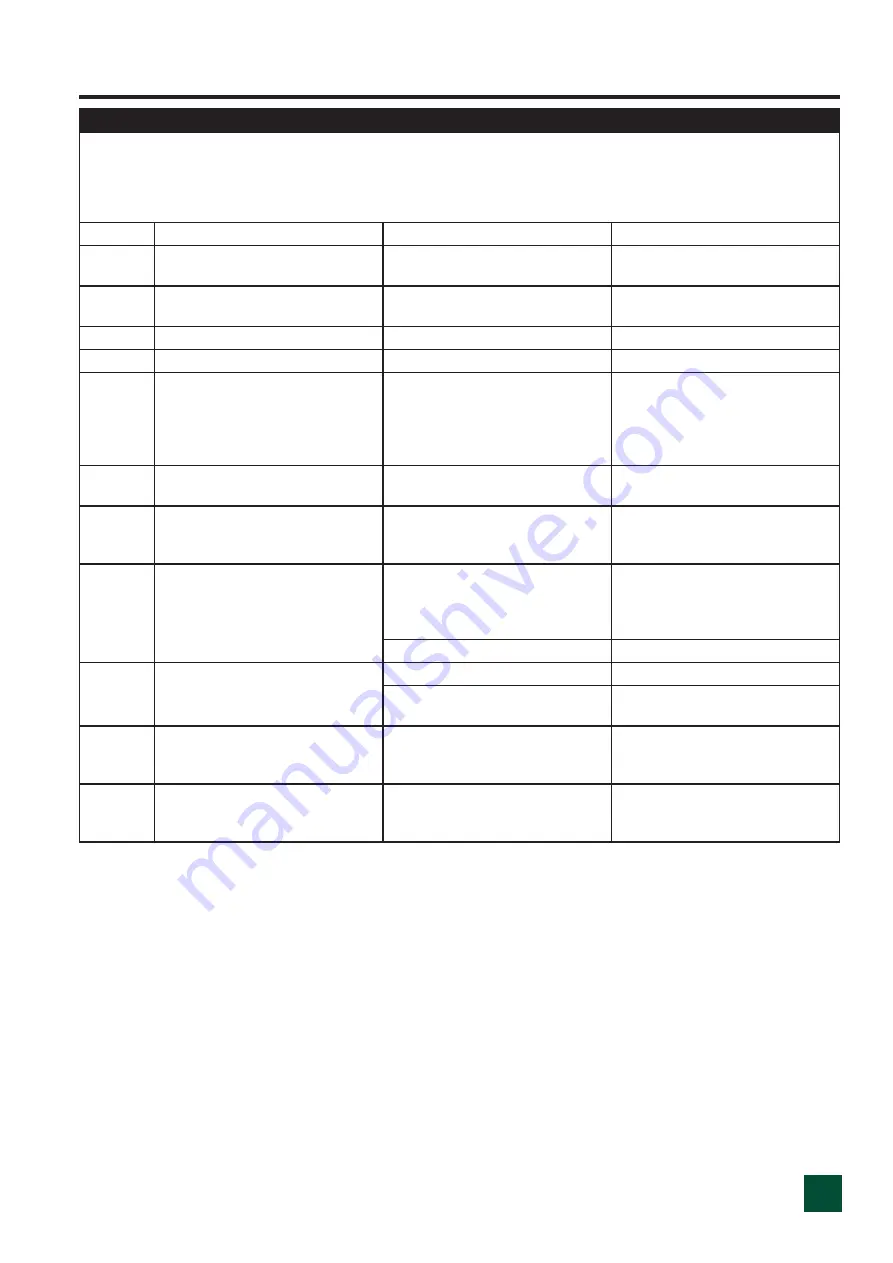

The machine controller detects a wide variety of faults or errors. Diagnostic information can be obtained on the 3100R fuel gauge display where an error code in the format

“Err ##”. The troubleshooting chart below describes the error code faults and their possible causes. Whenever a fault is encountered the first action should be to turn off the ignition

and push in the E-stop button. Then pull out the E-stop button and turn the ignition back on to see if the fault clears. This is the RESET procedure: If the error code does not clear

after the machine RESET, turn off the ignition switch and remove the 35-pin connector. Check the connector for correction or damage, clean it if necessary, and reinsert it. If the

error is still seen then the wiring and connections on the machine should be checked for breakages or loose connections. The table below should be used as a reference once the

above checks have been carried out.

Error Code

Symptom

Possible Problem

Solution

1

HW fail-safe

Motor fault voltage (hardware failure)

Motor voltage does not correspond to

throttle request?

Check for short in motor or motor wiring.

10

Main brake driver over current.

Short circuit or overloaded controller

driver?

Check brake controller driver. Reference

Curtis controller owner's manual.

15

Main current dropped.

Main contactor failed to open?

Clean the contactor switch.

17

Main contactor welded.

Main contactor fault / failed to close?

Replace contactor.

33

Supervisor DIR check fault.

Program issue?

If fault is on an external signal, check

that signal first. If no problem with

the external signal, likely indicates an

internal controller fault. Reference Curtis

controller owner's manual

34

External supply fault.

Under voltage?

Check control wiring circuit,

potentiometer wiring in particular.

36

EM-brake driver open drain.

Hold voltage set at 90%?

Check brake electrical connectors.

Check continuity. Replace motor brake

if failed.

54

Pre-charge failed/fault.

Low battery voltage?

Check battery voltage. 25V (11/12V per

battery) is good condition, 22V (9/10V

per battery) or lower is bad battery

condition.

Short circuit on traction motor outputs?

80

HPD sequencing

HPD fault present > 10 seconds.

Misadjusted throttle?

Adjust. See maintenance section.

Broken throttle potentiometer or throttle

mechanism?

Replace.

92

Traction motor open / not connected.

Controller cannot see the motor.

Short circuit in the motor?

Check the resistance across the motor

leads.

99

Undervoltage cutback.

Battery voltage < undervoltage

threshold?

Check connection at battery or controller.

Check no corrosion on the battery

terminals.

Quick checks if no reading on the fuel gauge and the machine does not operate:

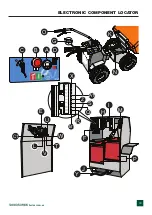

1. Check 10-amp ignition fuse located on the backside of the control panel. Reference 'Electronic Component Locator" drawing.

2. Check 100-amp main fuse*located on the backside of the control panel. Reference 'Electronic Component Locator" drawing.

2. When changing the 100-amp fuse, ensure that the positive battery cable is fully disconnected. Electrical maintenance should be carried out

by a qualified person.

ERROR CODES