Printed in Canada

June 14, 2007

Section 2 - Hydraulic Fan Group

01523r7.wpd

Page 2-5

Figure 5

Figure 6, Push

Position

Figure 7, Pull

Position

Figure 8, Neutral

Position

Some designs will require the removal of

capscrews and 2 half-moon rings or

equivalents (links); the pulley can then be slid

toward the hub to give easier access to the

hydraulic fittings, as shown in

Figure 4

.

Figure 4

G.

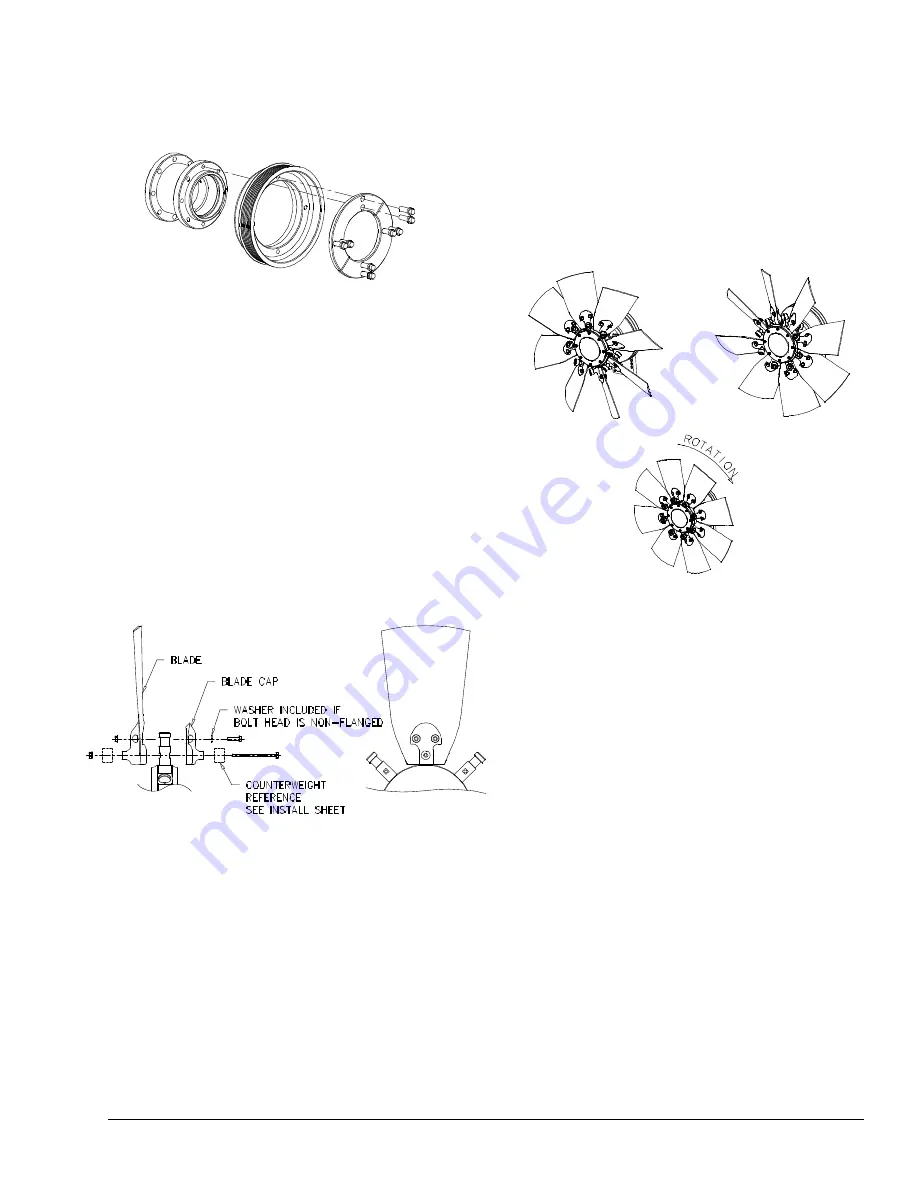

If the primary operation of the fan is to “pull” air

towards the engine, then the blades must be

mounted with the concave surface towards the

engine (assuming clockwise rotation of the fan). If

the primary operation of the fan is to “push” air

away from the engine, then the blades must be

mounted with the concave surface away from the

engine. The illustrations that follow show a fan that

primarily “pulls” air.

H.

The quantity and location of the counterweights

vary depending upon application. Please refer to

the install sheet supplied with your fan. Insert the

supplied 1/4" NC long hex bolt through the lower

hole in the blade cap, the blade shaft and the

blade. Tighten the assembly to the blade shaft

using the supplied 1/4" NC flanged lock nut.

I.

Insert the 1/4" NC short flange-head bolts through

the upper holes in the blade caps and blades.

Tighten the blade caps to the blades using the

supplied 1/4" NC flanged lock nuts. Regular hex-

head bolts with washers may be supplied in place

of flange-head bolts.

Note:

If any of the supplied flanged lock nuts are lost

or need to be replaced, they may be

substituted with grade 8 flanged nuts.

Loctite® 242 or equivalent must be applied

to the bolt if lock nuts are not used.

J.

Rotate fan by hand in “PUSH”, “PULL” and

“NEUTRAL” modes (as shown in

Figure 6

,

Figure 7

&

Figure 8

respectively) to ensure that

the blade does not hit any obstructions such as

bolts, brackets, or braces. Secure remaining fan

blades. Carefully torque blade bolts with a

certified torque wrench to the following

specification:

1/4" - 20 NC to 9 ft./lbs.

WARNING - DO NOT OVER TORQUE

K.

Rotate fan blades once again by hand in

“NEUTRAL”, “PULL” and “PUSH” modes to

ensure that the blades do not hit any obstructions

such as bolts, brackets, or braces.

L.

Tighten fan belts and replace all fan guards and

safety equipment.

M.

Attach the "WARNING" label to the machine, on

a housing or guard, in a location near the fan

where it can be easily seen.

N.

Attach the "ATTENTION" label to the machine, in

the engine compartment, near the hub assembly

or another visible area.

2.2.2. Hydraulic Control Installation Guide

The Flexxaire

®

FX Fan assembly requires a hydraulic

source and valving to operate.

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...