Page 2-8

01523r7.wpd

Section 2 - Hydraulic Fan Group

June 14, 2007

Printed in Canada

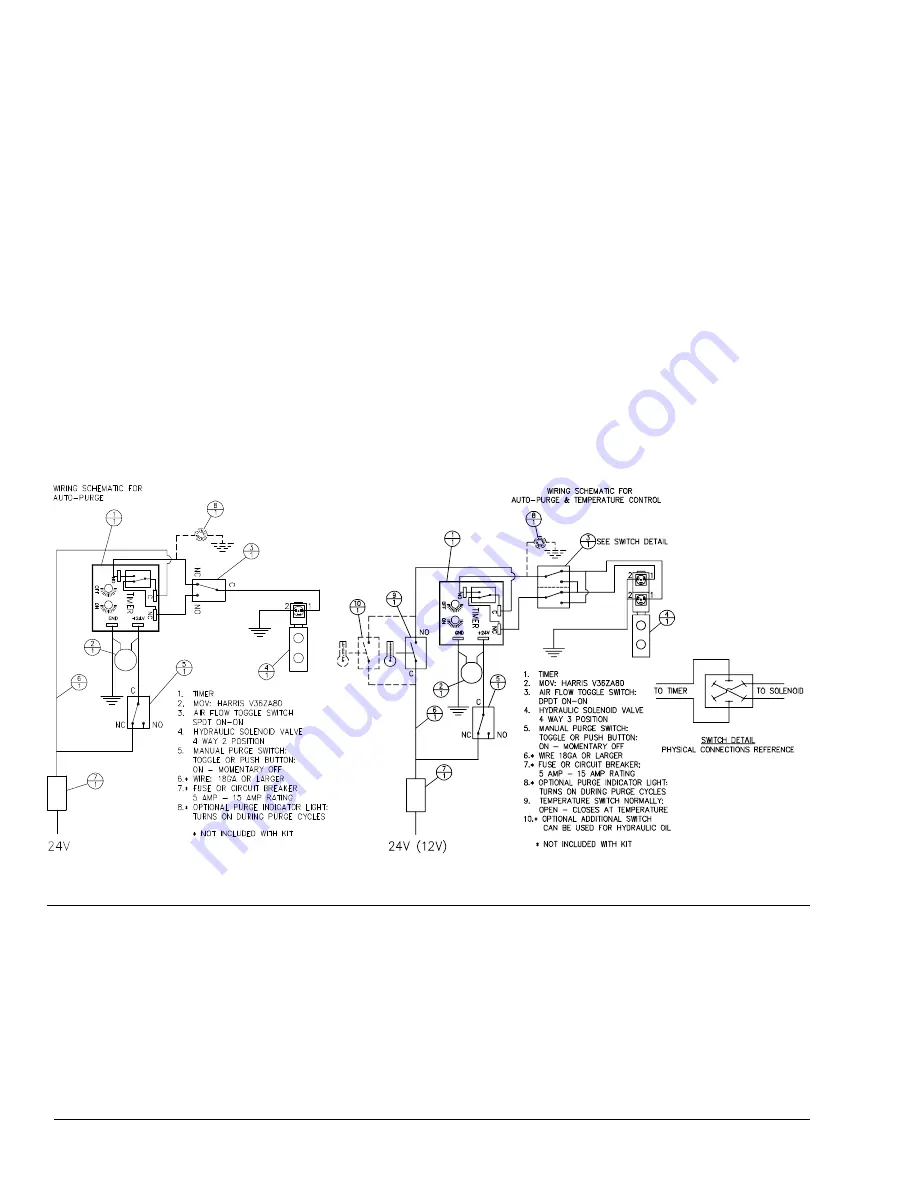

Figure 12, Temperature Control Schematic

A.

Find an appropriate location for switches and timer

on operator’s console.

B.

Mount timer onto backside of console.

NOTE:

Timer comes with 2 strips of double-sided

tape. Clean surface with rubbing alcohol

or equivalent prior to mounting timer.

C.

Mount switches and switch decals.

D. Step only applicable for 3-Position control kit.

Install temperature switch into the engine’s water

jacket.

NOTE 1:

Temperature switch(es) are used to

put the fan into full pitch at their rated

temperature. The fan remains in full

pitch until temperature drops

approximately 8

?

F below rated

temperature. Switch(es) for different

temperature ranges are available

from Flexxaire

®

.

NOTE 2:

Fans will go to pitch based on engine

temperature; however, additional

temperature switches can be added

for hydraulic oil or any other fluid as

required. Install additional switches

parallel to the engine temperature

switch as shown in

Figure 11

.

Contact Flexxaire

®

for ordering

additional temperature switches.

E.

Make wiring connections as per

Figure 11

or

Figure 12

, depending on control kit be used.

NOTE 1:

Hydraulic solenoid connector

(Item 4) may contain a diode.

Polarity is important!

Connect

pin 2 to ground and pin 1 to

power source.

NOTE 2:

MOV (Harris V36ZA80) (Item 2) is

used to protect timer electronics

from voltage surges found in

heavy equipment electrical

systems.

Figure 11, Non-Temperature Control

Schematic

2.2.2.6. Hydraulic Control Set-Up

The following control set-up is specific to Flexxaire

®

control groups but would apply to similar set-ups.

A. Step only applicable for 3-Position control kit.

Install a jumper wire across temperature switch

leads, to by-pass temperature switch (this will allow

setup to be completed without having engine hot).

B.

Start engine to develop hydraulic pressure.

C.

Toggle Air Flow switch (Item 3) several times to

purge air from newly installed hydraulic lines.

NOTE:

If air exists within the hydraulic lines, the

fan will take longer to purge.

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...