Printed in Canada

June 14, 2007

Section 2 - Hydraulic Fan Group

01523r7.wpd

Page 2-11

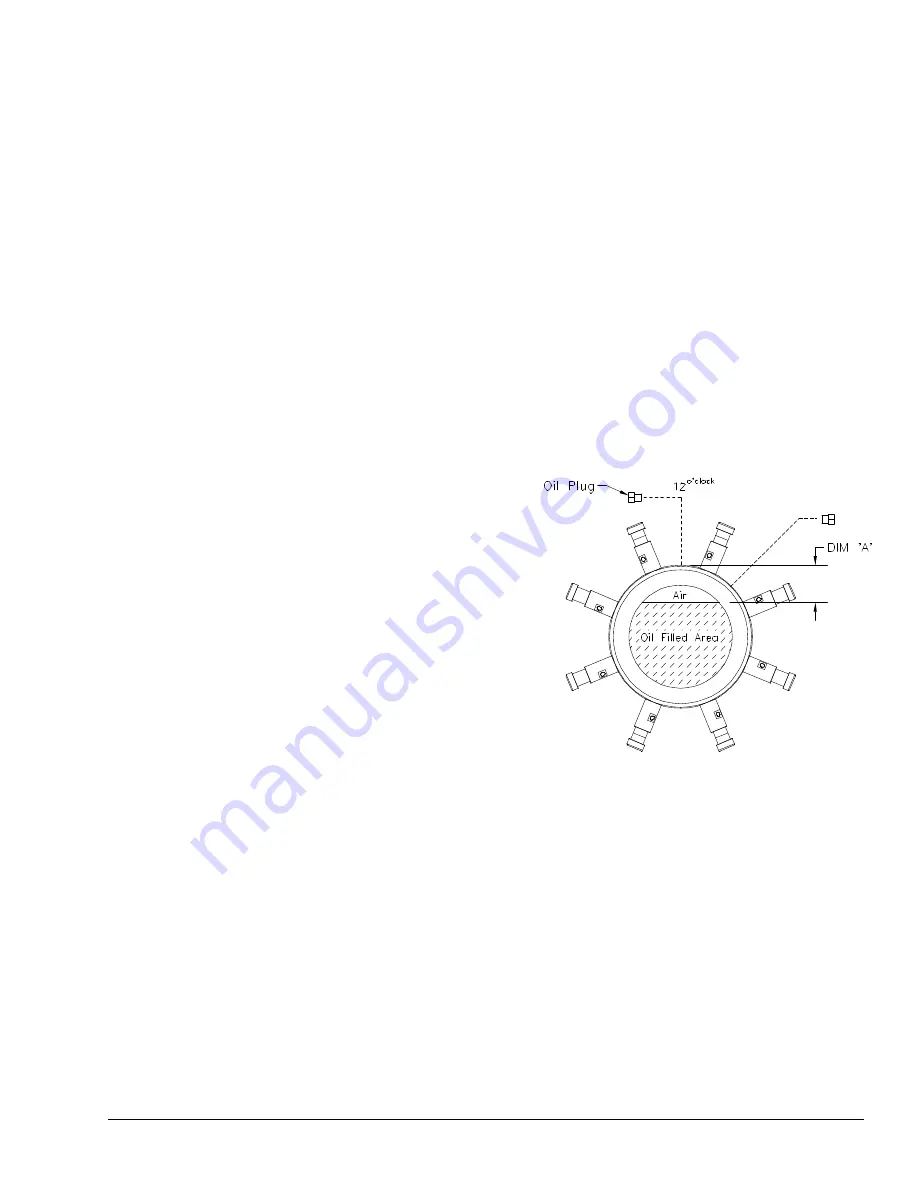

Figure 13

2.3.2. Checking Oil Level and

Adding/Draining Oil

2.3.2.1 Checking Oil Level

A.

Rotate the hub until one of the oil drain plugs is at

the 12:00 position and the other at the 2:00

position. As indicated in

Figure 13

.

B.

Remove the oil drain plug at the 12:00 position.

C.

Insert an appropriate dipstick into the hub through

the drain plug at 12:00. (Flexxaire does not supply

a dipstick.)

D.

Measure the distance from the top of the hub

down to the oil level. Oil level should be as

indicated in

2.3.2.4.

E.

If oil level is low, add until desired distance is

achieved.

CAUTION! DO NOT OVER FILL HUB.

An air space is required to allow for oil expansion, as

shown in

Figure 13

. Failure to do so will result in seal

failure.

F.

Reinstall the oil drain plug.

G.

Check for leaks.

CAUTION: Low oil level may indicate a leak.

2.3.2.2

Adding Oil To Fan

A.

Rotate the hub until one of the oil drain plugs is at

the 12:00 position and the other at the 2:00

position. As indicated in

Figure 13

.

B.

Remove both of the oil drain plugs.

C.

Fill hub with oil till desired “Air Space” distance is

achieved as per

2.3.2.4.

CAUTION! DO NOT OVER FILL HUB.

An air space is required to allow for oil expansion, as

shown in

Figure 13

. Failure to do so will result in seal

failure.

D.

Reinstall the oil drain plugs.

E.

Check for leaks.

2.3.2.3.

Draining Oil From Fan

A.

Rotate the hub until one of the oil drain plugs is at

the 12:00 position and the other at the 2:00

position. As indicated in

Figure 13

.

B.

Remove both of the oil drain plugs.

C.

Slowly turn fan until oil starts to flow from the first

hole. Capture in suitable container.

D.

When oil flow stops, rotate the hub until it flows

again. Repeat until one hole is at the 6:00 position

and the other at the 4:00 position and all oil has

drained from hub.

2.3.2.4.

Dimension ‘A’ - Top of Hub to Top of Oil

Dim ‘A’ = 3 1/4" - 3 3/8"

Summary of Contents for FX 2000 Series

Page 2: ...Page 0 2 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 4: ...Page 0 4 01523r7 wpd Hydraulic Manual June 14 2007 Printed in Canada...

Page 6: ...Page 1 2 01523r7 wpd Section 1 General Information Overview June 14 2007 Printed in Canada...

Page 10: ...Page 2 2 01523r7 wpd Section 2 Hydraulic Fan Group June 14 2007 Printed in Canada...