Not included

on all units

)

s

(

t

e

lt

u

o

k

n

a

t

o

t

e

p

i

P

Manual OPEN/

CLOSE valve

Drain me and

Drain interval

Filter access

Clean regularly,

see Fig. 13.

Improperly grounded electrical

components are shock hazards.

Make sure all the components are

properly grounded to prevent

death or serious injury.

9. Make sure proper overload protec on for the

motor is installed.

Wiring Installa on

Install power leads into terminals opposite motor

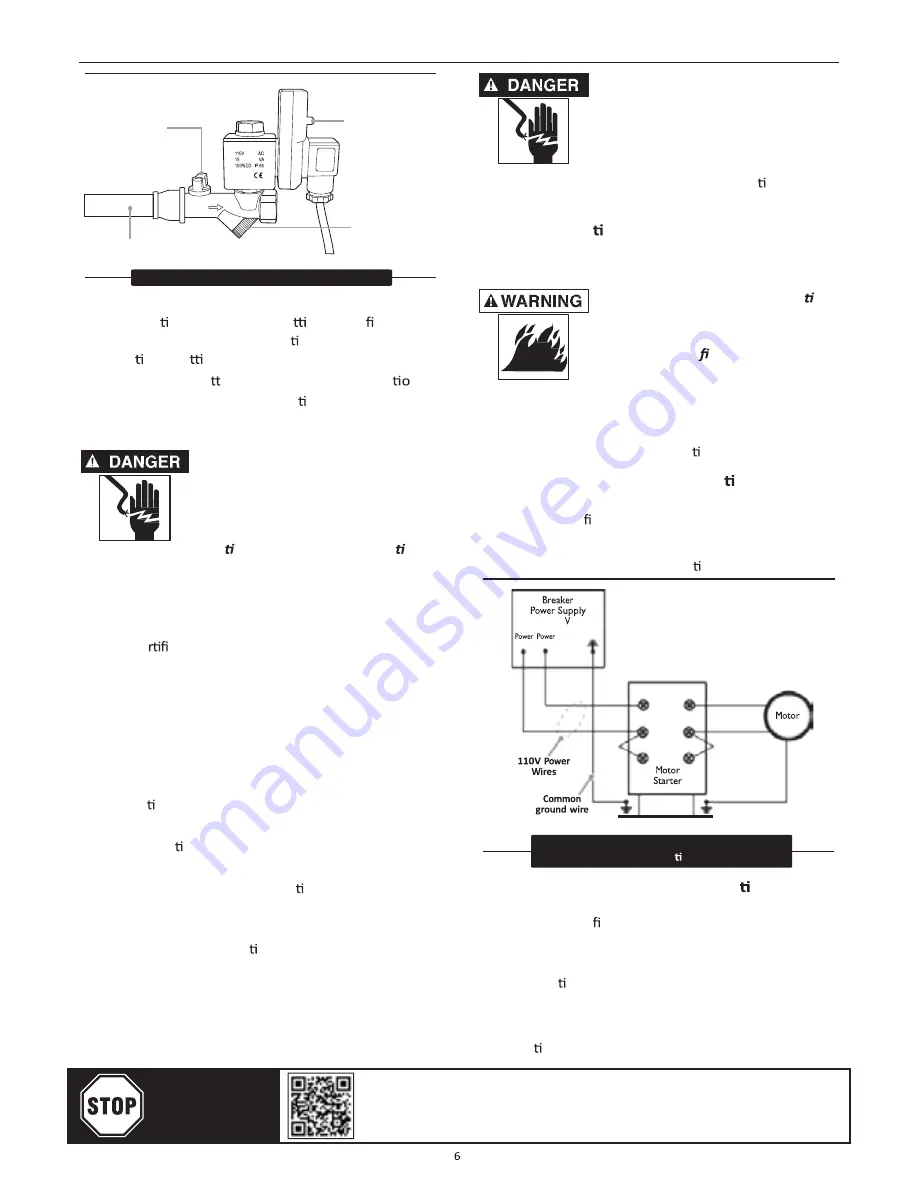

Figure 4: Auto Drain Feature

1. Plug auto drain into 120V outlet.

2. Set mers to desired se ngs. See gure 4.

If drain is used for mul ple units, increase

mer se ngs as needed.

3. Use test bu on to check proper opera n.

wires.

When wiring unit with magne c

starter, do not install power

directly to pressure switch to

avoid possible re and property

damage.

Refer to maintenance sec

.

e

r

a

c

r

e

p

o

r

p

r

o

f

n

o

Electrical Safety

Be sure only trained and

authorized personnel install and

maintain this compressor in

accordance with all applicable

federal, state and local codes,

standards and regula ons. Follow all NEC (Na onal

Electric Code) standards, especially those concerning

equipment grounding conductors.

1. Follow all NEC and local codes for electrical wiring.

Allow only authorized Flexzilla service person or

ce ed electrician to install electrical components.

2.

e

r

u

s

e

k

a

m

d

n

a

t

i

u

c

ri

c

d

e

t

a

ci

d

e

d

n

o

t

i

n

u

t

u

P

no other electrical equipment is wired into it.

Failure to wire unit on independent circuit can

cause circuit overload and/or imbalance in

motor phasing. Install proper No Fuse Breaker

(NFB) according to kW output of compressor.

3. Ensure incoming service has adequate ampere

ra ng.

4. Ensure supply line has the same electrical char-

acteris cs (voltage, cycles and phase) as the

electric motor.

5. Refer to amp load informa on on motor tag and

use correctly sized wiring.

Be sure to consider

distance between power supply and machine.

6. Install surge protec on device between power

supply and compressor motor.

7. Make sure to install properly sized breakers and

fuses.

8. The unit must be properly grounded. DO NOT

connect ground wire to air or cooling lines.

e

t

a

u

q

e

d

a

si

g

n

ir

i

w

l

a

n

r

e

t

n

i

d

n

a

y

l

p

p

u

s

r

e

w

o

p

e

r

u

s

n

E

according to voltage and frequency stated on motor

nameplate and starter. Voltage should not vary more

than 12% to ensure proper opera

.r

o

s

s

e

r

p

m

o

c

f

o

n

o

S

(Flexzilla Pro 5 HP)

S

(Flexzilla Pro 7.5-10 HP)

ingle Phase Motors - No Magne c Starter

1. Connect rst power lead to 1L1.

2. Connect second power lead to 3L2.

3. Connect ground wire to exis ng motor ground wire.

m

a

r

g

a

i

D

g

n

ir

i

W

e

s

a

h

P

e

l

g

n

i

S

:

5

e

r

u

g

i

F

without magne c starter

Single Phase Motors - With Magne c Starter

1. Connect rst power lead to 1L1. Leave exist-

ing jumper wire installed. See Figure 6.

2. Connect second power lead to 3L2. Leave

exis ng jumper wire installed.

3. Connect ground wire to ground lug.

4. Ensure all wiring and terminals are properly

ghtened.

220

1

2

1

2

3

4

5

6

Operat ing, Service and Warranty Manual

Flexzilla® Pro Piston Air Compressors with Silencer™, Electric Operated

YOU MUST

REGISTER TO

ACTIVATE

WARRANTY

Scan or go to website hosted below:

www.eatoncompressor.com/warranty

Warranty only valid by following conditions expressed in the Warranty Statement section of this Air Compressor Manual.