FT-112(D) Panel Weighing Indicator, Technical Manual, Rev.1.0.0, May 2019

Page

8

of

170

RS

4

22

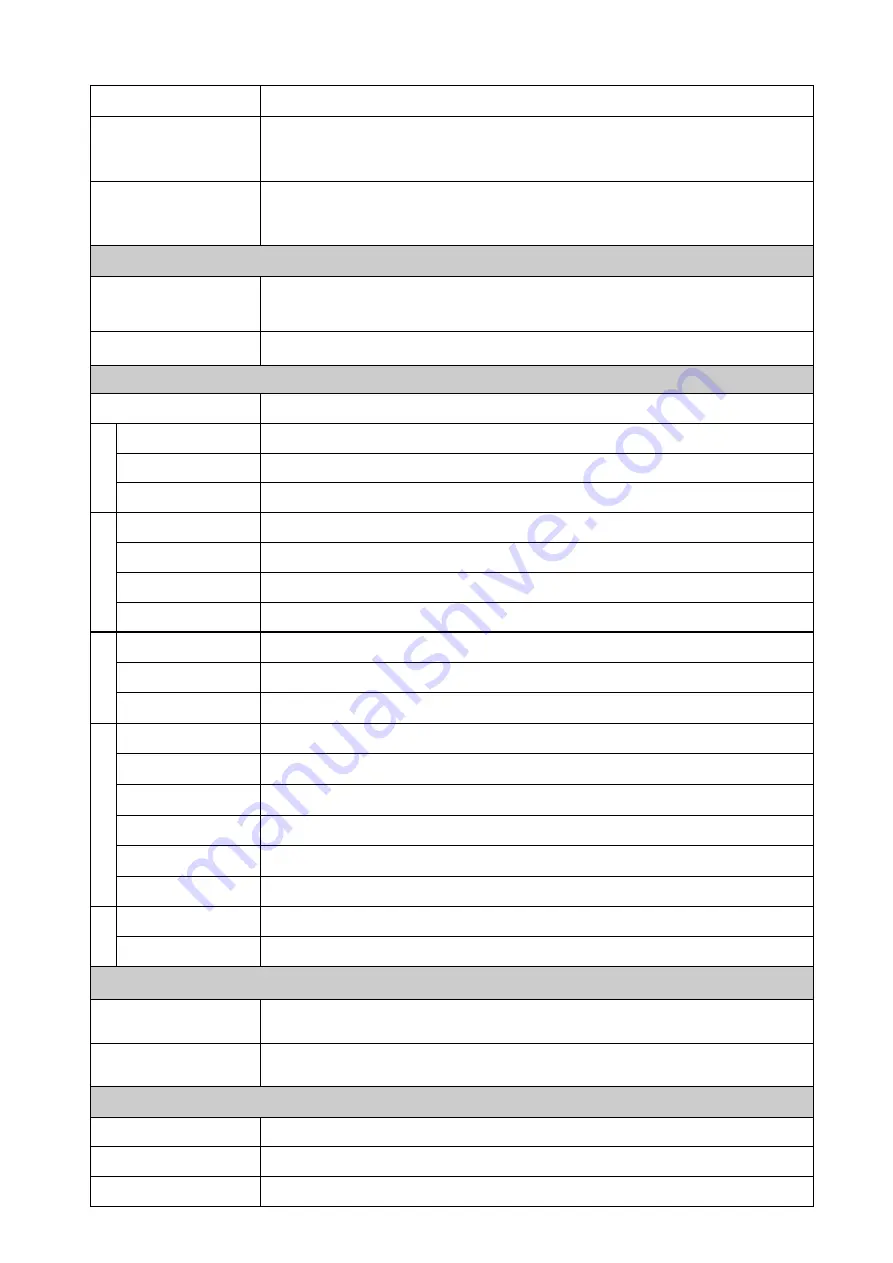

Baud rate

1200 to 57600 programmable

Data

Length 7 or 8 bits; parity even, odd or none

Stations

Up to10 stations

E

the

rne

t TC

P

/I

P

Transmission rate

10 / 100 Mbit/s, Full duplex

TCP/IP settings

Manual IP assign over Indface2x PC Software or by keys in programming mode.

Connection method Server or Client

Installation

Switched Ethernet transmission with shielded twisted pair cables and RJ-45.

Isolation

Galvanically isolated bus electronics

Response speed

Up to 4 ms response delay after read/write commands

US

B

Connection

Standard USB Micro-B cable

Response speed

Min. 4 ms response delay after read/write commands

Digital Inputs and Outputs (optional)

Digital Inputs

Optoisolated 4 digital input, 12 to 28 VDC, 10mA.

Any input(s) can be used as a Remote input of your PLC over BSI or Modbus.

Digital Outputs

5 free relay contact, 250 VAC or 30 VDC, 0.2A

Any output(s) can be used as a Remote output of your PLC over BSI or Modbus.

Analogue Output (opional)

Voltage output

0-5 VDC, 0-10 VDC

Current output

4-20mA, 0-20mA

Resolution

60 000 steps

Dynamic filter

Programmable dynamic filter

Weighing functions

Taring, zeroing, auto zero tracking, motion detection, auto zero at power up, tare

status saves at power off, increased resolution, automatic tare and clear,

temporary gross indication, unit change.

Standard applications

Labelling with barcode, checkweighing, classifying, basic filling, peak holding,

totalization, livestock weighing and free setpoints, functional outputs,

Remote IO of PLC or HMI, fieldbus interface.

Memory

Application memories

ID1, ID2, Limit values for weighing of items / setpoint memory and preset tare

memory.

Each memory size is 500 item records.

Alibi memory (optional) 99 999 records

Communication

Connectable with

PC, PLC, Printer, Remote display, EPL printer etc.

RS

2

32

Isolation

Galvanically isolated.

Baud rate

1200 to 57600 programmable

Data

Length 7 or 8 bits; parity even, odd or none

RS

4

85

Isolation

Galvanically isolated.

Baud rate

1200 to 57600 programmable

Data

Length 7 or 8 bits; parity even, odd or none

Stations

Up to 31 stations