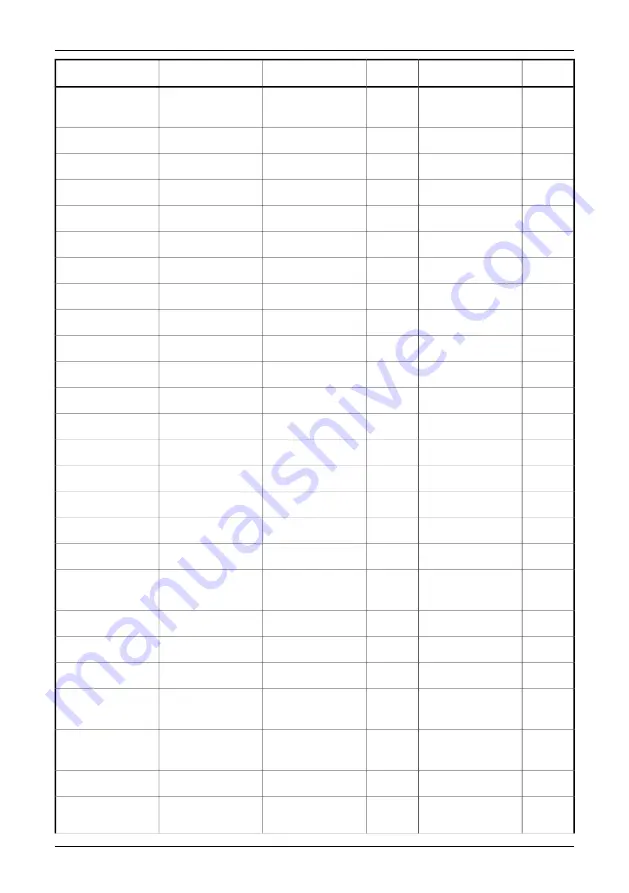

6

5

4

3

2

1

9

0.95–0.97

SW

70

rough, 4 different

samples

Granite

1

0.8–0.9

T

20

Gypsum

Ice: See Water

1

0.81

T

50

casting

Iron, cast

1

0.95

T

1000

ingots

Iron, cast

1

0.28

T

1300

liquid

Iron, cast

1

0.60–0.70

T

800–1000

machined

Iron, cast

4

0.63

T

38

oxidized

Iron, cast

2

0.64

T

100

oxidized

Iron, cast

4

0.66

T

260

oxidized

Iron, cast

4

0.76

T

538

oxidized

Iron, cast

1

0.64–0.78

T

200–600

oxidized at 600°C

Iron, cast

4

0.21

T

38

polished

Iron, cast

2

0.21

T

40

polished

Iron, cast

1

0.21

T

200

polished

Iron, cast

1

0.87–0.95

T

900–1100

unworked

Iron, cast

9

0.09

LW

70

cold rolled

Iron and steel

9

0.20

SW

70

cold rolled

Iron and steel

1

0.61–0.85

T

20

covered with red

rust

Iron and steel

4

0.05

T

22

electrolytic

Iron and steel

4

0.05

T

100

electrolytic

Iron and steel

4

0.07

T

260

electrolytic

Iron and steel

1

0.05–0.06

T

175–225

electrolytic, careful-

ly polished

Iron and steel

1

0.24

T

20

freshly worked

with emery

Iron and steel

1

0.55–0.61

T

950–1100

ground sheet

Iron and steel

2

0.69

T

20

heavily rusted

sheet

Iron and steel

158

Publ. No. T559382 Rev. a358 – ENGLISH (EN) – June 23, 2009

24 – Emissivity tables

Summary of Contents for Extech i5

Page 2: ......

Page 3: ...User s manual Publ No T559382 Rev a358 ENGLISH EN June 23 2009 ...

Page 6: ...vi Publ No T559382 Rev a358 ENGLISH EN June 23 2009 ...

Page 179: ......