18

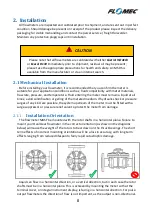

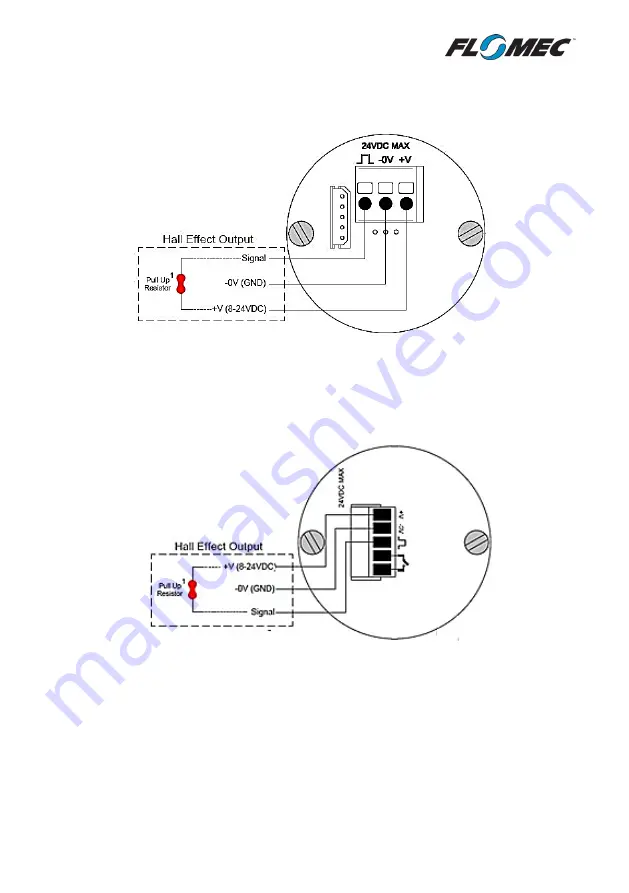

2.4.4

Hall Only Output

Applicable Models: 004 ~ 015 Hall Only, 004 & 006 High Resolution Option

Applicable Models: 025, 040, 050, 080, 080E, 100, 100E

Notes for Connection of Hall Only Pulse Output Boards

1.

Pull up resistor required for operation of Hall Effect output; 10 kΩ is recommended.

See

section 2.2.2 for further information.