8

2.

Installation

All flowmeters are inspected and calibrated prior to shipment, and are sent out in perfect

condition. Should damage be present on receipt of the product please inspect the delivery

packaging for visible mishandling and contact the parcel service / freight forwarder.

Maintain any protective plugs/caps until installation.

2.1

Mechanical Installation

Before installing your flowmeter, it is recommended that you confirm the meter is

suitable for your application conditions such as; fluid compatibility with meter materials,

flow rate, pressure, and temperature. Fluid entering the meter must remain a liquid at all

times; avoid solidification or gelling of the metered medium. If hydraulic shock or pressure

surges of any kind are possible, the system upstream of the meter must be fitted with a

surge suppressor or pressure relief valve to protect the meter from damage.

2.1.1

Installation Orientation

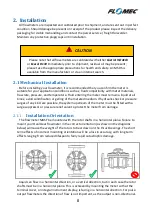

The flowmeter MUST be mounted with the rotor shafts in a horizontal plane. Failure to

mount your Oval Gear flowmeter in the correct orientation

(as shown in the diagrams

below)

will cause the weight of the rotors to bear down on the thrust bearings. The short

term effects of incorrect mounting orientation will be a loss in accuracy, with long term

effects ranging from reduced lifespan to fairly rapid catastrophic damage.

Liquid can flow in a horizontal direction, or a vertical direction, but in each case the rotor

shafts must be in a horizontal plane. This is achieved by mounting the meter so that the

terminal cover, or integral instrument display, is facing in a horizontal direction. For pulse

output flowmeters the direction of flow is not important, as the output is non-directional.

Please note that all flow-meters are calibrated with either

Castrol ISO4113

or

Exxsol D130

immediately prior to shipment, residual oil may be present;

please take the appropriate precautions for health and safety. An MSDS is

available from the manufacturer or via an internet search.

CAUTION