-

2

-

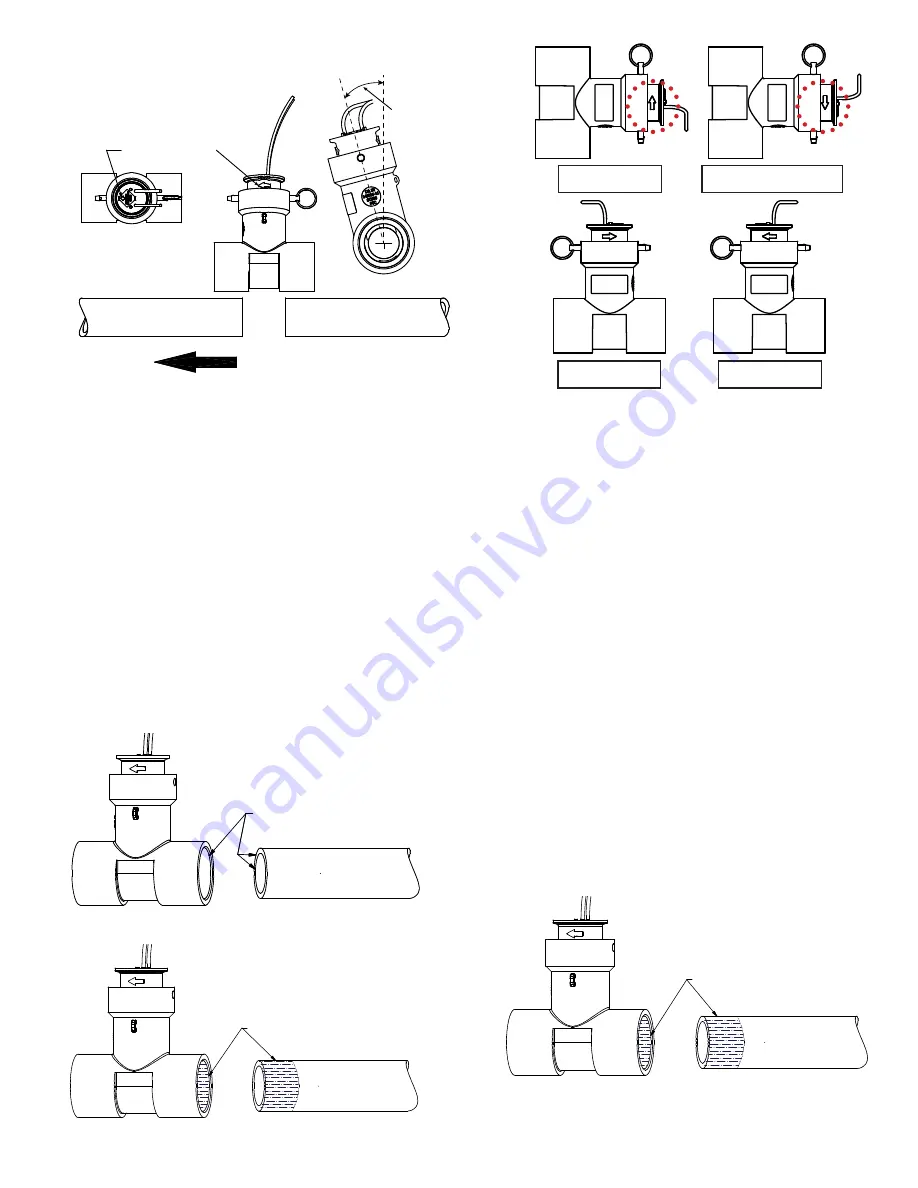

Figure 1a

Figure 1b

Figure 2

Figure 3

Figure 4

FLOW DIRECTION

10Xs

5Xs

DOWNSTREAM

UPSTREAM

INSTALL AT

ANGLE, IF

POSSIBLE

PAGE 8

INSERT

TOP VIEW

FLOW DIRECTION

ARROW

GENERAL INSTALLATION PROCEDURE (continued)

TEE INSTALLATION (FLOMEC TEE ONLY)

NOTE:

It is recommended to install Tee at an angle. The water lines are not supposed to have air in them, however,

sometimes very minute pockets of air can get trapped in the QS200. Installing at an angle helps reduce the consequences

of this issue.

IMPORTANT:

The 1 inch line size FLOMEC

®

Tee should be installed at a 45 degree angle.

1. Remove all burrs from inner and outer diameter

of PVC pipe that will be connected to the FLOMEC

Tee. Also, remove inner diameter burrs from

FLOMEC Tee (See Figure 2).

-

NOTE:

Installation drawings show the QS200 insert

in the Tee, but it is recommended to install the Tee

first without the QS200 insert inside. This will keep

excess PVC cement off of the QS200 insert.

2. Clean and apply Primer to pipe ends and tee

sockets (See Figure 3).

3. Apply PVC cement to pipe ends and Tee sockets

and quickly assemble the parts while the cement

is fluid. Follow the cement manufacturer’s

instructions (See Figure 4).

-

NOTE:

Only use PVC cement – Do not try other PVC

alternatives.

-

NOTE:

Make sure Tee is tilted at required angle for

QS200 (1 inch pipe installations will need a larger

45 degree angle tilt).

4. Hold the cemented parts together for a minimum

of 30 seconds.

Below ground installations should be installed with a valve

box with a minimum of 10 inches thick (deep) layer of

gravel directly underneath the QS200. The gravel shall be

through the entire length and width of the valve box. Valve

box extensions may be needed depending on depth.

APPLY PRIMER

APPLY CEMENT

REMOVE BURRS

CORRECT

CORRECT

NOT CORRECT

CORRECT