Meteor 250 MkII

FLOOREX- 1800

14

.

1800 356 673

Problem solving

Diamond Grinding has many variables. When you understand some of these, you

can solve many problems without a lot of bother and expense.

PROBLEM

CAUSE

REMEDY

WHAT IS IT DOING?

Machine will not

start / run.

No power is present at

cable end.

Check the power is present

with another tool.

Using another tool confirms

power is present

Machine is trying to start

on glue or other sticky

substance.

Clear a patch with a scraper

and grind into the glue a little

at a time.

This means it only tackles a

small amount of glue at a

time and keeps the glue

residue coated with dust,

preventing glue build-up on

the diamonds.

Power lead is too small in

capacity or too long.

Upgrade the power lead to

2.5mm² (20 meters) max or

4mm² (50 meters max).

The long / small capacity

cable is too restrictive and

can’t allow enough power

through for the machine to

start / run properly.

Machine is not

grinding at all.

No blade / accessories in

unit.

Fit blade

. Note; check wear on

machine.

Very hard concrete or

glazed topping on

concrete.

Turn dust extractor down /

restrict flow. Only just control

the dust from escaping.

The extra dust accumulating

on the floor acts as an

abrasive between the

segments and the floor thus

exposing the diamonds

better.

Place river sand or equivalent

on the floor.

The sand is an abrasive as

described above.

Use softer grade of diamond

tooling.

The softer grade will expose

the diamonds better.

Use coarser diamond tooling. The coarser diamond tooling

can get through the hard

topping without wearing out

the diamonds too fast.

The diamonds

are wearing out

too fast.

The concrete is:

*Soft

*Abrasive

*Rain Damaged

*A rough finish

(Scarified).

Use a powerful dust extractor

to remove as much dust as

possible.

The dust, as described acts

as an abrasive between the

segments exposing the

diamonds prematurely,

wasting them.

Use harder diamond matrix.

The harder segments don’t

expose as easily.

Use tooling with more

segments or area² of

segment.

The tooling with more

segments or area² doesn’t

have the same weight on

them, reducing wear.

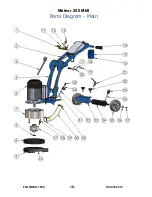

Summary of Contents for Meteor 250 MkII

Page 11: ...Meteor 250 MkII FLOOREX 1800 10 1800 356 673 Axle height adjustment ...

Page 12: ...Meteor 250 MkII 1800 356 673 11 1800 FLOOREX Axle height adjustment ...

Page 13: ...Meteor 250 MkII FLOOREX 1800 12 1800 356 673 Axle height adjustment ...

Page 19: ...Meteor 250 MkII FLOOREX 1800 18 1800 356 673 Parts Diagram Main ...

Page 22: ...Meteor 250 MkII 1800 356 673 21 1800 FLOOREX Parts Diagram Old Coupling for older models only ...

Page 25: ...Meteor 250 MkII FLOOREX 1800 24 1800 356 673 Parts Diagram Lafert motor If Fitted ...

Page 26: ...Meteor 250 MkII 1800 356 673 25 1800 FLOOREX Wiring Diagram ...

Page 27: ...Meteor 250 MkII FLOOREX 1800 26 1800 356 673 ...