GB

GB

14

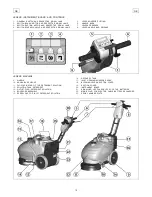

LEGEND INSTRUMENT BOARD AND CONTROLS

1.

GENERAL SWITCH AND RESPECTIVE SIGNAL LAMP

2.

SWITCH BRUSH MOTOR AND RESPECTIVE SIGNAL LAMP

3.

SWITCH SUCTION MOTOR AND RESPECTIVE SIGNAL LAMP

4.

SWITCH SOLENOID VALVE AND RESPECTIVE SIGNAL LAMP

5.

LEVER SQUEEGEE LIFTING

6.

HANDLE BARS

7.

LEVERS PRESENCE

8.

LEVER HANDLE BAR RELEASE

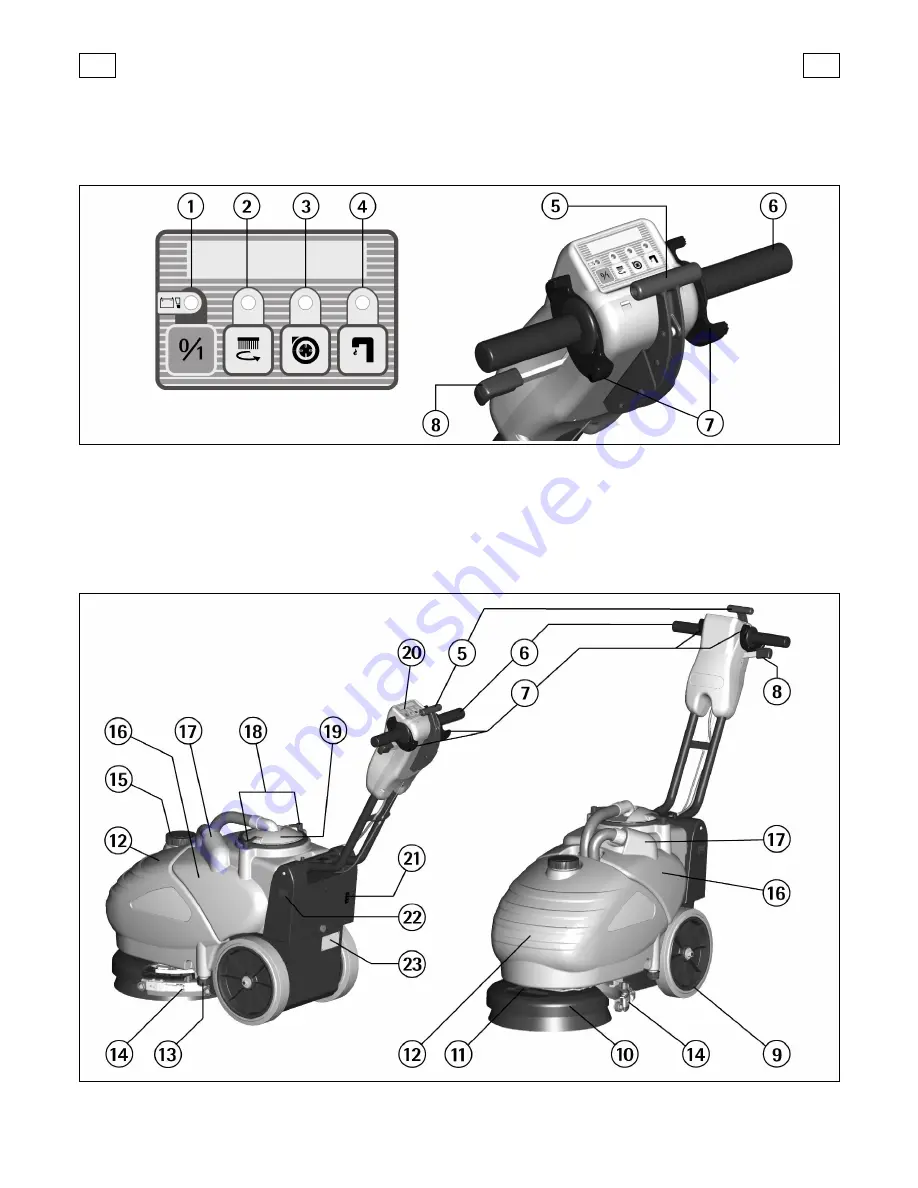

LEGEND MACHINE

9.

WHEELS

10.

BRUSH BASE GROUP

11.

FLOW ADJUSTER OF THE DETERGENT SOLUTION

12.

SOLUTION TANK DETERGENT

13.

OUTLET PLUG DETERGENT SOLUTION

14.

SQUEEGEE ASSEMBLY

15.

SCREW CAP FOR INLET DETERGENT SOLUTION

16.

RECOVERY TANK

17.

INLET OPENING SQUEEGEE HOSE

18.

BLOCKING LEVERS SUCTION COVER

19.

SUCTION COVER

20.

INSTRUMENT BOARD

21.

SIGNALLING LED CHARGE LEVEL OF THE BATTERIES

22.

MAINS PLUG FOR ELECTRIC CABLE BATTERY RECHARGER

23.

SERIAL NUMBER PLATE