GB

GB

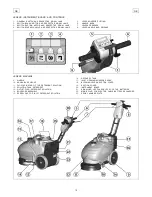

18

NOTE: Never leave batteries completely

discharged even if the machine is not used.

Connect the mains cable supplied with the

machine both to the machine and to the mains

socket as indicated in the figure.

Insert the plug into a single-phase socket type

CEE 7/7, with tension 230V, frequency 50Hz,

nominal current 10A.

ATTENTION:

Never charge batteries with a non suitable

recharger. Strictly follow the instructions

supplied by the batteries and recharger

manufacturer.

BATTERIES DISPOSAL

It is compulsory to hand over exhaust batteries,

classified as dangerous waste, to an authorized

institution according to the current laws.

RECOVERY TANK

Check that the cover of the suction filter (19)

is correctly secured, after rotating the levers

(18). Furthermore, check that the squeegee

hose is correctly seated in its seat (17).

DETERGENT SOLUTION TANK

The capacity of the detergent solution tank is

indicated in the technical data.

Open the screw plug (1) placed in the rear

left part of the machine and fill the detergent

solution tank with clean water at a maximum

temperature of 50°C. Add the liquid detergent

in the percentage and conditions foreseen by

the manufacturer. To avoid excessive foam

presence, which could cause problems to the

suction motor, use the minimum percentage of

detergent. Screw down the plug to close the

tank.

ATTENTION:

Use always low foam detergent. To avoid foam

presence, before starting working operation,

introduce into the recovery tank a minimum

quantity of anti-foam product.

Never use pure acid.

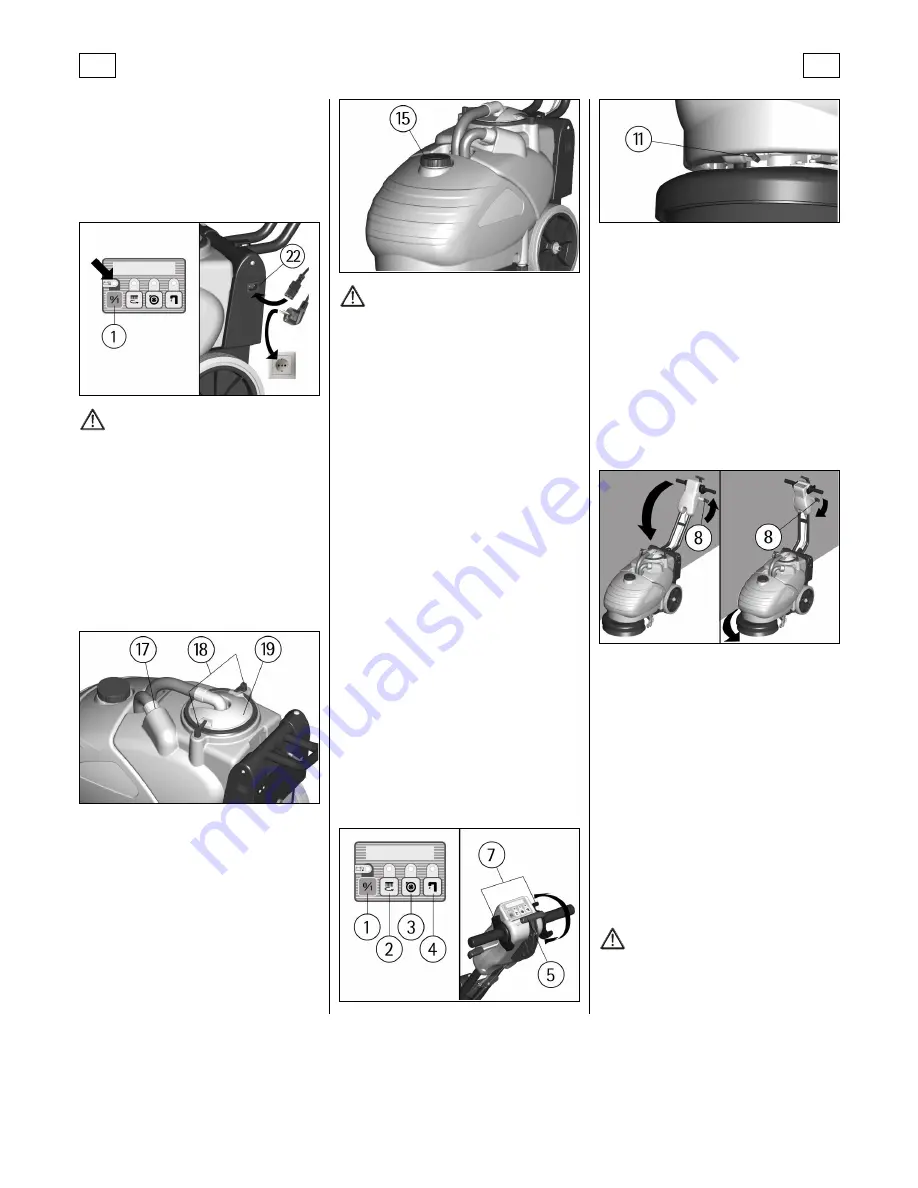

FLOOR CLEANING

STARTING OF THE MACHINE

The push buttons on the instrument board are

equipped with an upper green signal light that

signal the activation of the control.

1. Switch on the machine pressing the general

switch (1).

2. Check the battery charge level (see under

“BATTERIES RECHARGING”).

3. Lower the squeegee rotating to the lower

part the handle lever (5) placed in the

centre of the handle bar.

4. Press the switch of the brush motor (2).

5. Press the switch of the suction motor (3).

6. Press the switch of the solenoid valve (4).

The machine is equipped with solenoid valve,

therfore the detergent solution flow will be

activated automatically acting upon the levers

movement (7). Releasing these levers, flow

will stop automatically.

7. Activating the levers (7) the brush will

start rotating. The detergent solution flow

begins to run and the squeegee will start

drying the floor.

9. During the first meters check that the

detergent solution flow is appropriate. The flow

adjuster of the detergent solution is already

adjusted inthe factory to satisfy the cleaning of

most floors. If it is necessary to modify the

quantity of detergent solution onto the floor,

act upon the lever of the flow adjuster (11).

9. Moving the machine backwards, make sure

that the squeegee is lifted.

HANDLE BAR ADJUSTMENT

When arriving close to obstacles or near walls,

it is possible to simplify the manoeuvre of the

machine adjusting the handle bar more

vertically with respect to the machine.

To rotate the handle bar:

1. Act upon the release lever (8) present

near the handle bar.

2. Rotate the handle bar into the new working

position keeping the release lever (8) pressed.

3. Release the lever (8) to obtain the handle

bar blocking.

Once the obstacle has been passed and the

manoeuvre completed repeat the operation to

return to the previous working position.

This operation is possible also with the

machine in movement maintaining pressed

contemporarily the handle bar levers (7).

OVERFLOW DEVICE

In order to avoid serious damages to the

suction motor, the machine is equipped with a

float that intervenes when the recovery tank is

full, closing the suction hose and stopping the

suction.

When this happens, it is necessary to empty

the recovery tank.

1. Switch off the machine pressing the general

switch.

2. Take off the suction filter cover (19) after

turning the blocking levers (18).

3. Take off the squeegee hose from its seat

(17).

4. Lift and take off the recovery tank (16)

holding it from the provided handles obtained

one behind and the other in front of the tank.

Empty the recovery tank into appropriate

containers, according to the standard norms for

the liquid disposal.

5. Reassemble everything.

ATTENTION:

This operation must be carried out using

gloves to protect from contact with dangerous

solutions.