GB

GB

19

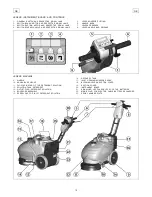

SECURITY DEVICE BRUSH LIFTING

A security device blocks the brush motor when

for any reason the brush is being lifted from

the floor during operation. This condition may

be determined exercising a strong pressure on

the handle bar so that a rotation of the

machine is obtained on the wheels and then

the consequent brush lifting from the floor.

The presence of this device impedisce any

possible risk as in this condition the brush

stops.

The return to the normal working position and

therefore with the brush poggiata to the floor

re-establishes immediately its normal functioning.

STOP OF THE MACHINE AFTER

CLEANING OPERATION

Before carrying out any type of maintenance:

1. Switch off the general switch (1).

2. Lift the squeegee rotating upwards the lever

(5) placed in the centre of the handle bar.

3. Bring the machine to an appropriate place

for tanks draining.

ATTENTION:

The machine is not equipped with a parking

brake, therefore do not leave it on slopes.

DAILY MAINTENANCE

EMPTYING AND CLEANING OF THE

RECOVERY TANK

To empty and clean the recovery tank.

1. Switch off the machine pressing the general

switch.

2. Take off the suction cover (19) after

rotating the blocking levers (18).

3. Take off the squeegee hose from the seat

(17).

4. Lift and take off the recovery tank (16)

holding it from the provided handles obtained

one behind and the other in front of the tank.

Empty the recovery tank into appropriate

containers, according to the standard norms for

the liquid disposal.

5. Provide for the rinsing and cleaning of the

tank.

6. Reassemble everything.

ATTENTION:

This operation must be carried out using

gloves to protect from contact with dangerous

solutions.

EMPTYING AND CLEANING OF THE

DETERGENT SOLUTION TANK

To empty the detergent solution remained in

the solution tank:

1. Bring the machine to an appropriate place

for tanks draining.

2. Switch off the machine pressing the general

switch.

3. Unscrew the loading plug (15) of the

solution tank.

4. Unscrew the exhaust plug (13) placed in

the rear low left part of the machine.

ATTENTION:

This operation must be carried out using

gloves to protect from contact with dangerous

solutions.

SUCTION FILTER CLEANING

1. Take off the suction cover (19) after

rotating the blocking levers (18).

2. Take off the filter with the float bending the

filter edge to release it from the screws

present on the cover.

3. Clean all parts with a water jet and

especially the surfaces and filter bottom.

4. Carry out carefully the cleaning operations.

5. Reassemble everything.

POSITIONING OF THE MACHINE FOR

MAINTENANCE AND PARKING

The machine can assume a vertical positioning

tipped over at the back after having refolded

the handle bar onto the machine.

This position permits a minor space occupied

for the machine parking and simplifies its

maintenace operations.

To rotate the machine it is necessary to:

1. Switch off the general switch.

2. Check that both tanks are empty, otherwise

provide

to

empty

them

(see

under

“EMPTYING AND CLEANING OF THE

RECOVERY TANK” and “EMPTYING AND

CLEANING OF THE SOLUTION TANK”).

3. Act upon the release lever (8) present

near the handle bar.

4. Rotate the handle bar towards the tanks

keeping the release lever (8) pressed.

5. Release the lever (8) to obtain the handle

bar blocking.