GB

GB

19

When this happens, it is necessary to take off the

plug from the mains socket and to empty the re-

covery tank.

1. Hold the exhaust hose placed in the front part

of the machine.

2. Take off the exhaust plug acting upon its

lever and empty the recovery tank into appropri-

ate containers, according to the standard norms.

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions

EMPTYING DETERGENT SOLUTION

To empty the detergent solution remained in the

solution tank:

1. Bring the machine to an appropriate place for

tanks draining.

2. Unscrew the exhaust plug (1).

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions.

EMPTYING DEVICE DETERGENT SOLUTION (OP-

TIONAL)

To recover the detergent solution, it is necessary

to use the emptying device provided for the

purpose and proceed as follows:

1. Unhook the hose.

2. Open the solution valve directing the jet into

a collecting container.

3. When the operation has been completed,

close the solution valve.

Put the hose back into its position, placing it into

the spring.

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions.

FORWARD MOVEMENT

The traction of these machines is given by the

brushes that, working on an inclined axle, trans-

mit to the machine the forward movement. The

effect is bigger with brushes that have thicker

bristles.

STOP

Releasing the lever of the presence, brushes rota-

tion will end, stopping the machine movement.

ATTENTION:

Moving the machine backwards, make sure that

the squeegee is lifted.

ADJUSTMENT OF BRUSHES INCLINATION (OP-

TIONAL ruby45e, ruby55e)

Through the register (1) placed on the brushes

base group, it is possible to adjust the brushes

inclination increasing/decreasing the speed of

the machine. A label placed on the brushes base

indicates the adjustment levels LOW/FAST.

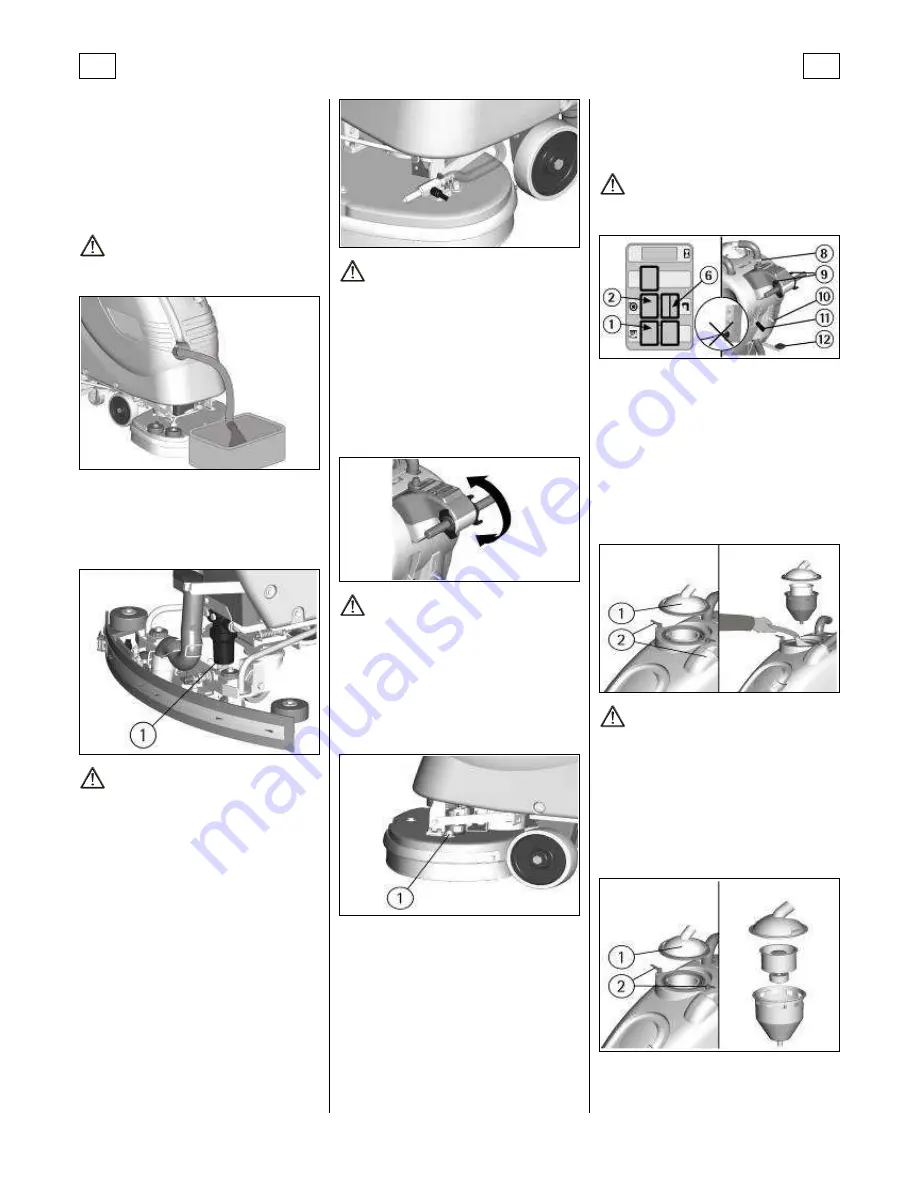

STOP OF THE MACHINE AFTER

CLEANING OPERATION

Before executing any type of maintenance:

1. Close the solution valve through the lever (10).

2. For machines optionally equipped with sole-

noid valve (see under "OPTIONAL ACCESSORIES")

the flow of detergent solution will stop auto-

matically when the levers (9) are released. On the

instrument board the signal lamp of the open so-

lution valve will go off (6).

3. Lift the brushes base acting upon the pedal

(12).

4. Lift the squeegee acting upon the lever (11).

5. Turn the brushes motor switch off (1).

6. Turn the suction motor switch off (2).

7. Take off the plug from the mains socket.

8. Bring the machine to an appropriate place for

tanks draining.

ATTENTION:

The machine is not equipped with a parking

brake, therefore do not leave it on slopes.

DAILY MAINTENANCE

RECOVERY TANK CLEANING

1. Hold the exhaust hose placed in the front part

of the machine.

2. Take off the exhaust plug acting upon its

lever and empty the recovery tank into appropri-

ate containers (see under "OVERFLOW DEVICE").

3. Take off the suction cover (1) after rotating

the blocking levers (2).

4. Take off the filter and filter protection.

5. Rinse the tank with a water jet.

ATTENTION:

This operation must be carried out using gloves

to protect from contact with dangerous solutions.

SUCTION FILTER CLEANING

1. Take off the suction cover (1) after rotating

the blocking levers (2).

2. Take off the filter and filter protection.

3. Clean all parts with a water jet especially in-

side surfaces and filter bottom.

4. Carry out carefully the cleaning operations.

5. Reassemble all parts.

BRUSHES CLEANING

Disassemble the brushes and clean them with a

water jet (for the brushes disassembly, check

“BRUSHES DISASSEMBLY” paragraph).