FLORIDA-PNEUMATIC.COM

Please contact 1-800-356-3392 for further assistance.

Safety Information (continued)

AIR COMPRESSOR AND AIR TOOL SAFETY

1. Risk of Bursting. Do not adjust the regulator to result in output

pressure greater than the marked maximum pressure of this air

tool.

2. Ensure the hose is free of obstructions or snags. Entangled or

snarled hoses can cause loss of balance or footing and may

become damaged.

3. Never leave a tool unattended with the air hose attached.

4. Do not operate this tool if it does not contain a legible warning

label.

5. Do not continue to use a tool or hose that leaks air or does not

function properly.

6. Never direct a jet of compressed air toward people or animals.

7. Protect your lungs. Wear a face or dust mask if the operation is

dusty.

WARNING:

Some dust created by power sanding, sawing,

grinding, drilling and other construction activities contains

chemicals known to cause cancer, birth defects or other

reproductive harm. Some examples of these chemicals are:

Lead from lead based paint, crystalline silica from bricks

and cement and other masonry products, arsenic and

chromium from chemically-treated lumber.

Your risk from those exposures varies, depending on how

often you do this type of work. To reduce your exposure to

these chemicals: work in a well-ventilated area, and work

with approved safety equipment, such as dust masks that

are specifically designed to filter out microscopic particles.

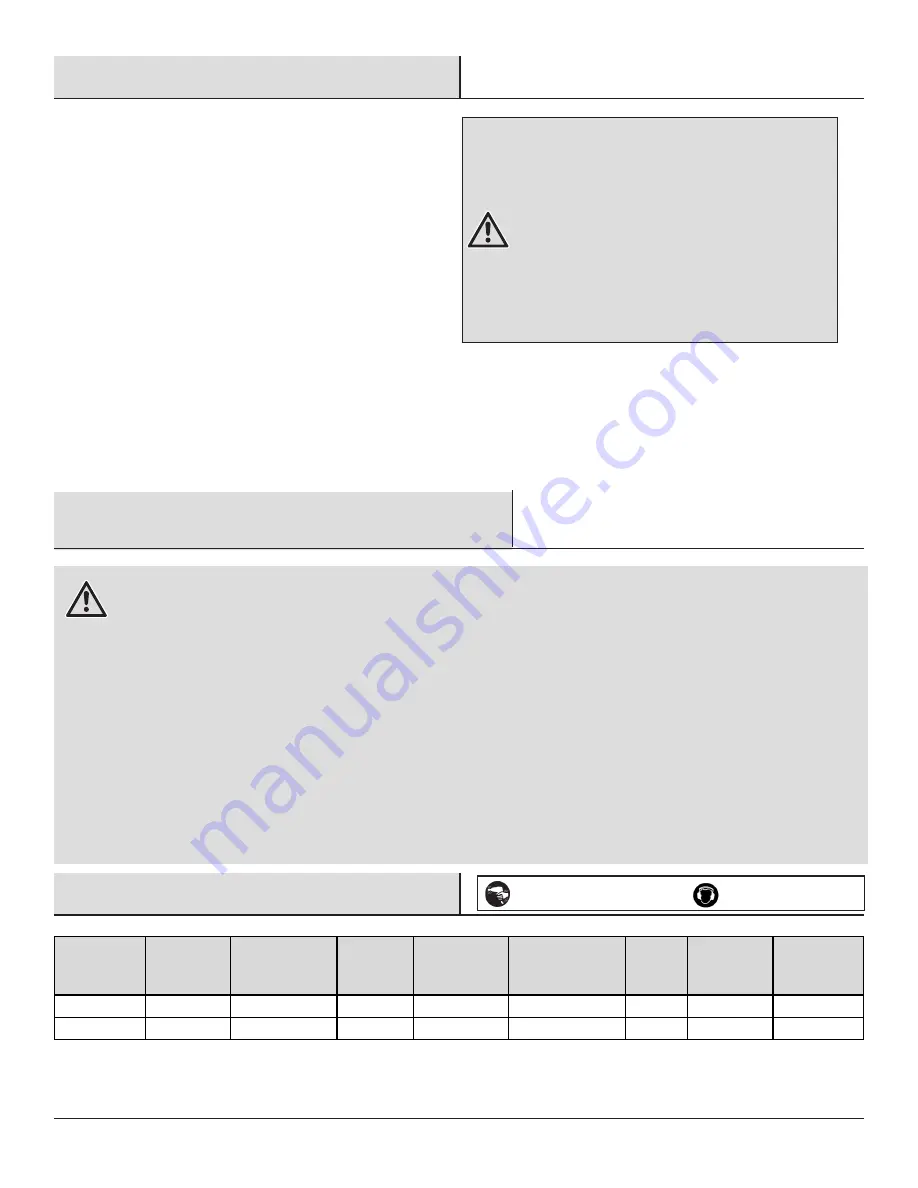

Important Warnings - Impacts

Specifications

1. Eye protection and hearing protection and safety gloves must always be worn when operating an impact wrench or impact

driver.

2. When using heavy impact sockets or sockets on impact wrenches with 3/4” drive anvils or larger, a socket retaining ring

and pin should be used to prevent the socket falling off and causing injury.

3. Use only impact sockets and accessories. Only use sockets designated “FOR USE WITH IMPACT WRENCHES”, hand tool

sockets can break, creating a hazard from flying pieces. Always check sockets, retainers and drives regularly for wear or

damage and replace when necessary.

Accessory Hazards

4. Disconnect the assembly power tool for threaded fasteners from the energy supply before changing the inserted tool or

accessory.

5. Do not touch sockets or accessories during impacting as this increases the risk of cuts, burns or vibration injuries.

6. Use only sizes and types of accessories and consumables that are recommended by the assembly power tool for threaded

fasteners manufacturer; do not use other types or sizes of accessories and consumables.

Vibration Level (m/sec2): 10.7

Noise Level (dBA): 97

Model

Free

Speed

Bolt

Square

Impacts

Max, Torque

Weight

Length

Air Cons

Number

(RPM)

Capacity

Drive

Per Min.

ft/lbs @ 90 psi

(lbs)

(In.)

(CFM)

UT8150P-2

9500

9/16"

1/2"

1, 600

725

5.75

7-1/4

8

UT8150R-2

9500

9/16"

1/2"

1, 600

725

5.75

7-1/4

8