Discharge Pipe and Pressure Tank Connections / Electrical 6

For parts or assistance, call Flotec Customer Service at

1-800-365-6832

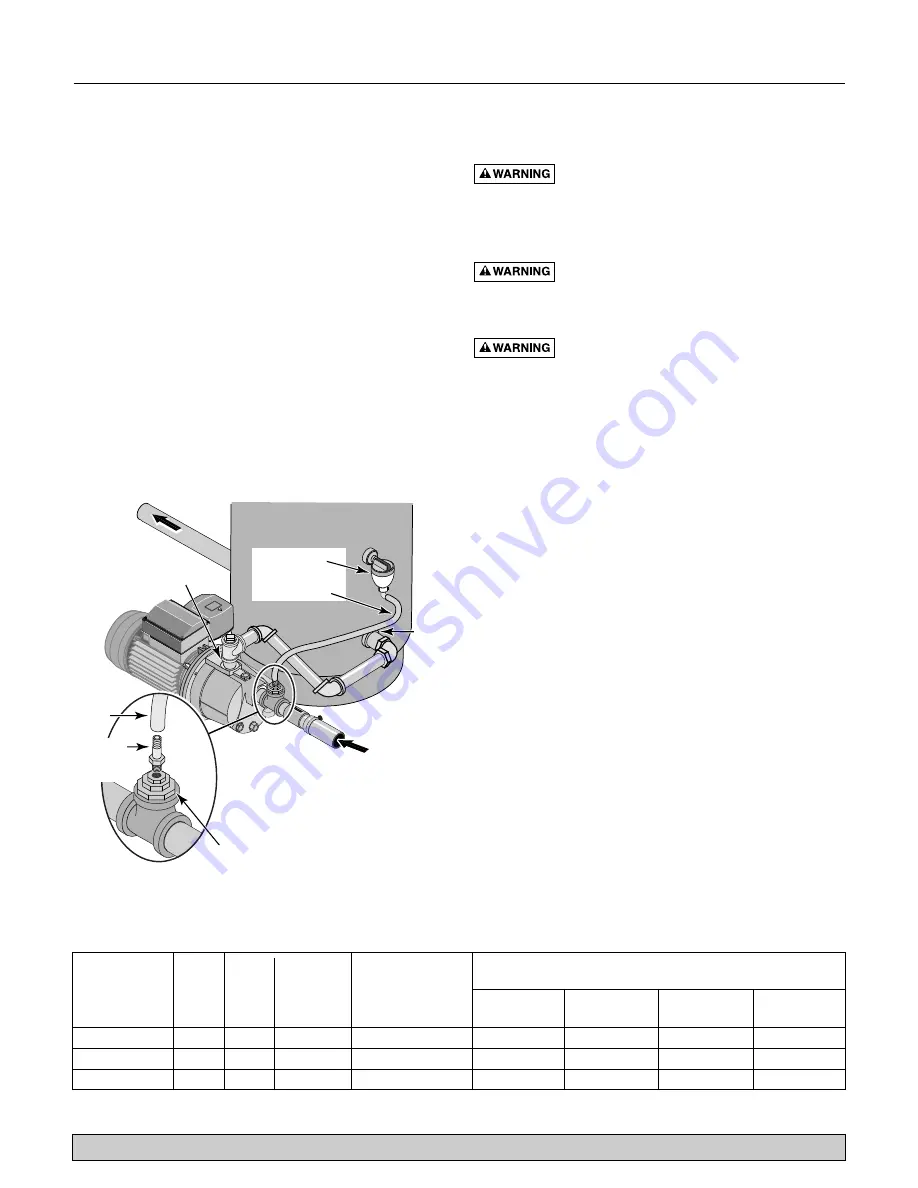

STANDARD TANK CONNECTION

(FIGURE 6)

1. Install a tee in the pump discharge port (see Figure 6).

2. Run a pipe from the pump discharge port to the inlet

port of your tank. The pipe size must be at least as

large as the discharge port.

3. Install a tee with reducing bushings in the suction

pipe as shown in Figure 6.

4. Install a barbed fitting in the smallest bushing

(1/8" NPT).

5. Run the AVC tubing from the barbed fitting on the suc-

tion pipe tee to the port in the AVC mounted on the

tank. See the instructions provided with the tank and

the AVC for details. The AVC port location may vary.

Congratulations! You have just completed the tank con-

nection for your jet pump.

ELECTRICAL

Hazardous voltage. Can shock, burn, or kill.

Connect ground wire before connecting power supply

wires. Use the wire size (including the ground wire) spec-

ified in the wiring chart.

If possible, connect the pump to

a separate branch circuit with no other appliances on it.

Explosion hazard. Do not ground to a gas

supply line.

Wiring

Fire hazard.

Incorrect voltage can cause a

fire or seriously damage the motor and voids the warranty.

The supply voltage must be within ±10% of the motor

nameplate voltage. Do not alter the wiring in the motor.

Connect to 115 Volt supply only.

Install, ground, wire, and maintain your pump in compli-

ance with the National Electrical Code (NEC) or the

Canadian Electrical Code (CEC), as applicable, and with

all local codes and ordinances that apply. Consult your

local building inspector for code information.

Connection Procedure:

Your Pressure Switch looks like one of those shown in

Figure 7. Connect the power supply as shown for your

type of switch.

1. Connect the ground wire first as shown in Figure 7.

The ground wire must be a solid copper wire at least

as large as the power supply wires.

2. There must be a solid metal connection between the

pressure switch and the motor for motor grounding

protection. If the pressure switch is not connected to

the motor, connect the green ground screw in the

switch to the green ground screw under the motor

end cover. Use a solid copper wire at least as large as

the power supply wires.

3. Connect the ground wire to a grounded lead in a ser-

vice panel, to a metal underground water pipe, to a

metal well casing at least ten feet (3M) long, or to a

ground electrode provided by the power company or

the hydro authority.

Distance in Feet (m) from Motor To Supply

Maximum

Branch Wires

Sizes

AWG

(mm

2

)

Load

Circuit Breaker

0-100

101-200

201-300

301-400

Model

HP

Volts

Amps

Rating (Amps)*

(0-30)

(31-61)

(62-91)

(92-122)

FP4105

1/2

115

7.2

15

14 (2)

12 (3)

10 (5.5)

8 (8.4)

FP410515H

1/2

115

7.2

15

14 (2)

12 (3)

10 (5.5)

8 (8.4)

FP4107

3/4

115

8.6

15

14 (2)

10 (5.5)

8 (8.4)

6 (14)

WIRING CHART – RECOMMENDED WIRE AND FUSE SIZES

To Household

Water System

Suction Hose

From Well

Air Volume

Control (AVC)

Tank

Inlet

Port

AVC Tubing

Pump

Discharge

Port

Install a tee in the suction line. Install

reducing bushings down to 1/8" NPT

for the barbed fitting. Install the AVC

tube between the barbed fitting and

the port on the bottom of the AVC

(which is mounted on the tank).

Reducers

AVC

Tube

1/8" NPT

Barbed

Fitting

Figure 6 – Standard Tank Connections

* When using fuses, dual element or Fusetron time delay fuses are recommended for all motor circuits.