www.flowair.com |16

5.4. DOOR CONTACT INSTALLATION

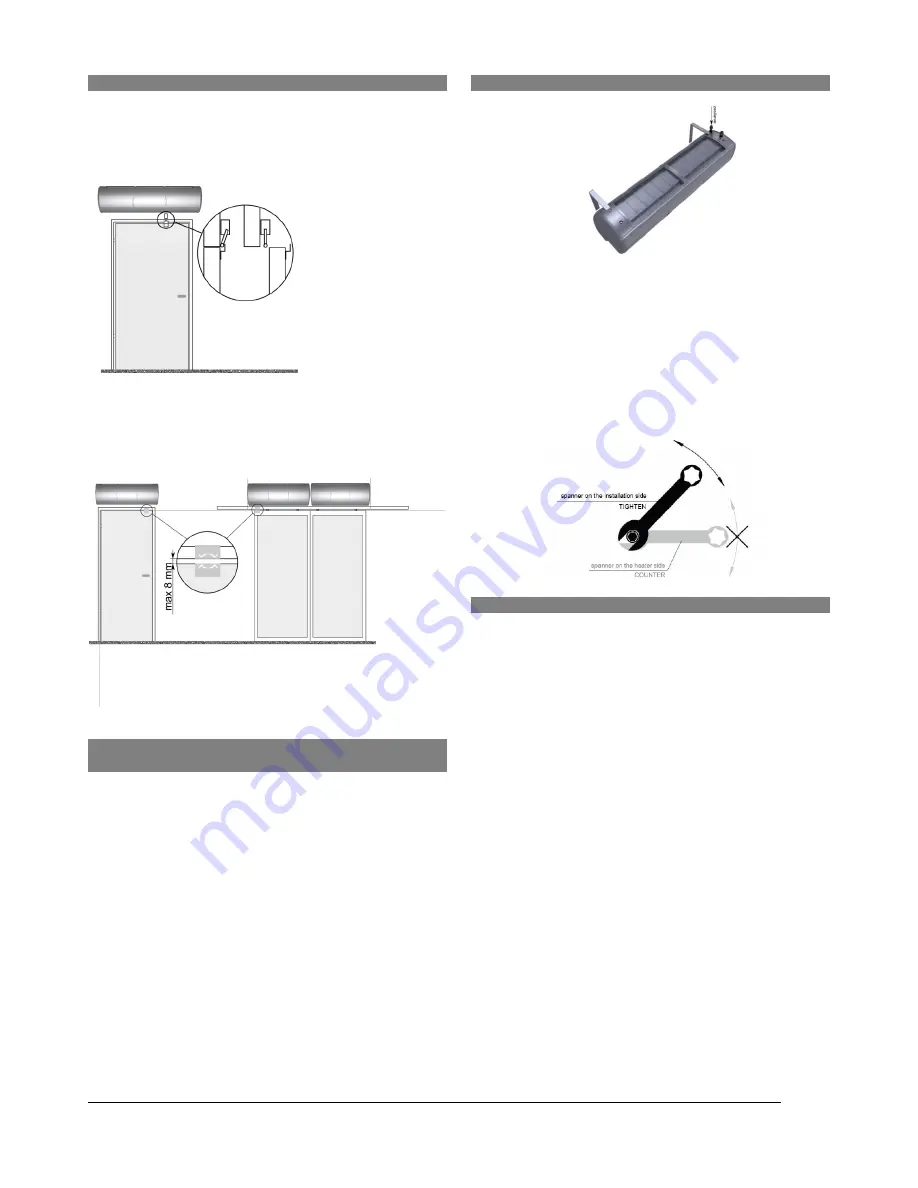

Sample of door contact installation

DCm

– In case of installation in way which is show on drawing

below, connectors 21 and 22 need to be used

Hinged doors

Dce

– In case of installation in way which is show on drawing

below, cable yellow and green need to be used. Other cables

must be isolated.

Hinged door Sliding doors

6. GUIDELINES FOR CONNECTION WITH POWER

SUPPLY

Before connecting the power supply check the correctness of

connection of the fan motor and the controllers. These

connections should be executed in accordance with their

technical documentation.

Before connecting the power supply check whether the

mains voltage is in accordance with the voltage on the device

data shield.

The electrical system supplying the fan motor should be

additionally protected with a circuit breaker against the effects

of a possible short-circuit in the system

Starting the device without connecting the ground conductor

is forbidden.

7. GUIDELINES FOR CONNECTION WITH PIPELINE

The connection should be executed in a way which does

not induce stresses.

It is recommended to install vent valves at the highest point

of the system.

The system should be executed so that, in the case of a

failure, it is possible to disassemble the device. For this

purpose it is best to use shut-off valves just by the device.

The system with the heating medium must be protected

against an increase of the heating medium pressure above

the permissible value (1.6 MPa).

While screwing exchanger to pipeline - connecting stubs

has to be hold by wrench.

8. OPERATION

The device is designed for operation inside buildings, at

temperatures above 0

o

C. In low temperatures (below 0ºC)

there is a danger of freezing of the medium.

The manufacturer bears no responsibility for damage of

the heat exchanger resulting from freezing of the medium

in the exchanger.

It is forbidden to place any objects on the

heater or to hang any objects on the connecting stubs.

The device must be inspected periodically. In the case of

incorrect operation of the device it should be switched off

immediately.

It is forbidden to use a damaged device. The manufacturer

bears no responsibility for damage resulting from the use

of a damaged device.

If it is necessary to clean the exchanger, be careful not to

damage the aluminium lamellas.

For the time of performing inspection or cleaning the

device,

the

electrical

power

supply

should

be

disconnected.

In case water is drained from the device for a longer period

of time, the exchanger tubes should be emptied with

compressed air.