M SLURRY USER

INSTRUCTION ENGLISH 71569241 - 02/08

Page 14 of 60

®

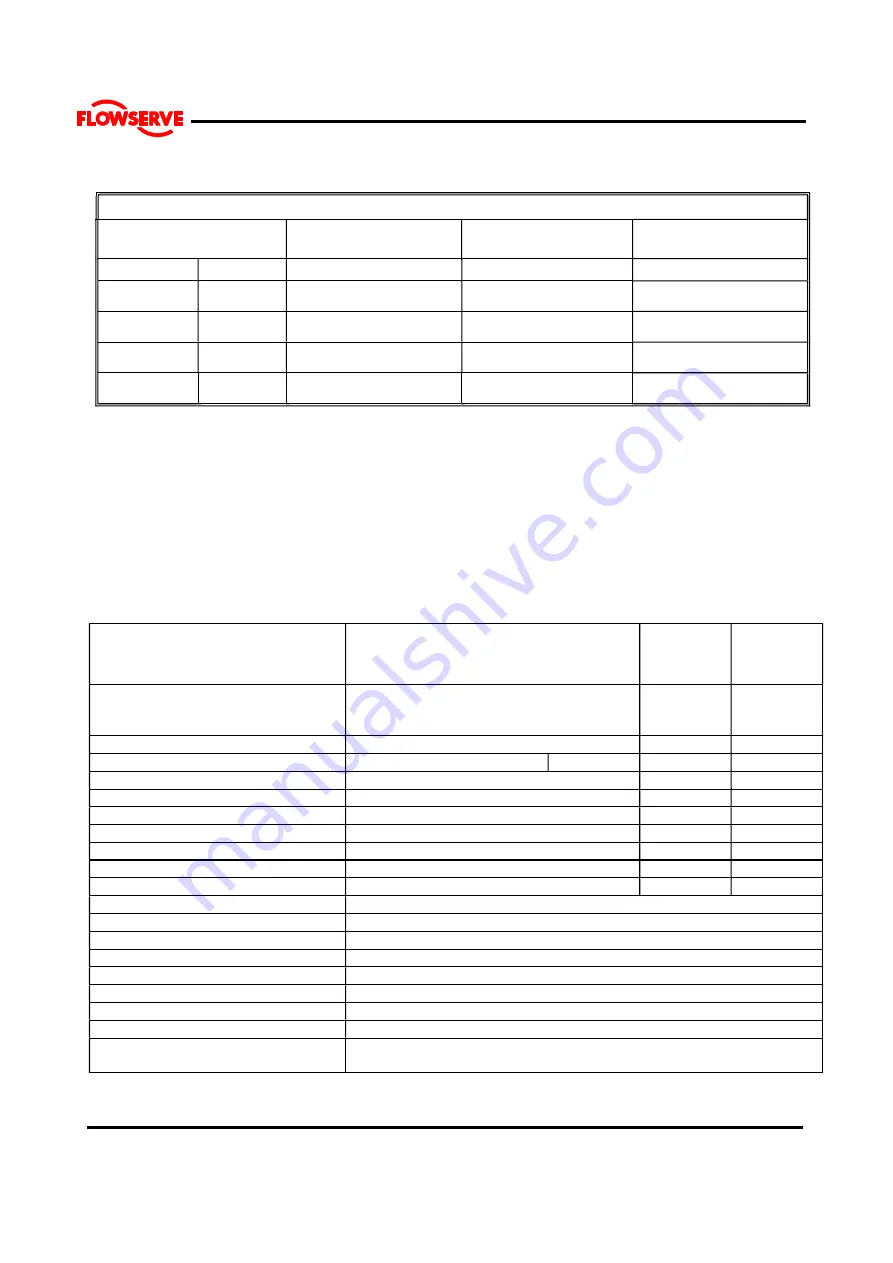

MAXIMUM WORKING PRESSURE

TEMPERATURE

STANDARD DUTY

SEVERE DUTY

Frames 2,3,4 &5

SEVERE DUTY

Frames 6

(ºF)

(ºC.)

Bar (PSIG.)

Bar (PSIG.)

Bar (PSIG.)

-20 TO 100

-7 TO 38

7.6 (110)

10.3 (150)

6.9 (100)

150

65

7.6 (110)

10.3 (150)

6.9 (100)

200

93

6.9 (100)

9.7 (140)

6.6 (95)

250

120

6.2 (90)

9.0 (130)

5.9 (85)

High Chrome Iron is standard for all pumps, special materials are available upon request.

Consult a Flowserve Sales Office or a Distributor for material selection and compatibility with the slurry product.

3.4.3 MAXIMUM WORKING PRESSURES -bar (psi).

3.5 Engineering Data

MATERIALS OF CONSTRUCTION

(LIQUID END)

BASIC

CONSTRUCTION

MATERIAL

CLASS

CASING

IMPELLER

WEAR PLATE

ASTM A532 CL III TYPE A

STUFF BOX HD

ASTM A48 CL35

SUCTION COVER

ASTM A48 CL35

PROTECTOR PLATE

HARD STEEL –360 BHN

IMPELLER SPACER

HARD STEEL –360 BHN

SHAFT SLEEVE

ASTM A743 CG3M *

SHAFT

AISI 1045

GLAND HALVES

ASTM A743 CF8M

PIPE PLUGS (STUFFING BOX)

C.I.

GLAND STUDS AND NUTS

AISI 316

WEAR PLATE STUDS & NUTS

AISI 316

PACKING

SYNTHETIC FIBRE

SEAL CAGE HALVES

ASTM A743 CG8M

GASKETS-CASING

SYNTHETIC FIBRE

GASKETS-SLEEVE

TEFLON

O-RINGS (FRAME END)

BUNA-N ( 120

o

C MAX.)**

MISC. FASTNERS,

PARTS

STEEL