M SLURRY USER

INSTRUCTION ENGLISH 71569241 - 02/08

Page 21 of 60

®

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4,

Products used in

potentially explosive atmospheres.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close as

practicable to the supply of liquid to be pumped.

Allow sufficient room to facilitate the back pull-out

feature on V-belt driven units.

Refer to the general arrangement drawing for the

pump set.

4.2 Part assemblies

Motors may be supplied loose on M Slurry pumps,

typically on frame sizes 400 and above. It is the

responsibility of the installer to ensure that the motor

is assembled to the pump and lined up as detailed in

section 4.5.2.

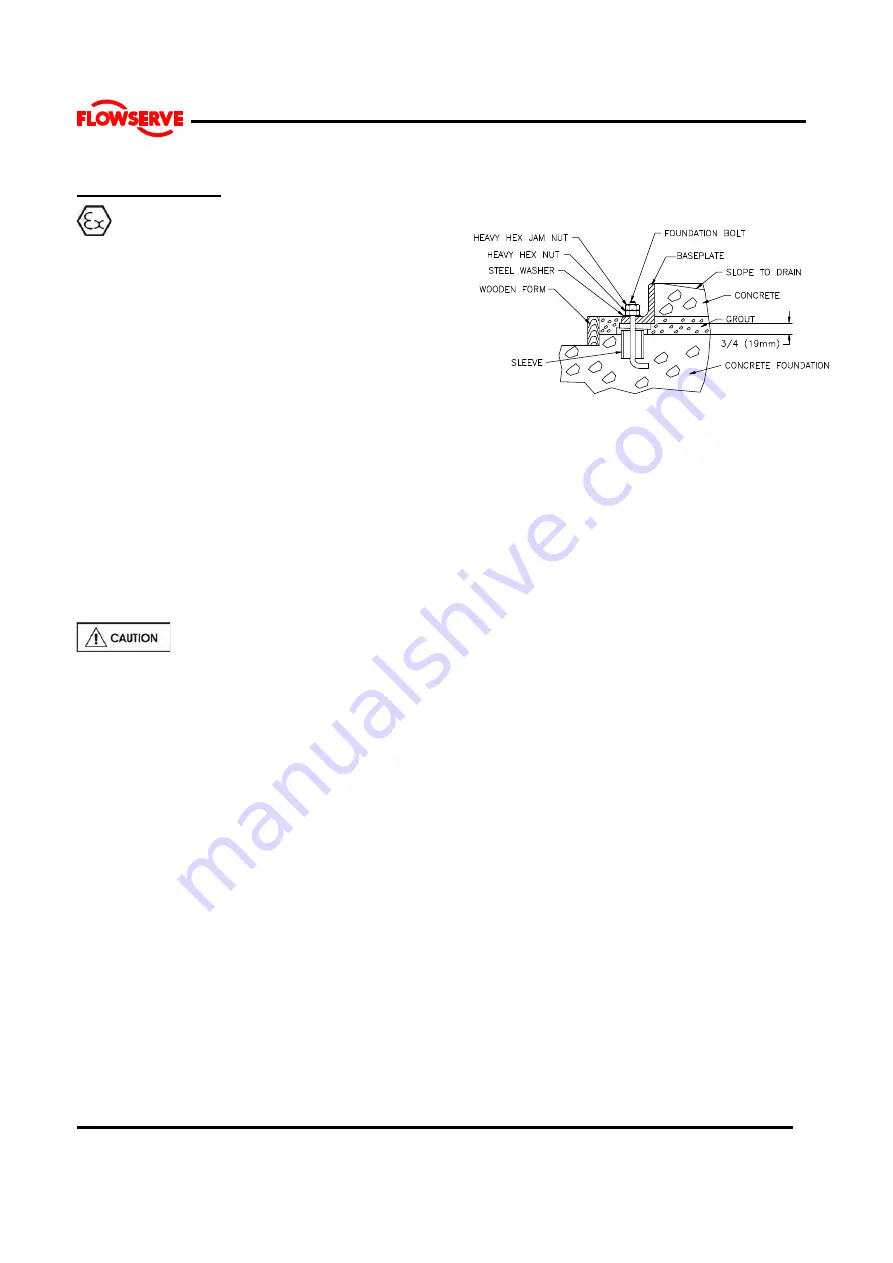

4.3 Foundation

The foundation may consist of any

material that will afford permanent, rigid support to the

full area of the pump or driver supporting member. It

should be of sufficient size and mass to absorb

expected strains and shocks that may be encountered

in service. Concrete foundations built on solid ground

are desirable.

The purpose of foundation bolts is to anchor the pump

unit securely to the foundation such that the foundation

and pump assembly become a single structural unit.

High strength steel foundation bolts (SAE Gr. 5 or

equal) of the specified diameter should be located

according to the elevation drawing provided. Each bolt

should be surrounded by a pipe sleeve that is two or

three times the diameter of the bolt. The sleeves should

be securely anchored and designed to allow the bolts to

be moved to conform with the holes in the baseplate.

The bolts should be sufficiently long to allow for

wedges or shims or levelling nuts under the baseplate,

and a washer, heavy hex nut and hex jam nut for

retention. Since baseplate levelling is performed after

the foundation has cured, it is best to use extra long

bolts that can be shortened after the installation is

complete.

4.4 Baseplate installation

Position the baseplate and pump next to the foundation

and clean the foundation surface thoroughly. Remove

the rag packing from the pipe sleeves and place

wedges or ships as close to the foundation bolts as

possible. These may be omitted if a jacking nut on the

foundation anchor bolts is preferred for levelling. Initial

levelling should be within 0.75 mm (.030 inches).

Remove the flange covers and check inside the pump

nozzles for cleanliness. Kerosene is recommended as

the best solvent for removing factory applied rust

preventative. Ensure that all traces of rust preventative

are removed from the discharge and suction flange

faces, the exposed shafting and all coupling surfaces.

Flush the pump internals of any rust preventative

applied for long-term storage.

Lift the baseplate assembly, remove the shipping skids

and clean the underside of the baseplate. Position the

baseplate over the foundation and lower the unit over

the foundation bolts and onto the wedges, shims or

jacking nuts.

With the aid of a machinist's level, adjust the wedges,

shims or jacking nuts to level the pump and driver

mounting pads in each direction. Check to ensure that

the suction and discharge flanges are plumb, level, and

at the correct elevation. It is normal practice to set the

mounting pads slightly low in order to permit lowering of

units which may be required to suit future piping or

minor changes. Place washers over the foundation

bolts and install nuts. Tighten finger tight only.

Check the impeller axial clearance and that the rotor

turns freely by hand.

Note: Grout is not poured until an initial alignment

of the pump and driver has been performed.