M SLURRY USER

INSTRUCTION ENGLISH 71569241 - 02/08

Page 42 of 60

®

c) Assemble the line bearing cover [3260] over the

shaft and squarely into the bearing frame bore.

Fasten to the bearing frame with capscrews,

washers and hex nuts. Tighten firmly, but not

excessively.

d) Assemble the deflector [2540] loosely over the shaft

but do not tighten the set screws.

e) Install the coupling key [6700] and tape to the shaft.

f) Rotate the shaft and check that runout does not

exceed 0.002 inch [0.050 mm).

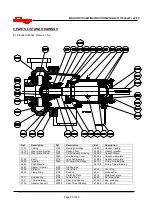

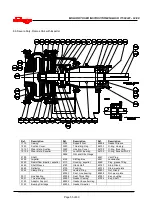

6.10.5.2 Frames 5 & 6

a) Install the lip seal [4300] into the line bearing

cover [3260].

b) Assemble the gasket [4590.4] onto the face of the

line bearing cover [3260].

c) Assemble the line bearing cover [3260] over the

shaft and squarely into the bearing frame bore.

Fasten to the bearing frame with capscrews,

washers and hex nuts. Tighten firmly but not

excessively.

d) Assemble the deflector [2540] with a slight gap

(0.06") to the line bearing cover [3260].

e) Install the coupling key [6700] and tape to the

shaft.

f) Rotate the shaft and check that run-out does not

exceed 0.002 inch (0.050 mm).

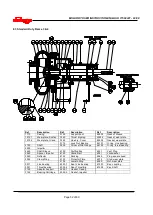

6.10.6 Stuffing box

6.10.6.1 All

a) Install the gland studs [6572] using Loctite grade A

or equivalent. Install the square head plugs [6569] in

the stuffing box as required using pipe sealant.

b)

Install the shaft sleeve onto the shaft. The hock

type sleeve must be seated against the shaft

shoulder. Application of Loctite is not necessary

as impeller tightening torque during operation is

sufficient to ensure sleeve rotation.

6.10.6.2 Standard packing

a) Install the protector plate [4132] in the stuffing box

head [4100]. Heavy grease may be applied to

mating faces to help hold it in position while

assembling the stuffing box head to the gland side

wear plate [1915].

b) With gland side wear plates facing up, lift the

stuffing box head [4100] and lower onto the wear

plate.

c) Place the seal washers [4590] over the studs

followed by the steel washers. Apply Loctite 242

or equivalent to nut threads and fasten wear plate

in position. Torque nuts per table.

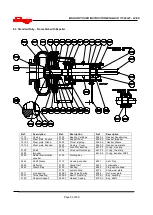

d) Assemble the stuffing box head [4100] over the

shaft sleeve [2445] and orientate the lantern ring

connections to suit auxiliary pipe These

connections are normally placed on the vertical

centerline for proper venting and draining as well

as providing optimum gland stud access.

e) Push the stuffing box head [4100] back against

the pedestal support flange face and clamp into

position. Back off the thrust bearing housing jack

screw and tighten the thrust bearing housing hold

down capscrews to slide the rotor assembly

forward such that the end face of the shaft sleeve

[2445] protrudes beyond the face of stuffing box

head (standard packed pumps only).

f)

Install the shaft sleeve gasket [4590] on the shaft,

ensuring that the outside diameter is no larger

than the sleeve.

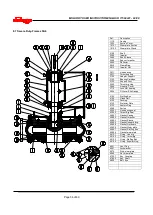

6.10.6.3 Optional expeller seal-frame 1, 2, 3 & 4

a) Assemble the stuffing box [4100] over the sleeve

[2445] and into the bearing frame [3122] register.

Orient the grease fitting to suit the installation. Note

that if the optional solid gland with lip seal design is

used, it must be installed first.

b) Install O-ring onto the expeller stuffing box (corner

for frames 1 & 2, groove for frames 3 & 4). Install

expeller wearplate [1915.3] onto the stuffing box.

Some units may be built with a 1 pc stuffing

box/wearplate. In this cause this step will be

eliminated.

c) Install the expeller [2250] over the shaft sleeve.

Expeller should seat against the sleeve shoulder

but be clear of the expeller wearplate [1915.3].

Adjust the shaft [2100] forward to ensure that the

expeller [250] when installed will not bind against the

stuffing box head [4100].

d) Install gasket [4590.4] over expeller to face of

stuffing box [4100].

e) Install expeller housing [4110] to stuffing box

[4100], clamp in place.

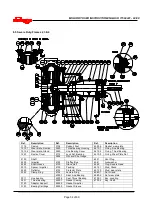

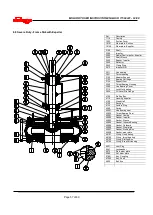

6.10.6.4 Optional expeller seal-frame 5

a) Install the gland studs [6572] into the loose

stuffing box [4100] using Loctite grade A or

equivalent. Install the square head plug [6569]

and grease nipple [6569] in the stuffing box as

required using pipe sealant. For further

information see sections on packing earlier in this

manual.

b) Install studs in expeller wearplate [1915.3], secure

using Loctite #242.

c) Mount gasket [4590.3] onto wearplate [1915.3]

and install loose stuffing box [4100]. Note location

of grease nipple relative to any lifting facility.

d) Assemble the expeller wearplate/stuffing box over

the sleeve [2445] and into the adaptor support

[3120] register. Orientate the grease fitting to suit

the installation. Clamp in position for safety.

e) Adjust the shaft [2100] forward to ensure that the

expeller [2250] when installed will not bind against

the expeller wearplate [1915.3].