M SLURRY USER

INSTRUCTION ENGLISH 71569241 - 02/08

Page 43 of 60

®

f) The shaft sleeve is grooved for an o-ring [4610].

Lubricate the o-ring and install.

g) Install the expeller [2250] onto the shaft sleeve

[2445] vanes first.

h) Using a locking collar secure the expeller in place.

i) Install the gasket [4590.1] into the expeller housing

[4110] recess. Use a small amount of lubricant to

hold in place. Remove clamps holding the

wearplate in place. Assemble the expeller housing

[4110] onto the wearplate [1915.3]. Clamp the

housing in place.

j)

Remove locking collar and assemble gasket

[4590.2] onto the shaft and seat against the

expeller hub face.

6.10.7 Impeller Installation

a) Install the impeller spacer [2460] on standard

pumps only and install the impeller gasket [4590.2]

on all pumps.

b) Due to the method of assembling the impeller, it is

recommended to smear the sleeve face and both

sides of the impeller spacer [2460] with a heavy

grease or a silicon sealant before assembling onto

the shaft which will help to hold the impeller spacer

in position during assembly.

c) For 2.5M182 only - The impeller requires an

adapter bushing to match the shaft threads. If a

new impeller is being installed an insert must be

installed. Thread the insert into the impeller and

lock into position using Loctite 242.

d) Apply anti-seize compound to the shaft threads and

screw the impeller onto the shaft. For large sizes it

is more practical to hold impeller using a sling and

hoist and turn the shaft.

Failure to tighten the impeller [2200]

spacer [2460] securely against the sleeve may

cause serious damage to pump components.

The thread is designed so that during

operation the impeller will tend to tighten onto shaft.

Therefore a clockwise shaft rotation (looking from

coupling end) will screw impeller on.

e) Release the thrust bearing housing hold down bolts

and tighten the jacking screws to pull the impeller

back to the stuffing box head [4100]. The stuffing box

head must not be rigidly clamped.

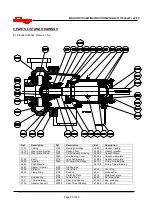

6.10.8 Suction Side Wearplate

a) Install the studs [6572] in the wearplate [1915] using

Loctite grade A or equivalent.

6.10.8.1 Standard Duty Pumps

a) Lift wearplate and install into casing.

b) Place the sealing washer [4590.5] over the studs

[6572]. Secure wearplate [1915] in place using hex

nuts and washers using Loctite 242 or equivalent.

Tighten in accordance with Table tables in section

6.6.

Excessive or uneven tightening torque may distort wearplate

affecting impeller running clearances or result in broken

studs.

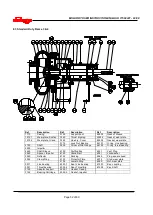

6.10.8.2 Severe Duty Pumps

a) Lift suction cover [1223] and mount over the suction

side wearplate [1915].

b) Install o-ring into enclosed hex nuts. A small amount

of lubricant would be usefull to hold the o-ring in

place.

c) Fasten wearplate to cover with the enclosed nuts.

Tighten in accordance with Table tables in section 6.6.

Excessive or uneven tightening torque may distort wearplate

affecting impeller running clearances or result in broken

studs.

d) Place the casing [1110] on a clean section of the

floor with the discharge pointing counter-

clockwise. Refer also to the pump elevation

drawing if applicable.

e) Apply heavy grease to casing gasket [4590] and

place in position on the casing flange.

f) Lower the suction cover assembly [1223] into the

casing. Tighten the casing bolts. The casing to

suction cover gap is approximately .050 inches at

which point the casing gasket should be

compressed.

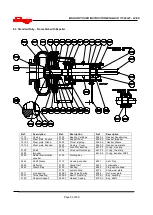

6.10.9 Casing

a) Smear a small amount of grease or anti-seize

compound over one face of the gasket [4590] and

place it on the stuffing box head [4100] with coated

face against flange.

b) Lift the casing and assemble to the pedestal. The

discharge may be orientated to various

configurations. Check the installation or GA drawing

for the proper position.

c) Secure into position. Ensure that the impeller is free

to rotate before torquing bolts.

d) Set the impeller front clearance in accordance with

instruction earlier in this section of the manual.

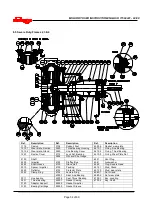

6.10.10 Shaft seal

6.10.10.1 Packing

a)

The two piece lantern ring [4134] must be installed

first for standard L5. Push the lantern ring and

previously installed packing. The ports in the lantern

ring do not need to be aligned with the inlet/outlet

ports.

b)

Insert one packing ring at a time into the stuffing box.

Push the packing as far as possible into the packing