GEI 56128-L

© Copyright 2016 General Electric Company

20

XII.

Lubrication Guide

(Excerpt from: GEK-72836E)

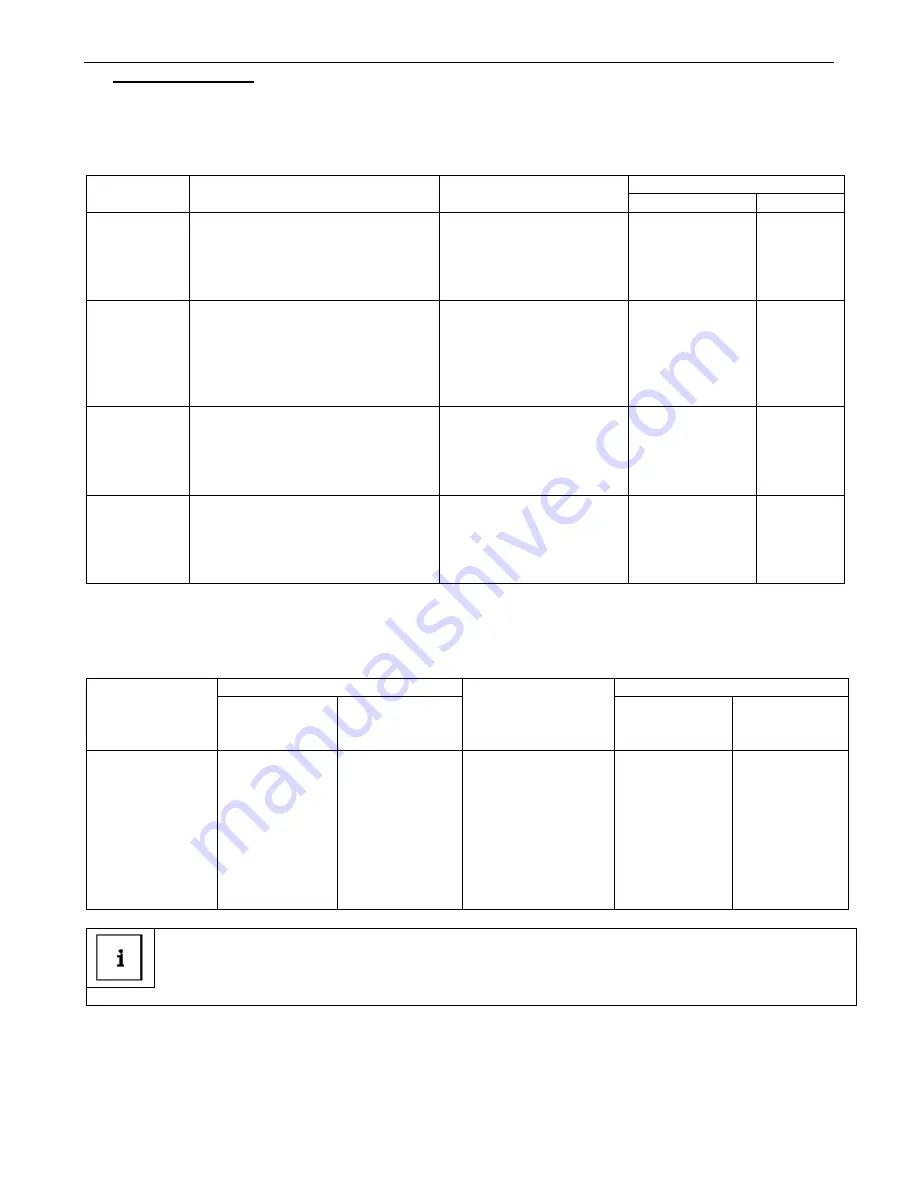

Table 5: Motor Lubrication Guide

Type of

Service

Typical Examples

HP Range

Lubrication Interval (Yrs.)

Horizontal

Vertical

Easy

Valves, door openers, portable floor

sanders, motor operating

infrequently (one hour per day)

1 – 7.5

10 – 40

50 – 150

200 – 350

400 - 1000

10

7

4

3

1

9

3

1.5

9 months

---

Standard

Machine tools, air-conditioning

apparatus, conveyors (one or two

shafts), garage compressors,

refrigeration machinery, laundry

machinery, oil well pumps, water

pumps, woodworking machinery

1 – 7.5

10 – 40

50 – 150

200 – 350

400 - 1000

7

4

1.5

1

6 months

3

1

6 months

3 months

---

Severe

Motor for fans, MG- sets, etc., that

run 24 hours per day, 365 days per

year; coal and mining machinery;

motors subject to severe vibration;

steel mill machinery

1 – 7.5

10 – 40

50 – 150

200 – 350

400 - 1000

4

1.5

9 months

6 months

3 months

1.5

6 months

3 months

1.5 months

---

Very

Severe

Dirty, vibrating applications; where

end of shaft is hot (pumps and fans);

high ambient temperature

1 – 7.5

10 – 40

50 – 150

200 – 350

400 - 1000

9 months

4 months

4 months

3 months

2 months

6 months

3 months

2 months

1 month

---

Table 6: Number of Grease Gun Pumps

Bearing Size on

Motor Nameplate

Number of Pumps

Bearing Size on

Motor Nameplate

Number of Pumps

16 Oz. Gun

(Approx. 475

mL)

24 Oz. Gun

(Approx. 700 mL)

16 Oz. Gun

(Approx. 475

mL)

24 Oz. Gun

(Approx. 700

mL)

6205

5

3

6312

40

27

6206

6

4

6314

50

35

6208

10

7

6315; C 2315

65

45

6210

25

17

6316

60

40

6213

35

23

6318; NU 318

75

50

6220

58

39

6320; NU 320; C

2320

95

65

6309

20

13

6321

153

102

6310

25

17

6324; NU324

246

164

NOTE: A standard 10,000 PSI (69 kPa) 16 ounce (475 mL) grease gun delivers approximately 0.04 oz. (1.18

mL) of grease with each pump, and a 24 oz. (710 mL) gun delivers approximately 0.06 oz. (1.77 mL) of

grease. The number of pumps listed represents approximately 20% of the total grease cavity volume in

end shield.