FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 15 of 32

flowserve.com

4 INSTALLATION

Equipment operated in hazardous locations

must comply with the relevant explosion protection

regulations. See section 1.6.4,

Products used in

potentially explosive atmospheres.

All equipment must be grounded.

4.1 Location

The pump should be located to allow room for

access, ventilation, maintenance and inspection with

ample headroom for lifting and should be as close

as practicable to the supply of liquid to be pumped.

4.2 Foundation

There are many methods of installing

pump units to their foundations. The correct method

depends on the size of the pump unit, its location

and noise vibration limitations. Non-compliance with

the provision of correct foundation and installation

may lead to failure of the pump and as such would

be outside the terms of the warranty.

Anchor bolts must be appropriate for the foot bolt

holes. Use anchor bolts of accepted standards and

sufficient length so that they may be clamped safely

in the grout.

NF E 27 811

Provide sufficient space in the foundation to

accommodate the anchor bolts. If necessary, provide

concrete gullets.

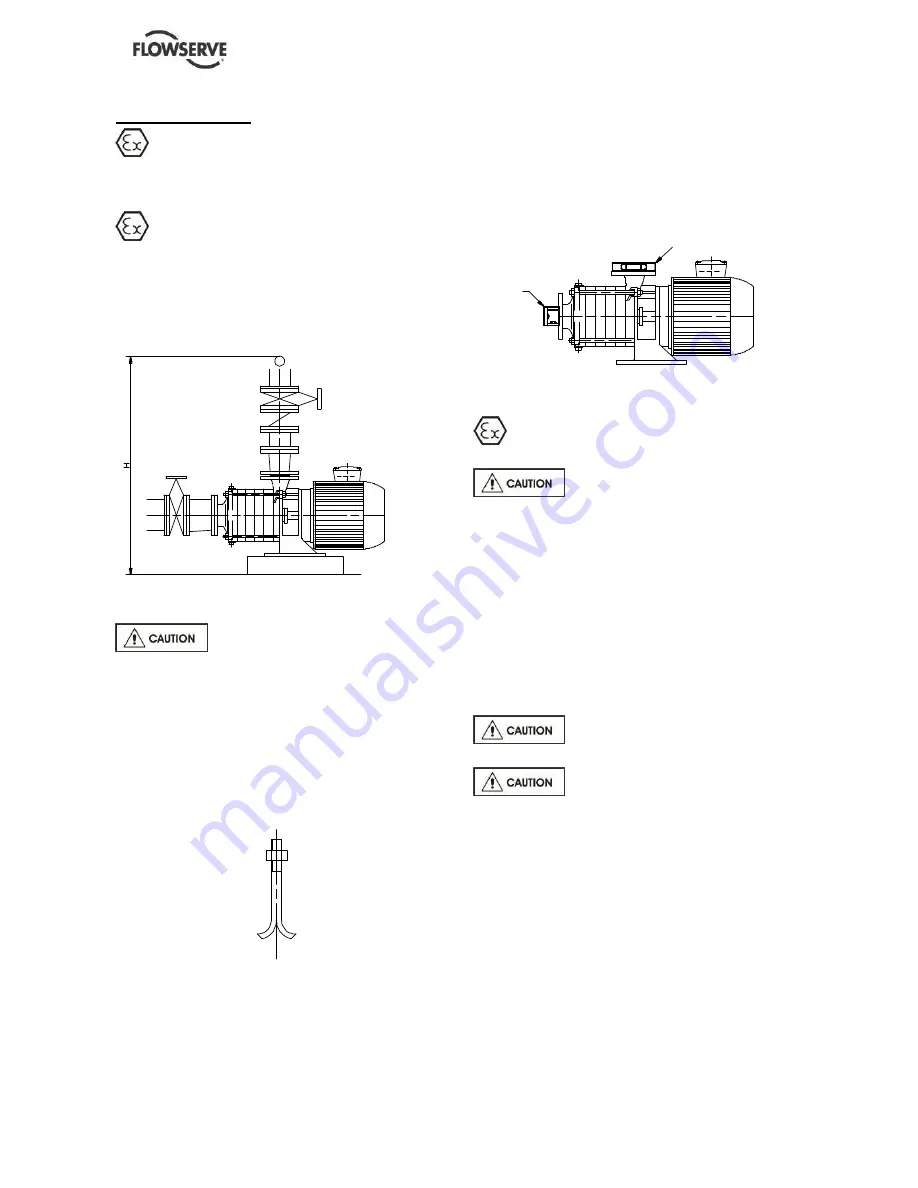

a) Levelling on the suction flange with a frame level

or on the discharge flange with a levelling

instrument .

b)

Admissible defect 0.5 mm for 1 meter (0.02 in

for 3.3 ft).

c)

Wedge under the pump.

Level

Frame

level

4.3 Piping

The user must verify that the equipment is

isolated from any external sources of vibration.

Protective covers are fitted to the

pipe connections to prevent foreign bodies entering

during transportation and installation. Ensure that

these covers are removed from the pump before

connecting any pipes.

4.3.1 Suction and discharge piping

The dimensions of the pipes do not directly depend

on suction and discharge diameters of the pump:

a) First, choose a flow speed < 2 m/s (7 ft/s) at

suction, and about 3 m/s (10 ft/s) at discharge.

b)

Take into account the available NPSH, which

must be superior to the required NPSH of the

pump.

Never use pump as a support for

piping.

Do not mount expansion joints in

such a way that their force, due to internal pressure,

may act on the pump flange.

Maximum forces and moments allowed on the pump

flanges vary with the pump size and type. These

external strains may cause misalignment, heating of

the bearings, vibrations and the possible failure of

the pump casing.

When designing the pipework (§ 5.3.1, § 5.3.2, §

5.3.3) take necessary precautions in order not to

exceed maximum allowed strains.

Forces and moments applied to the pump flanges

must never exceed the values shown in the following

table: