FM USER INSTRUCTIONS ENGLISH 71576526 - 03/07

Page 20 of 32

flowserve.com

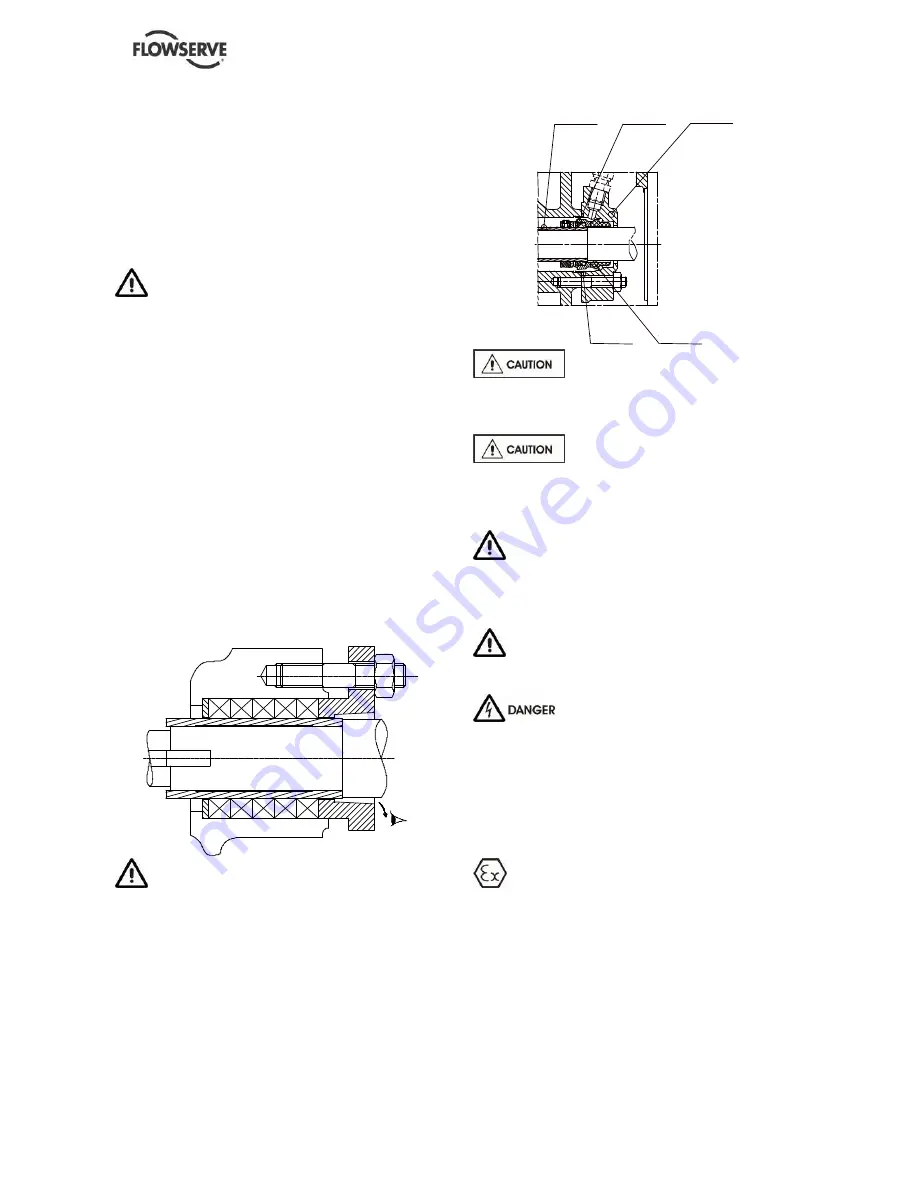

5.5.2 Pump fitted with a stuffing box

If the pump has a packed gland there must be some

leakage from the gland. Gland nuts should initially

be finger-tight only. Leakage should take place soon

after the stuffing box is pressurized. If no leakage

takes place the packing will begin to overheat. If

overheating takes place the pump should be

stopped and allowed to cool before being re-started.

When the pump is re-started it should be checked to

ensure leakage is taking place at the packed gland.

When adjusting an operating stuffing box

(shield grids removed for this operation), the

operator must be very careful. Safety gloves are

compulsory and loose clothes are not allowed

(above all to the arms) to avoid being caught by the

pump shaft.

The pump should be run for ten minutes with steady

leakage and the gland nuts tightened by 10 degrees

at a time until leakage is reduced to an acceptable

level.

The temperature of the gland should be checked

after each round of tightening. If the temperature

starts to climb rapidly then back off the gland nuts

until the temperature drops down. Wait for the

temperature to stabilize before tightening again.

The leakage must not be reduced below a rate of 20

drops per minute. Bedding in of the packing may

take several hours.

Shield grids being removed during installation

of the gland packing, it must be ensured that they

are replaced as soon as this operation is completed.

5.5.3 Pump fitted with a mechanical seal

A mechanical seal ensures a seal without leakage

and does not need any adjustment. Nevertheless if a

light leakage occurs during start-up, it should

disappear after the initial running in of the friction

faces.

4213

4200

2445

4240

4610

With a mechanical seal, the

maximum temperature is limited to 80 °C (176 °F)

whatever the internal construction of the pump is

(Cast iron or Bronze).

NEVER RUN A MECHANICAL SEAL

DRY, EVEN FOR A SHORT WHILE.

SAFETY INSTRUCTIONS WHEN THE PUMP IS

RUNNING:

If hot or freezing components of the machine

can present a danger to operators, they must be

shielded to avoid accidental contact. If a 100 %

protection is not possible, the machine access must

be confined to the maintenance staff only.

If the temperature is greater than 80 °C (176

°F), a warning plate must be clearly placed on the

pump.

It is strictly forbidden to open switch

cupboards, switch boxes, or all other live electric

equipment. If it is necessary to open them in order to

take readings, to carry out tests or adjustments for

example, only a skilled technician may do them with

adapted tools. Make sure that physical protections

against electrical risks are used.

5.5.4 Bearings

If the pumps are working in a potentially

explosive atmosphere, temperature or vibration

monitoring at the bearings is recommended. If

bearing temperatures are to be monitored it is

essential that a benchmark temperature is recorded

at the commissioning stage and after the bearing

temperature has stabilized.

Record the bearing temperature (t) and the

ambient temperature (ta)

Estimate the likely maximum ambient

temperature (tb)