UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 25 of 32

®

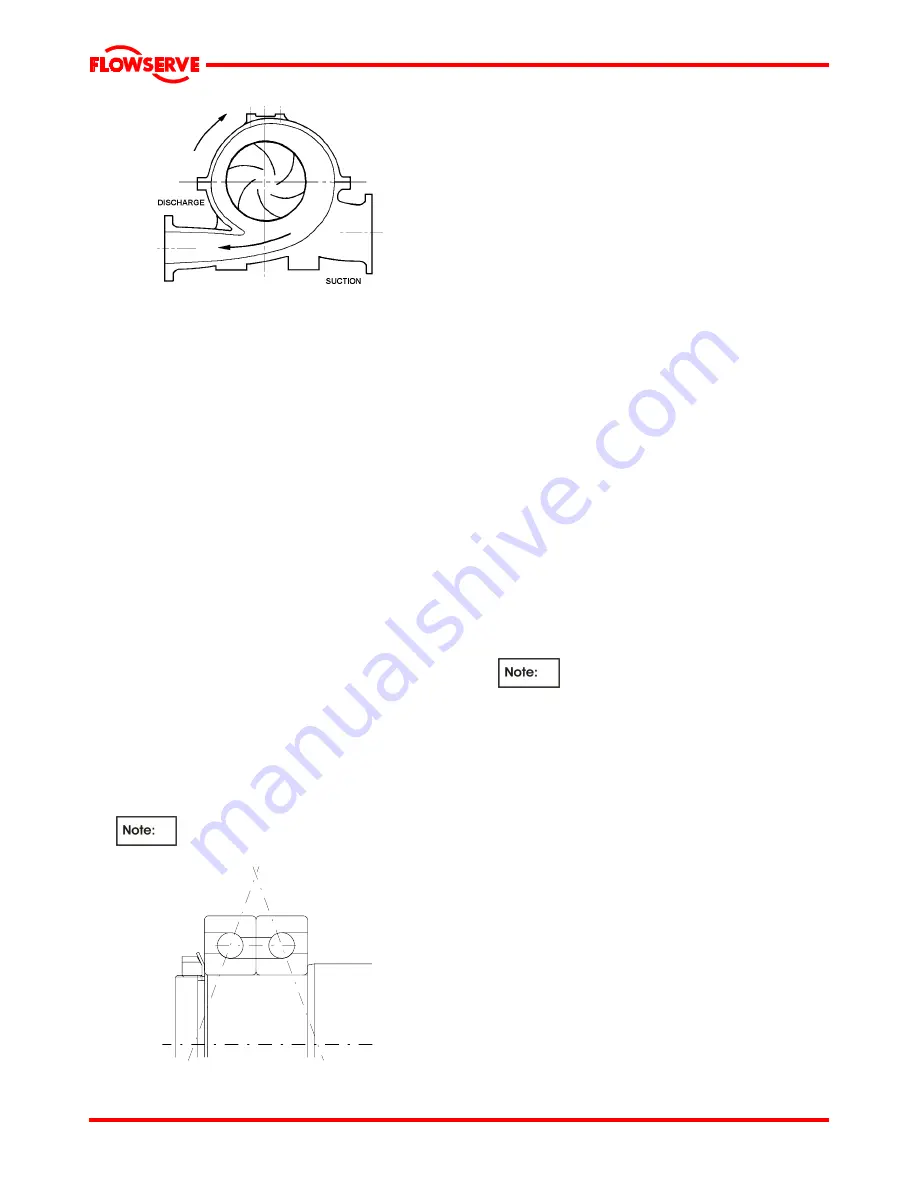

The rotor always rotates towards the expanding

section of the volute

c) The diaphragm plate complete with its bush must

be fitted on to the shaft between the two impellers.

d) Fit the two shaft sleeves, O-rings (when fitted)

and shaft nuts and lightly secure the impellers on

the shaft. Take care to protect the sleeve O-rings

(when fitted) from damage on the shaft threads.

The sleeves and nuts define the impeller position

on the pump shaft and hence in the pump casing.

Initially position the impellers centrally on its

keyway. This position may be adjusted slightly

later on in the assembly process.

e) It is recommended that gasket sealing compound

Loctite 574 or equivalent is used between sleeve

and impeller mating faces to protect the shaft

from the liquid pumped.

f) When mechanical seals are fitted the rotating

parts can be slid onto the sleeves before the

sleeves are fitted onto the shaft. The seal locking

collars should be left loose.

Refer to any special instructions supplied

with the mechanical seal.

g) If gland packing is used fit the glands.

h) Fit seal covers complete with seal seat, water

throwers and bearing covers complete with

gaskets.

i) Fit the bearings onto the shaft. The main thrust

bearing is at the non-drive end.

Where double row bearings are fitted

these must be assembled 'back to back' as below:

The bearings must be heated up to 100 ºC (212 ºF)

using a hot plate, oil bath or induction heater and

slid onto the shaft. Ensure bearing is fully seated

against the bearing distance piece and the distance

piece is located up to the shaft shoulder.

j) Fill both sides of bearing with grease.

k) Fit the bearing lockwasher and tighten the

bearing shaft nut.

l) Peen a segment of the copper lockwasher over a

flat on the bearing locknut.

m) Slip casing rings, loosely over the impeller hubs.

n) Slide the bearing housings over the bearings.

Ensure bearings are located square in the

bracket bore.

o) One third fill the space between bearing cover

and bearing with grease. Secure bearing cover,

complete with gasket.

p) Fit the coupling distance piece and pump half

coupling. Fit copper lockwasher and secure

coupling nut. Peen a segment of the copper

lockwasher over a flat on the coupling nut.

6.10.4 Casing lower half

a) If required, drive in two new locating dowels on

the horizontal flange.

b) Coat the faces of the bearing housing brackets

with liquid sealant to protect against corrosion.

c) Place the complete rotating assembly into the

casing ensuring that impeller rings and diaphragm

plate are in the correct position to allow the anti-

rotation tongues to locate correctly in the anti-

rotation grooves in the casing bores.

The anti-rotation grooves in the bottom

half casing are bigger in diameter than those in

the top.

d) Locate the bearing housings in the machined

spigots in the casing and torque up the fixing

screws.

e) Check rotor for free rotation.

f) Centralize the impellers within the casing

waterway by adjusting the shaft nut, if necessary.

Using a C-spanner fully tighten the shaft nuts and

lock with the two radial socket head screws.

g) Set the seals, if fitted, to the correct working

length and tighten the seal collar screws.

Refer to any special instructions supplied

with the mechanical seal.

h) Check for free rotation.