UB USER INSTRUCTIONS ENGLISH 71569247 07-04

Page 22 of 32

®

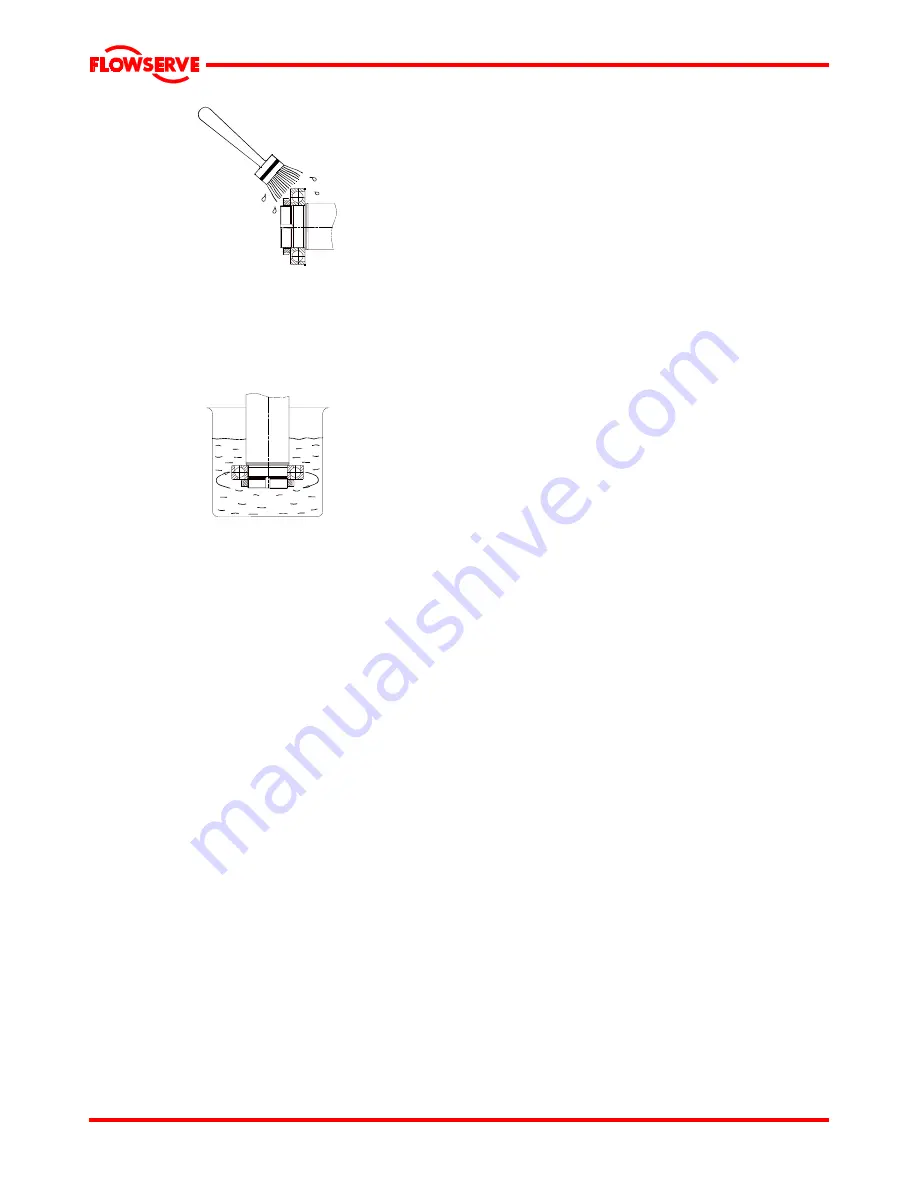

To remove badly oxidized grease that refuses to

come off:

a) Support the rotor in a vertical position and

immerse the bearing in hot kerosene or a mixture

of alcohol and light mineral solvent.

b) Gently spin the bearing outer ring.

c) Dry and reflush the bearing with clean light oil.

d) It is important not to under or over grease the

bearings as this will lead to over heating and

premature failure. It is recommended that the

bearings be filled with grease using a suitable

spatula. In addition the housings should be no

more than half filled.

6.2.4 Mechanical seals

No adjustment is possible. When leakage reaches

an unacceptable level the seal will need replacement.

6.2.5 Gland packing

The stuffing box gland can be backed off for

re-packing or to enable the addition of extra rings of

packing.

The stuffing box is normally supplied with a lantern

ring to enable a clean or pressurised flush to the

centre of the packing. If not required, this can be

replaced by an extra 2 rings of packing.

There must always be a small leakage, normally a

minimum of 120 drops per minute to atmosphere to

lubricate and cool the packing is required.

6.3 Spare parts

6.3.1 Ordering of spares

Flowserve keeps records of all pumps that have been

supplied. When ordering spares the following

information should be quoted.

1) Pump

serial

number.

2) Pump

size.

3) Part name – taken from section 8.

4) Part number – taken from section 8.

5) Number of parts required.

The pump size and serial number are shown on the

pump nameplate.

To ensure continued satisfactory operation,

replacement parts to the original design specification

should be obtained from Flowserve. Any change to

the original design specification (modification or use

of a non-standard part) will invalidate the pump’s

safety certification.

6.3.2 Storage of spares

Spares should be stored in a clean dry area away

from vibration. Inspection and re-treatment of

metallic surfaces (if necessary) with preservative is

recommended at 6 monthly intervals.

6.4 Recommended spares and

consumable items

For start up purposes:

1 - complete set of gland packing

2 - shaft sleeves

1 - set of gaskets and seals

(optional: 2 - mechanical seals)

For 2 years operation:

1 - set of bearings (line and thrust)

2 - sets of gland packing

2 - shaft sleeves

2 - sets of gaskets and seals

2 - lantern rings

2 - casing wear rings

1 – diaphragm bush

(optional: 2 - mechanical seals

2 - impeller wear rings)

For 4 years operation:

1 - set of bearings (line and thrust)

2 - sets of gland packing

2 - shaft sleeves

2 - sets of gaskets and seals

2 - lantern rings

2 - casing wear rings