MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 11 of 28

flowserve.com

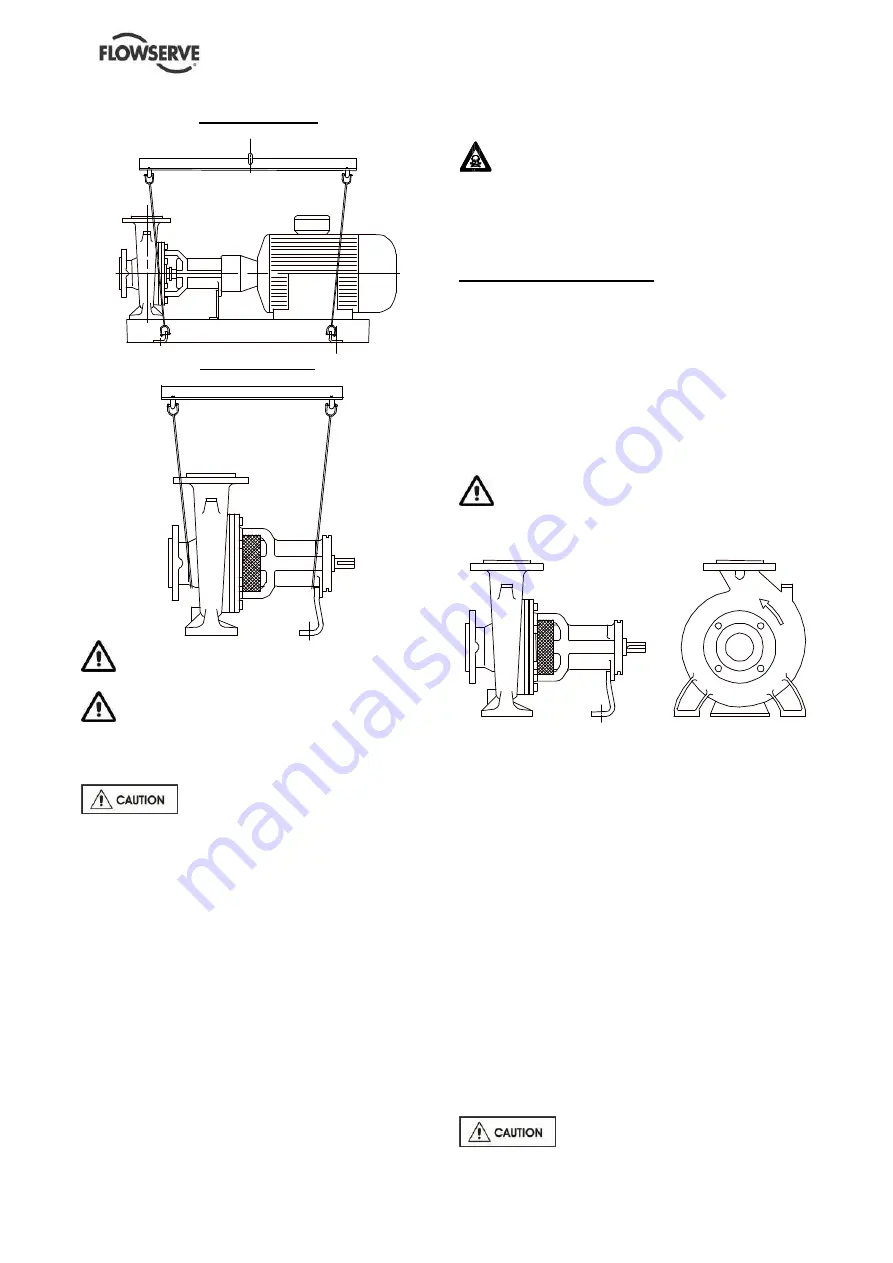

Motor pump unit

Bareshaft pump

When handling always wear gloves, safety

boots and an industrial safety helmet.

For masses above 25 kg (55 lb), manual

handling is forbidden.

2.4 Storage

Store the pump in a clean, dry

location away from vibration. Leave piping

connection covers in place to keep dirt and other

foreign material out of pump casing. Turn pump at

intervals to prevent brinelling of the bearings and the

seal faces, if fitted, from sticking.

Do not store pumps starting on the fan guard.

The pump may be stored as above for up to 6

months. Consult Flowserve for preservative actions

when a longer storage period is needed.

2.5 Recycling and end of product life

At the end of the service life of the product or its

parts, the relevant materials and parts should be

recycled or disposed of using an environmentally

acceptable method and local regulations. If the

product contains substances which are harmful to

the environment, these should be removed and

disposed of in accordance with current regulations.

This also includes the liquids and or gases in the

"seal system" or other utilities.

Make sure that hazardous substances or toxic

fluid are disposed of safely and that the correct

personal protective equipment is used. The safety

specifications must be in accordance with the current

regulations at all times.

3 PUMP DESCRIPTION

3.1 Configurations

The centrifugal motor pump is designed for the

pumping of cold water or all clear liquids which are

not solid and liquid mixtures, non-corrosive, non-

abrasive when in contact with the pump motor unit

and its working parts (Important: for other liquids

consult Flowserve for beforehand advice).

The MHP-TN pump is a centrifugal, single-stage

pump with axial inlet and outlet in the vertical axis.

The pump must be stored in a non explosive,

ventilated location, sheltered from bad weather, dust

and vibrations.

The reliability of the delivered machine can only be

ensured if it is used according to the conditions given

in this manual. The maximum values specified in this

manual must never be exceeded.

Maximum working pressure at discharge

................................................. 16 bar (232 psi)

Maximum working pressure at suction

................................................. 10 bar (145 psi)

Maximum pumped fluid temperature

- Gland packing without cooling

..............................................

105 °C (221 °F)

Minimum pumped fluid temperature

.................................................... -10 °C (14 °F)

Maximum ambient temperature .... 40 °C (104 °F)

Maximum solid suspension

........................................ 50 g/m

3

(0.003 lbm/ft

3

)

Density .................................. 1

Viscosity ................................ 1 mm

2

/s (31 SSU)

Maximum rotation speed (frequency 50 Hz)

.......................................................

2900 min

- 1

The maximum speed is shown on the

pump nameplate.