MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 15 of 28

flowserve.com

It is only necessary to rectify the adjustment under

base plate. If it proves to be insufficient, modify the

motor and the piping.

Pump and motor mounted on individual base

plates:

Machines are (or must be) first mounted on their

own base plate in the workshop. Once the pump is

set, it will be regarded as the fixed piece. Any

alignment necessary shall be carried out on the

motor.

Never connect the electric motor

before the setting has been completely finished.

4.5 Piping

The user must verify that the equipment is

isolated from any external sources of vibration.

Protective covers are fitted to the

pipe connections to prevent foreign bodies

entering during transportation and installation.

Ensure that these covers are removed from the

pump before connecting any pipes.

4.5.1 Suction and discharge piping

The dimensions of the pipes do not directly

depend on suction and discharge diameters of the

pump:

a) First, choose a flow speed < 2 m/s (7 ft/s) at

suction, and about 3 m/s (10 ft/s) at discharge.

b)

Take into account the available NPSH, which

must be superior to the required NPSH of the

pump.

Never use pump as a support for

piping.

Do not mount expansion joints in

such a way that their force, due to internal

pressure, may act on the pump flange.

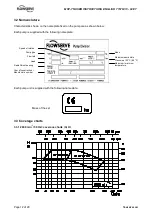

Maximum forces and moments allowed on the

pump flanges vary with the pump size and type.

These external strains may cause misalignment,

hot bearings, worn couplings, vibrations and the

possible failure of the pump casing.

When designing the pipes (§ 4.5.2.1, § 4.5.2.2, §

4.5.3.1) take necessary precautions in order not to

exceed maximum allowed strains.

Forces and moments applied to the pump flanges

must never exceed the values shown in the

following table:

Forces

Suction

DNA

Discharge

DNR

Fv

max

Fh

max

Moments

Mt max

Pump type

mm

(in.)

mm

(in.)

daN

(lbf)

daN

(lbf)

m.daN

(lbf.ft)

MHP-TN

100-65-315

100

(4”)

65

(2”1/2)

140

(315)

105

(236)

27

(199)

MHP-TN

125-100-315

125

(5”)

100

(4”)

180

(405)

125

(281)

47

(347)

Forces and moments values are applied to the

whole flanges and not flange -by-flange. For their

sharing out on the pump flanges, refer to standard

NFCR 13 931.

Ensure piping and fittings are

flushed before use.

Ensure piping for hazardous liquids is

arranged to allow pump flushing before removal of

the pump.

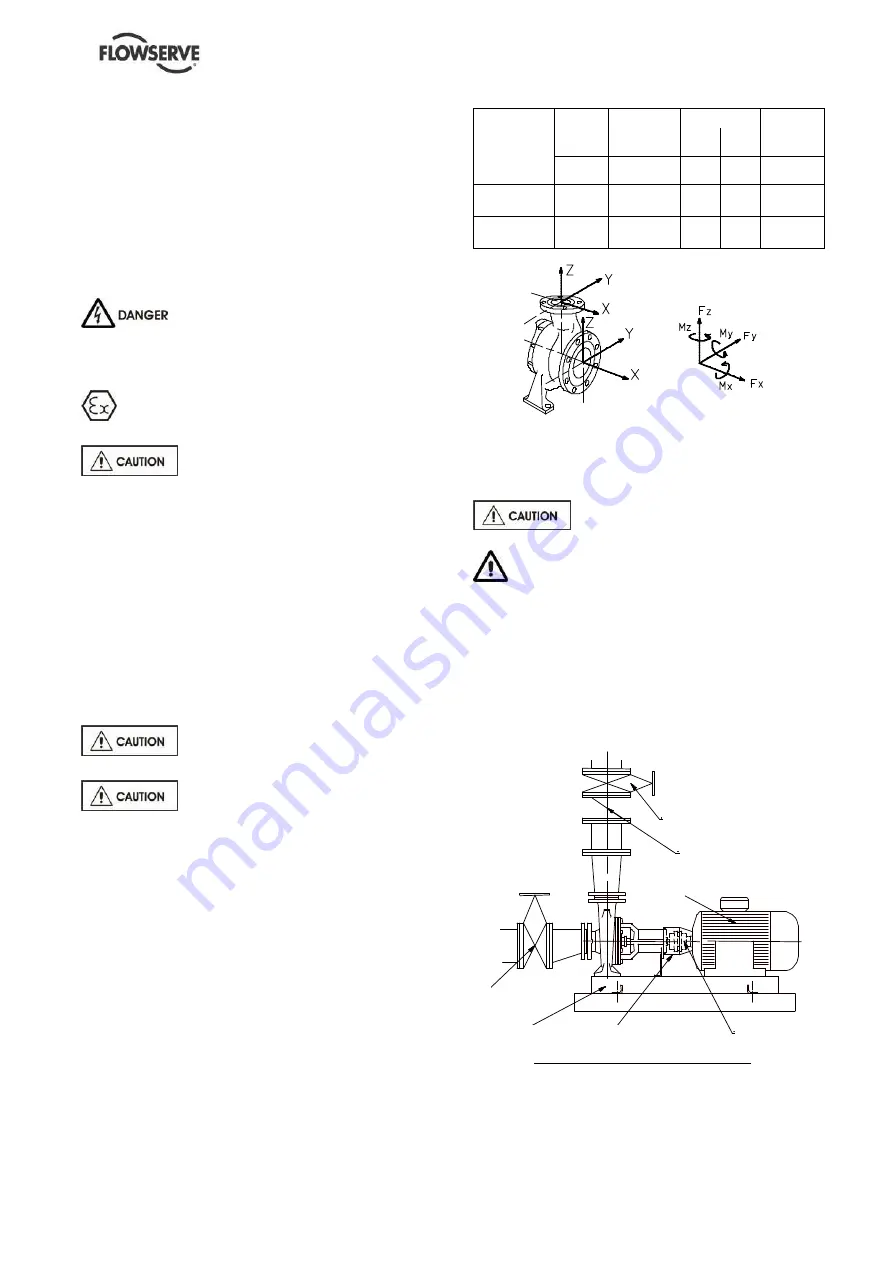

4.5.2 Suction piping

4.5.2.1 Design of a flooded suction line

The suction line must be as short and direct as

possible, never mount an elbow directly on the

inlet flange of the pump.

Valve

Non return valve

Coupling

Coupling guard

Motor

Baseplate

Continuous

flow valve

Flooded suction configuration

a)

Avoid sharp elbows or sudden narrowing. Use

convergent

20° (total angle).

b)

Arrange the piping so that there are no air

pockets (no bulges).