MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 16 of 28

flowserve.com

c)

If high points cannot be avoided in suction line,

provide them with air relief cocks.

d)

If a strainer is necessary, its net area should

be three or four times the area of the suction

pipe.

e) If an inlet valve is necessary, choose a model

with direct crossing.

Do not tighten flanges before the

final check (see § 4.5.4).

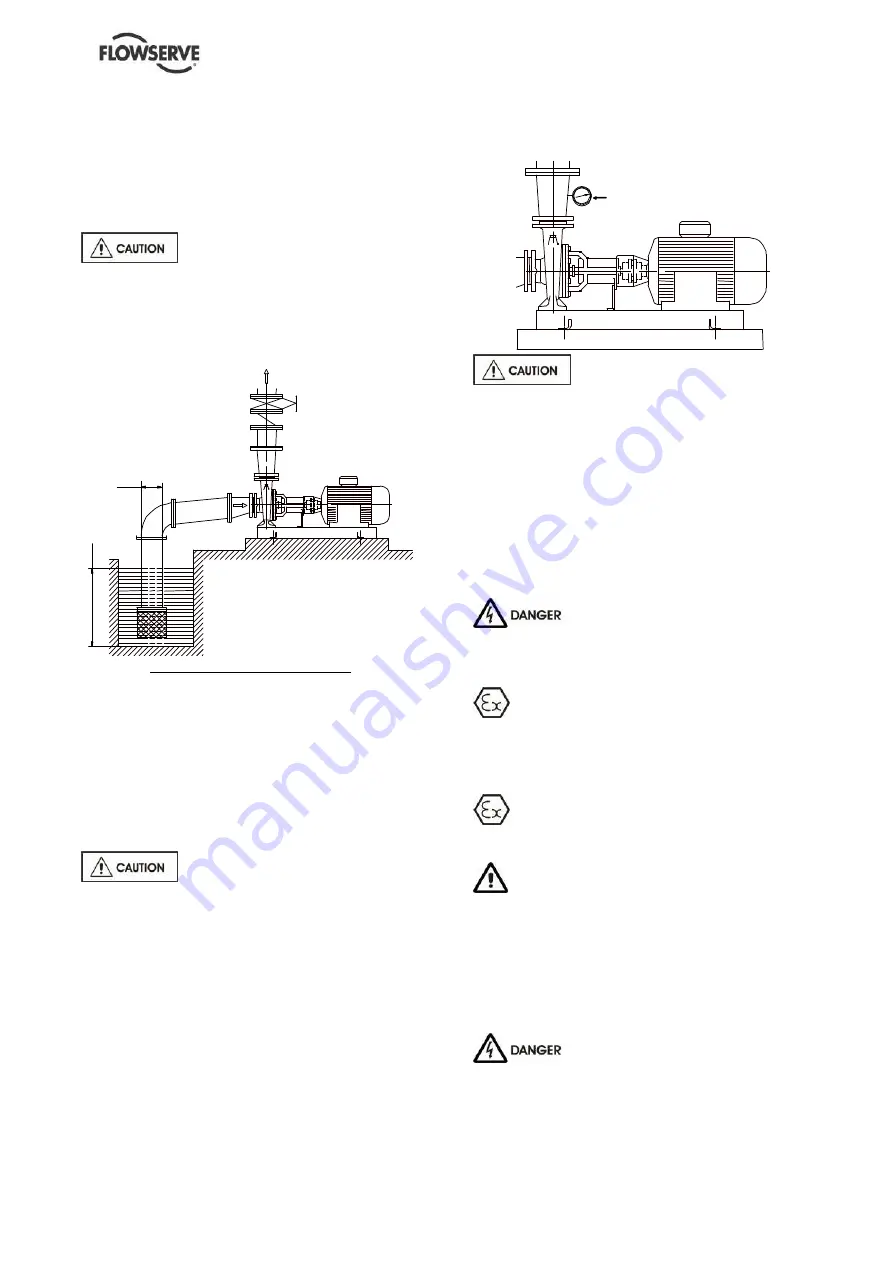

4.5.2.2 Design of a suction lift line

The inlet pipe must be as short and as direct as

possible, never place an elbow directly on the

pump inlet nozzle.

I

Sufficient

immersion

D

I

3 x D

Sump suction configuration

a) Avoid sharp elbows or sudden narrowing. Use

convergent

20° (total angle) with upright

generating.

b)

Arrange that the suction piping is inclined

upwards towards the pump ensuring that there

are no peaks.

c)

If a foot valve is necessary, do not oversize it

because it would generate pulsations (valve

beating).

Do not tighten flanges before the

final check (see § 4.5.4).

4.5.3 Discharge piping

4.5.3.1 Design of a discharge line

a) If discharge line is provided with a divergent,

its total angle will be between 7° and 12°.

b)

Install the discharge valve after the non-return

valve downstream.

The non-return valve will be set in the discharge

pipe to protect the pump from any excessive

pressure surge and from reverse rotation.

If necessary, a control manometer (pressure

gauge) can be connected on the piping.

Control manometer

Do not tighten flanges before the

final check (see § 4.5.4).

4.5.4 Final checks

a)

Check the tightening of anchor bolts. Tighten

them if necessary.

b)

Check that protective covers on suction and

discharge flanges are removed.

c)

Check that holes of piping flanges are parallel

and correspond to those of the pump.

d)

Tighten suction and discharge flanges.

4.6 Electrical connections

Electrical connections must be made

by a qualified Electrician in accordance with

relevant local national and international

regulations. This includes any grounding.

It is important to be aware of the

EUROPEAN DIRECTIVE on potentially explosive

areas where compliance with IEC60079-14 is an

additional requirement for making electrical

connections.

Avoid mechanical, hydraulic or electrical

overload by using motor overload trips or a power

monitor and make routine vibration monitoring.

It is important to be aware of the EUROPEAN

DIRECTIVE on electromagnetic compatibility when

wiring up and installing equipment on site. Attention

must be paid to ensure that the techniques used

during wiring/installation do not increase

electromagnetic emissions or decrease the

electromagnetic immunity of the equipment, wiring or

any connected devices. If in doubt, contact

Flowserve for advice.

The motor must be wired up in

accordance with the motor manufacturer's

instructions (normally supplied within the terminal

box) including any temperature, earth leakage,

current and other protective devices as

appropriate.