MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 20 of 28

flowserve.com

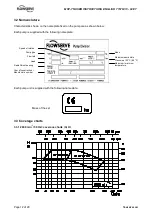

The example (N) value is given for the preferred

operating flow region (typically this may extend to

70 to 120 % of the pump best efficiency point);

outside the preferred flow region the actual

vibration experienced may be multiplied by up to 2.

These standard values can vary with the rotational

speed and the power absorbed by the pump. For

any special case, do not hesitate to consult us.

Measuring vibration at regular intervals will then

show any deterioration in pump or system

operating conditions.

Vibration Velocity - unfiltered

Horizontal

Configuration

mm/s (in./s) r.m.s.

Normal

N

5.6 (0.22)

Alarm

N

x 1.25

7.1 (0.28)

Shutdown Trip

N

x 2.0

11.2 (0.44)

5.5.5 Stop/start frequency

Pump sets are normally suitable for the number of

equally spaced stop/starts per hour shown in the

table below. Check actual capability of the driver

and control/starting system before commissioning.

Motor rating kW (hp)

Maximum stop/starts

per hour

Up to 15 (20)

15

Between 15 (20) and 90 (120)

10

90 (120) to 150 (200)

6

Above 150 (200)

Refer

Where duty and standby pumps are installed it is

recommended that they are run alternately every

week.

5.6 Stopping and shutdown

According to hydraulic conditions of

the installation and its automation degree, stop

and restart procedures can have different forms.

Nevertheless all of them must respect imperatively

the following rules:

5.6.1 Stopping < 1 hour

a) Isolate motor.

b)

Avoid reverse rotation of the pump.

c)

Make sure that the discharge line pressure

does not reach the foot valve.

5.6.2 Stopping < 1 month

a) Isolate motor.

b)

Avoid reverse rotation of the pump.

c)

Make sure that the discharge line pressure

does not reach the foot valve.

d)

Close the outlet valve. Eventually close the

inlet valve.

e) Switch off external power supply,

flushing/quench, cooling liquid.

5.6.3 Shutdown > 1 month

a)

Isolate motor.

b)

Avoid reverse rotation of the pump.

c)

Make sure that the discharge line pressure

does not reach the foot valve.

d)

Close the outlet valve. Eventually close the

inlet valve.

e)

Switch off external power supply,

flushing/quench, cooling liquid.

f)

Keep the pump fully filled with water. In case

of pumped liquid other than water, drain the

pump entirely.

g)

Turn once per week the pump shaft of one or

two turns.

h)

Never restart the pump without carrying out

the verifications recommended before starting

(see § 5.4.1).

When ambient temperatures are

likely to drop below freezing point, the pump and

any cooling and flushing arrangements must be

drained or otherwise protected.

5.6.4 Restarting in continuous running

a)

Ensure that the pump is completely full of

liquid.

b)

Ensure a continuous supply with a sufficient

available NPSH.

c)

Ensure a backpressure so that the motor

power is not in excess.

d)

Respect the starting frequency

imposed by the motor manufacturer.

e)

Protect the pump against water hammer

when stopping or starting.

5.7 Hydraulic, mechanical and

electrical duty

This product has been supplied to meet the

performance specifications of your purchase order,

however it is understood that during the life of the

product these may change. The following notes

may help the user decide how to evaluate the

implications of any change. If in doubt contact your

nearest Flowserve office.

5.7.1 Specific gravity (SG)

Pump capacity and total head in meters (feet) do

not change with SG, however pressure displayed

on a pressure gauge is directly proportional to SG.

Power absorbed is also directly proportional to SG.

It is therefore important to check that any change

in SG will not overload the pump driver or over-

pressurize the pump.

5.7.2 Viscosity

For a given flow rate the total head reduces with

increased viscosity and increases with reduced

viscosity.