MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 21 of 28

flowserve.com

Also for a given flow rate the power absorbed

increases with increased viscosity, and reduces

with reduced viscosity. It is important that checks

are made with your nearest Flowserve office if

changes in viscosity are planned.

5.7.3 Pump speed

Changing pump speed effects flow, total head,

power absorbed, NPSH

R

, noise and vibration.

Flow varies in direct proportion to pump speed,

head varies as speed ratio squared and power

varies as speed ratio cubed. The new duty,

however, will also be dependent on the system

curve.

If increasing the speed, it is important therefore to

ensure the maximum pump working pressure is

not exceeded, the driver is not overloaded, NPSH

A

> NPSH

R

, and that noise and vibration are within

local requirements and regulations.

5.7.4 Net positive suction head (NPSH

A

)

NPSH available (NPSH

A

) is the head available at

the impeller inlet, above the vapor pressure of the

pumped liquid.

NPSH required (NPSH

R

) is the minimum head

required at the impeller inlet, above the vapor

pressure of the pumped liquid, to avoid excessive

cavitation and extreme performance degradation.

It is important that NPSH

A

> NPSH

R

. The margin

between NPSH

A

> NPSH

R

should be as large as

possible.

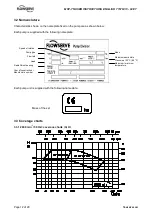

If any change in NPSH

A

is proposed, ensure these

margins are not significantly eroded. Refer to the

pump performance curve to determine exact

requirements particularly if flow has changed.

If in doubt please consult your nearest Flowserve

office for advice and details of the minimum

allowable margin for your application.

5.7.5 Pumped flow

Flow must not fall outside the minimum and

maximum continuous safe flow shown on the

pump performance curve and or data sheet.

5.8 Pumps for Food Use or Potable

Water

If the pump has not been specifically ordered for a

food or drinking water application it must not be

used for these types of applications. If it has been

ordered for this type of application the following

recommendations are to be followed.

5.8.1 Cleaning prior to operation

Pumps that are to be used for a food or drinking

water application should be cleaned before being

put into initial operation and after the installation of

spare parts that are in contact with the liquid.

Cleaning once the pump has been commissioned

will depend on the application and operating

conditions. The user must ensure that the cleaning

procedures are suitable for the application and

operating conditions, and local regulations.

6 MAINTENANCE

6.1 General

If a belt drive is used, the assembly and

tension of the belts must be verified during regular

maintenance procedure.

In dirty or dusty environments, regular checks

must be made and dirt removed from areas around

close clearances, bearing housings and motors.

It is the plant operator's responsibility to

ensure that all maintenance, inspection and

assembly work is carried out by authorized and

qualified personnel who have adequately

familiarized themselves with the subject matter by

studying this manual in detail (see also section

1.6.2).

Any work on the machine must be performed when

it is at a standstill. It is imperative that the

procedure for shutting down the machine is

followed, as described in section 5.6.

On completion of work all guards and safety

devices must be re-installed and made operative

again. Before restarting the machine, the relevant

instructions listed in section 5,

Commissioning,

start up, operation and shut down

must be

observed.

Oil and grease leaks may make the ground

slippery. Machine maintenance must always

begin and finish by cleaning the ground and

the exterior of the machine.

If platforms, stairs and guardrails are required for

maintenance, they must be placed for easy access

to areas where maintenance and inspection are to

be carried out. The positioning of these

accessories must not limit access or hinder the

lifting of the part to be serviced.