MHP-TN USER INSTRUCTIONS ENGLISH 71576313 - 02/07

Page 23 of 28

flowserve.com

If a check shows a bad running of the

motor pump unit, the user must:

a)

Refer to the "fault finding chart" chapter

7 of this leaflet to apply the recommended

solutions.

b)

Ensure that your equipment corresponds to

the arrangements of this leaflet.

c)

Contact Flowserve after-sales Department if

the problem persists.

6.2.4 Gland packing

6.2.4.1 Pump fitted with a packed gland

A well run in and correctly adjusted packing gland

requires little maintenance. If, after some time, the

leakage becomes too great, the gland should be

tightened again in order to return these to a normal

level.

If re-tightening is not possible, new packing must

be installed.

6.2.4.2 Gland packing inspection and removal

a) Remove the shield guards.

b)

Slide back the gland.

c)

Remove the packing rings with an extractor

designed for this purpose (including the

lantern ring if it exists; note its position and its

direction of rotation).

d)

Inspect the state of the sleeve surface; the

presence of many marked grooves will

indicate that it must be replaced.

e) Carefully clean the different pieces of the

packing gland.

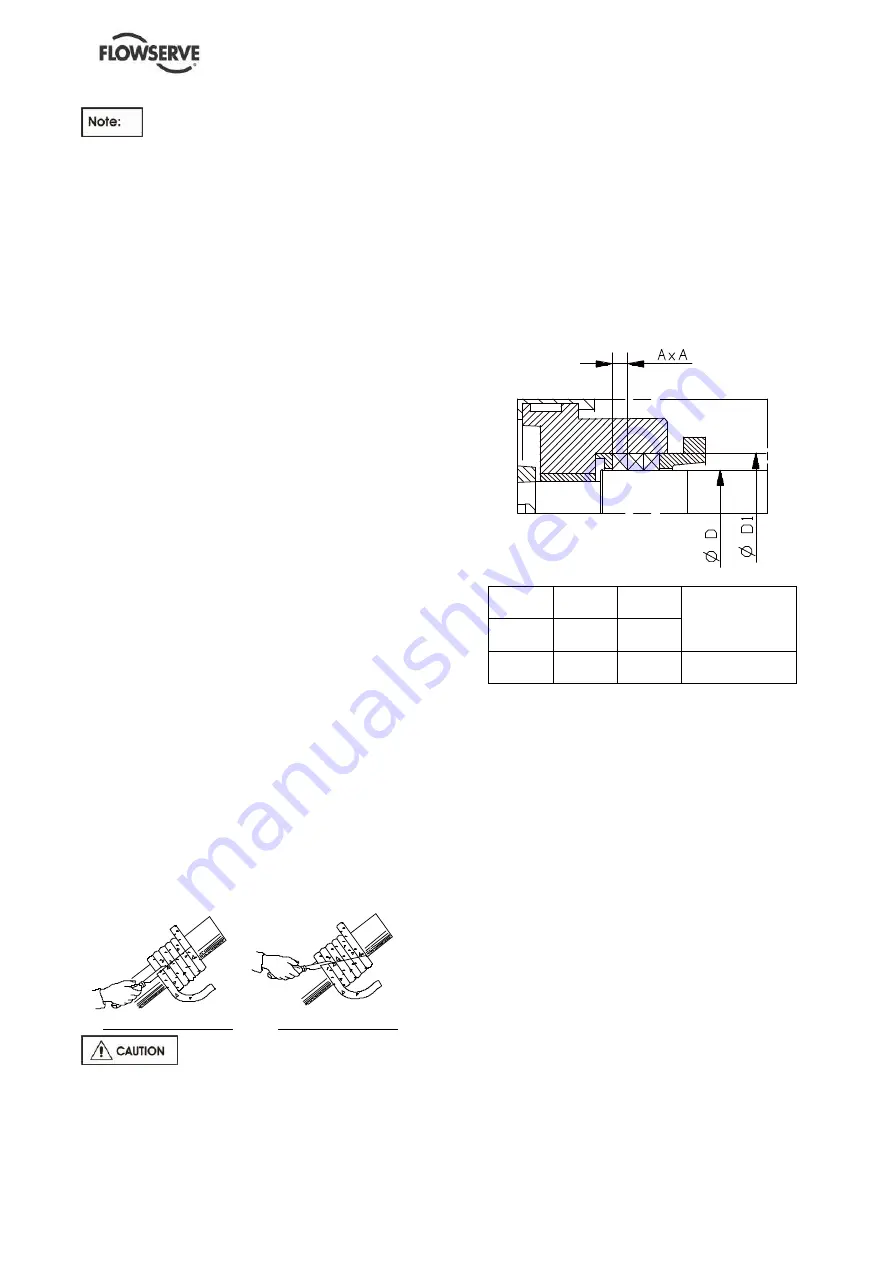

6.2.4.3 Gland packing fitting

If the packing is supplied as cord the packing must

be cut so that the external diameter is lightly

tightened and there is an initial gap between the

sleeve and the packing ring.

For that purpose, wind the packing helically around

the shaft sleeve or a chuck of the same diameter.

(Take precautions to avoid damaging sleeve).

Example of

straight cut

Example of bevel cut

Ensure a tightening on the stuffing

box housing and not on the sleeve.

SETTING OF PACKING

Follow the instructions:

a)

Assemble of the packing in S.

b)

Stagger by about 90° between two rings.

c)

Assemble packing after packing.

After setting the last packing ring, secure the

packing with the gland and tighten the nut by

hand.

After tightening, the shaft should turn by hand as

easily as before the setting of the packing.

D

D1

A x A

mm

(in.)

mm

(in.)

mm

(in.)

Nb x length

in mm

(in.)

55

(2.17)

76

(2.99)

10

(0.39)

4 x 207

(4 x 8.15)

6.2.5 Internal coating

If the pump has an internal coating, this coating

must be inspected periodically. Any wear or cracks

of the coating found must be immediately repaired.

Failure to do this may lead to accelerated wear of

the coating during operation and corrosion of the

exposed base metal, depending on the material

and pumped liquid.

Special attention must be paid to the coating

edges. Any loss of coating material is considered

to be normal wear and tear on the pump and is not

considered as warranty.

Flowserve has applied the coatings according to

the supplier's instructions but will not be held

responsible for coating wear or cracks that may

develop over time.