CPX, CPXR, CPXN and CPXP USER INSTRUCTIONS ENGLISH 71569117 02-10

Page 16 of 44

flowserve.com

A device to provide emergency stopping must

be fitted.

If not supplied pre-wired to the pump unit, the

controller/starter electrical details will also be supplied

within the controller/starter.

For electrical details on pump sets with controllers

see the separate wiring diagram.

See section 5.4, Direction of rotation

before connecting the motor to the electrical supply.

4.9 Protection systems

The following protection systems are

recommended particularly if the pump is installed in a

potentially explosive area or is handling a hazardous

liquid. If in any doubt consult Flowserve.

If there is any possibility of the system allowing the

pump to run against a closed valve or below

minimum continuous safe flow a protection device

should be installed to ensure the temperature of the

liquid does not rise to an unsafe level.

If there are any circumstances in which the system

can allow the pump to run dry, or start up empty, a

power monitor should be fitted to stop the pump or

prevent it from being started. This is particularly

relevant if the pump is handling a flammable liquid.

If leakage of product from the pump or its associated

sealing system can cause a hazard it is

recommended that an appropriate leakage detection

system is installed.

To prevent excessive surface temperatures at

bearings it is recommended that temperature or

vibration monitoring is carried out.

5 COMMISSIONING, START-UP,

OPERATION AND SHUTDOWN

These operations must be carried

out by fully qualified personnel.

5.1 Pre-commissioning procedure

5.1.1 Lubrication

Determine the mode of lubrication of the pump set,

eg grease, oil etc.

For oil lubricated pumps, fill the

bearing housing with correct grade of oil to the

correct level, ie sight glass [3856] or

constant level

oiler bottle [3855].

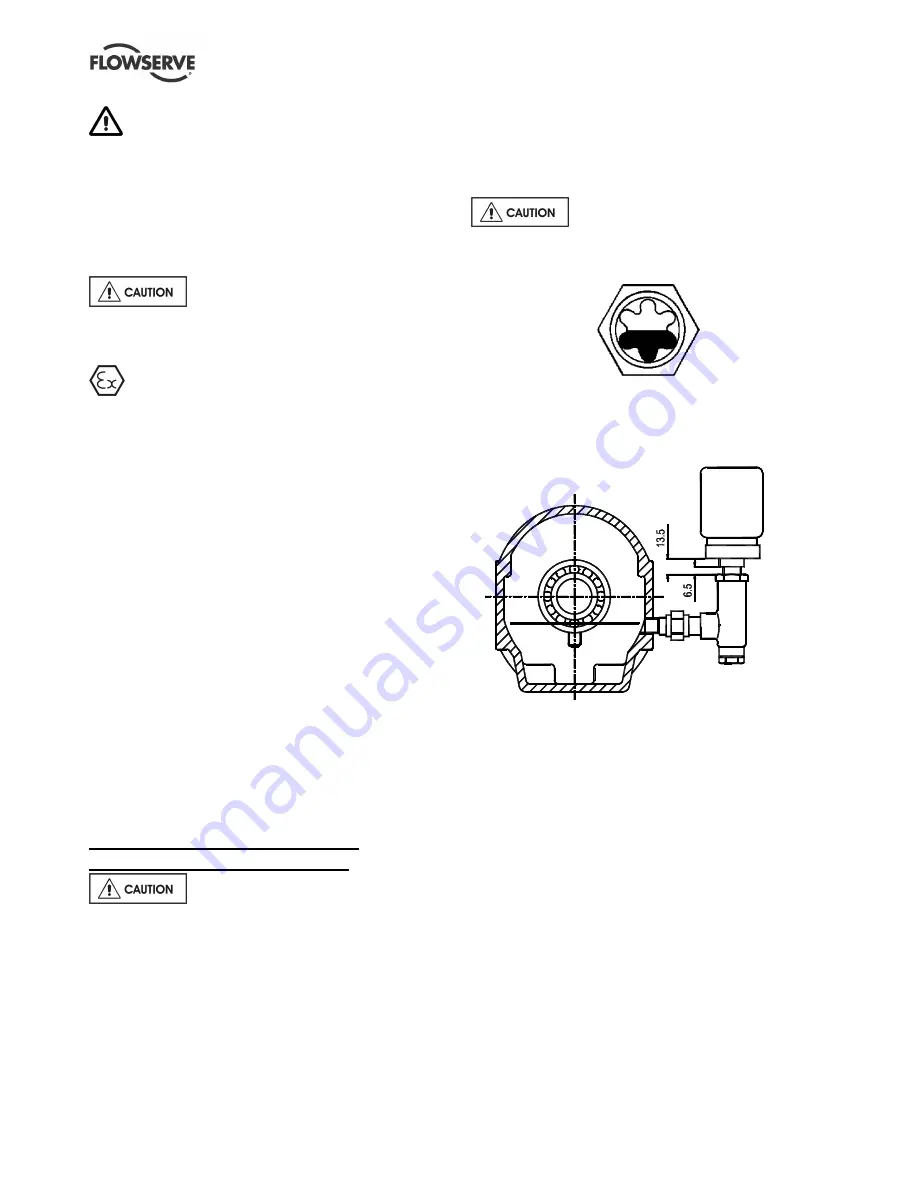

When fitted with a constant level oiler, the bearing

housing should be filled by unscrewing or hinging back

the transparent bottle and filling it with oil. Where an

adjustable body Denco oiler is fitted this should be set to

the height shown in the following diagram:

The oil filled bottle should then be refitted so as to

return it to the upright position. Filling should be

repeated until oil remains visible within the bottle.

Approximate oil volumes are shown in section 5.2.2,

Bearing sizes and capacities.

Grease lubricated pumps and electric motors are

supplied pre-greased.

Where the ambient temperature is very low special

lubricants are required. Where oil lubrication is

utilized and the ambient is less than -5 °C (23 °F)

ensure the oil’s pour point is at least 15 °C (27 ° F)

below the ambient temperature or use oil class SAE

5W-50 or API-SJ and ensure the upper operating

range of the oil is then not exceeded.

Other drivers and gearboxes, if appropriate, should

be lubricated in accordance with their manuals.