CPX, CPXR, CPXN and CPXP USER INSTRUCTIONS ENGLISH 71569117 02-10

Page 27 of 44

flowserve.com

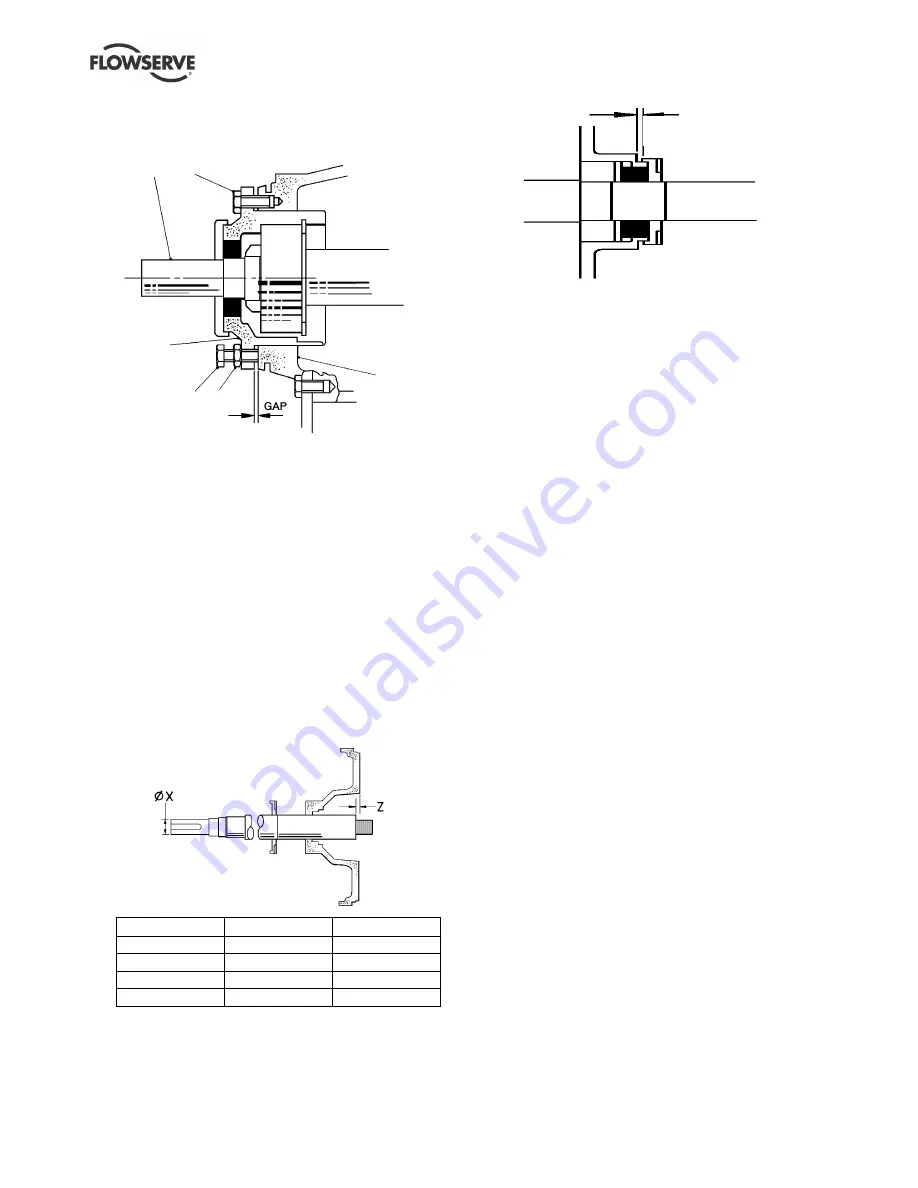

q) Install the shaft assembly into the bearing housing

[3200] until the gap is approximately 5 mm

(0.2 in.).

2100

6570.2

3240

6570.3

6580.1

3200

r) Fit the bearing carrier screws [6570.2] but do not

tighten.

s) Fit the labyrinth ring [4330] (if used) into the

bearing housing ensuring the drain hole faces the

bearing and is at the 6 o'clock position.

t) Press drive side liquid flinger [2540.1] and pump

side liquid flinger [2540.2] onto shaft where

applicable. These should be set 0.5 to 2 mm

(0.02 to 0.08 in.) (light contact for elastomer type)

from the bearing carrier and bearing housing

respectively.

u) The pump side flinger [2540.2] (this feature is

integral with some proprietary labyrinth seals)

should only be set in its final position after setting

the shaft axial position.

v) Temporarily fit the cover [1220]. The shaft [2100]

may now be positioned in relation to the cover

face, as shown below:

Bearing housing

Dia. X mm (in.)

Z mm (in.)

Frame 1

24 (0.945)

9 (0.354)

Frame 2

32 (1.260)

17 (0.669)

Frame 3

42 (1.654)

9 (0.354)

Frame 4

48 (1.890)

22 (0.866)

x) The pump side flinger [2540.2] may then be

moved towards the bearing housing and set with

its clearance.

0.5 to 2 mm

(0.02 to 0.08 in.)

6.10.2 Cover and seal assembly

a) Extreme cleanliness is required. The sealing

faces and shaft or sleeve surface must be free

from scratches or other damage.

b) Refer to section 6.11, Seal arrangements for seal

diagrams.

c) Carefully press the stationary seat into the cover

[1220], ensuring that the seating ring is not

deformed. Where an anti-rotation pin is fitted

ensure that correct engagement with the slot is

achieved.

d) Place any separate seal gland over the shaft.

e) Refer to manufacturer's instructions to position

the mechanical seal rotating elements. Tighten

any drive screws in the seal drive collar. For

precise compression most cartridge seals should

be set after complete pump assembly.

f) Fit the cover [1220] into the bearing housing

[3200] and tighten all fasteners.

6.10.3 Gland packing assembly

a) Assemble the gland packing [4130] into the cover

[1220] before fitting on to the shaft [2100].

b) Stagger the joints in the gland packing by 90

degrees to each other.

c) The lantern ring halves [4134], if required, should

be positioned mid-way along the packing.

d) Position the gland [4120] squarely against the last

ring and tighten the gland nuts finger-tight only.

Install into bearing housing assembly and fit the

two screws to hold the cover in place.

e) Check that the shaft rotates freely.