CPX, CPXR, CPXN and CPXP USER INSTRUCTIONS ENGLISH 71569117 02-10

Page 9 of 44

flowserve.com

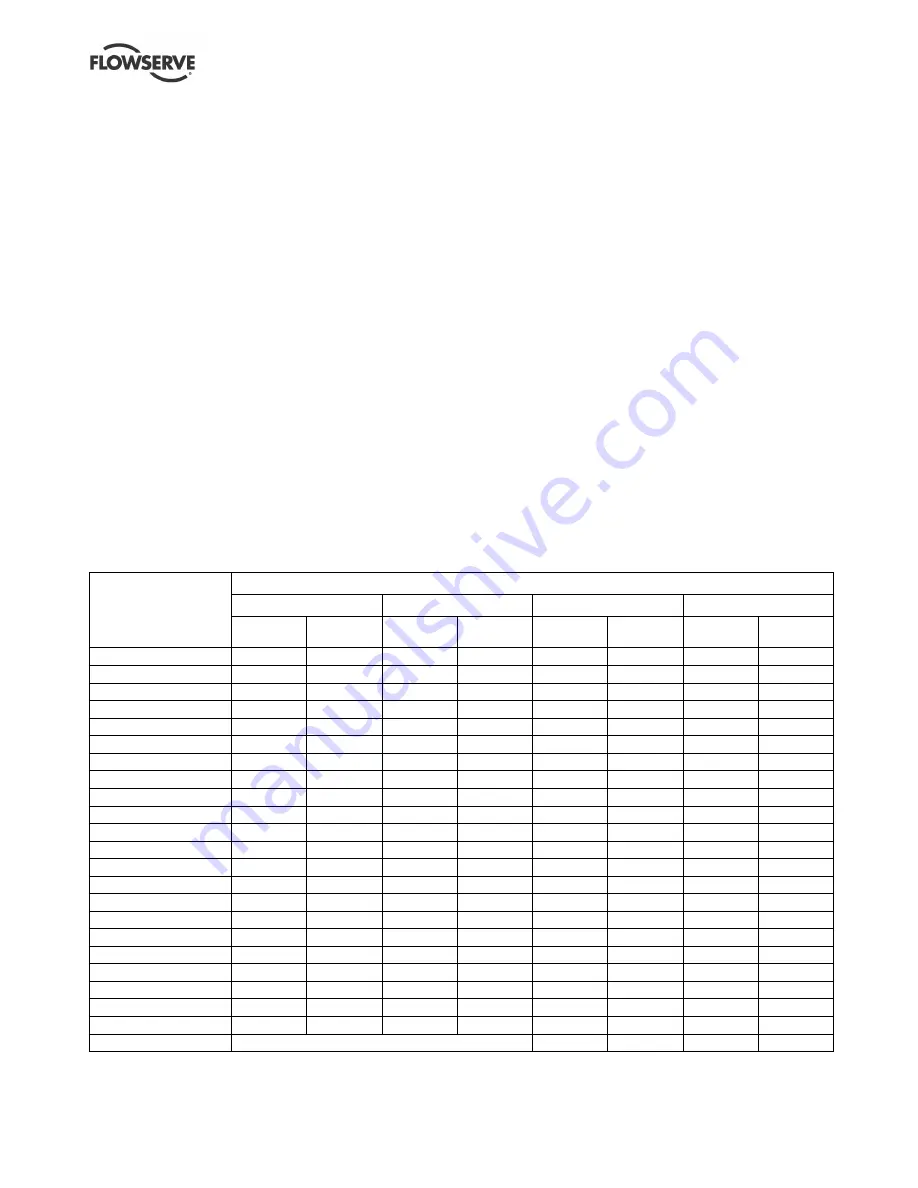

1.8 Specific machine performance

For performance parameters see section 1.5, Duty

conditions. Where performance data has been supplied

separately to the purchaser these should be obtained

and retained with these User Instructions.

1.9 Noise level

Attention must be given to the exposure of personnel

to the noise, and local legislation will define when

guidance to personnel on noise limitation is required,

and when noise exposure reduction is mandatory.

This is typically 80 to 85 dBA.

The usual approach is to control the exposure time to

the noise or to enclose the machine to reduce emitted

sound. You may have already specified a limiting

noise level when the equipment was ordered,

however if no noise requirements were defined, then

attention is drawn to the following table to give an

indication of equipment noise level so that you can

take the appropriate action in your plant.

Pump noise level is dependent on a number of

operational factors, flow rate, pipework design and

acoustic characteristics of the building, and so the

values given are subject to a 3 dBA tolerance and

cannot be guaranteed.

Similarly the motor noise assumed in the “pump and

motor” noise is that typically expected from standard

and high efficiency motors when on load directly driving

the pump. Note that a motor driven by an inverter may

show an increased noise at some speeds.

If a pump unit only has been purchased for fitting with

your own driver then the “pump only” noise levels in the

table should be combined with the level for the driver

obtained from the supplier. Consult Flowserve or a

noise specialist if assistance is required in combining

the values.

It is recommended that where exposure approaches

the prescribed limit, then site noise measurements

should be made.

The values are in sound pressure level L

pA

at 1 m

(3.3 ft) from the machine, for “free field conditions

over a reflecting plane”.

For estimating sound power level L

WA

(re 1 pW) then

add 14 dBA to the sound pressure value.

Typical sound pressure level L

pA

at 1 m reference 20

µ

Pa, dBA

3 550 r/min

2 900 r/min

1 750 r/min

1 450 r/min

Motor size

and speed

kW (hp)

Pump

only

Pump and

motor

Pump

only

Pump and

motor

Pump

only

Pump and

motor

Pump

only

Pump and

motor

<0.55(<0.75)

72

72

64

65

62

64

62

64

0.75 (1)

72

72

64

66

62

64

62

64

1.1 (1.5)

74

74

66

67

64

64

62

63

1.5 (2)

74

74

66

71

64

64

62

63

2.2 (3)

75

76

68

72

65

66

63

64

3 (4)

75

76

70

73

65

66

63

64

4 (5)

75

76

71

73

65

66

63

64

5.5 (7.5)

76

77

72

75

66

67

64

65

7.5 (10)

76

77

72

75

66

67

64

65

11(15)

80

81

76

78

70

71

68

69

15 (20)

80

81

76

78

70

71

68

69

18.5 (25)

81

81

77

78

71

71

69

71

22 (30)

81

81

77

79

71

71

69

71

30 (40)

83

83

79

81

73

73

71

73

37 (50)

83

83

79

81

73

73

71

73

45 (60)

86

86

82

84

76

76

74

76

55 (75)

86

86

82

84

76

76

74

76

75 (100)

87

87

83

85

77

77

75

77

90 (120)

87

88

83

85

77

78

75

78

110 (150)

89

90

85

87

79

80

77

80

150 (200)

89

90

85

87

79

80

77

80

200 (270)

1

1

1

1

85

87

83

85

300 (400)

–

87

90

85

86

1

The noise level of machines in this range will most likely be of values which require noise exposure control, but typical values are inappropriate.

Note: for 1 180 and 960 r/min reduce 1 450 r/min values by 2 dBA. For 880 and 720 r/min reduce 1 450 r/min values by 3 dBA.