DMX/DMXD/DMXH/DMXDH USER INSTRUCTIONS ENGLISH 71569282 - 10/09

Page 39 of 60

i)

Continue to disassemble the impellers by

repeating steps c) and d) until all impellers [2200]

have been removed from the shaft.

In case of double suction pump (DMXD and

DMXDH), remove crossover sleeve [2450] after the

first stage impeller is removed by applying heat.

6.6.9

Impeller ring removal

Remove impeller rings by removing the set-screws

[6570] and machine off.

6.6.10 Parting flange gasket

Remove all traces of old gasket [4590] material.

When using any tool to surfaces remove gasket

material, do not gouge machined surfaces. Do not

reuse the gasket once the casing is opened. Use only

Flowserve recommended replacement materials.

6.7 Examination of parts

6.7.1

Inspection and renewal of parts

a) Having completely dismantled the rotor, check

the shaft for runout using "V" blocks or rollers

placed under the normal running areas. Runout

not to exceed 0.050 mm (0.002 in.) TIR.

b) Wire-brush the pump parts thoroughly. Clean off

all scale, carbon etc. Examine parts for wearing

corrosion and erosion.

c) Check throttling sleeve, center sleeve and

crossover sleeve (if supplied) for wear. Replace if

required.

d) The casing ring/impeller rings are renewable and

should be replaced when badly grooved, and/or

when the pump performance does not meet the

system requirements. Whenever it becomes

necessary to replace either wearing ring, both

rings involved (casing ring and impeller ring)

must be ordered and replaced as they are

furnished standard size only.

If new casing rings are used, make sure that they

seat in both the upper and lower half casing and

that the anti-rotation device is properly located in

its respective lower half casing fit. The use of a

scraper on the ring to casing fit will help to fit the

ring to the casing.

e) Using a torch could change the metallurgy of the

rings if too much heat is applied. Removing

impellers with torch is acceptable but putting on

new impeller rings shall be done with oven

instead of torch.

6.7.2

Dynamic-balance impeller

Whenever an impeller is tampered with, (i.e. new

impeller, wear rings installed etc.) the impeller must

be dynamically balanced before being reassembled

to shaft.

Dynamic balance shall be performed on a suitable

balancing machine by trained personnel.

Two balance planes shall be used and located

equidistance as possible from the center of gravity of

the impeller.

The maximum allowable unbalance at each of the

two planes shall be calculated as follows:

U =4 W / N or .01 oz-in whichever is greater.

U = Unbalance per plane oz-in

W = Impeller weight per plane lb.

Usually 1/2 the total impeller weight.

N = Operational rotational speed RPM

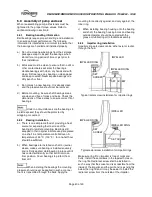

Metal shall be removed from the impeller shrouds

during the balancing operation in accordance with the

attached sketches until the impeller is within

acceptable tolerance limit of unbalance.

Grinding impeller for dynamic-balance

Grinding must not be performed in the area within

19mm (¾") of the final diameter of the impeller.

Grinded area’s shall have a smooth transition to the

not grinded areas and shall be polished. Minimum

thickness of impeller shrouds after balancing may not

be less than 80% of the nominal thickness per detail

drawing.

POINT OF

UNBALANCE

GROUND

AREA