DMX/DMXD/DMXH/DMXDH USER INSTRUCTIONS ENGLISH 71569282 - 10/09

Page 40 of 60

6.8 Assembly of pump and seal

When reassembling pump, all fasteners must be

tightened to the proper torque values. Refer to

sectional drawing

in section 8

.

6.8.1

Bearing handling information

Ball bearings require proper handling and installation

to ensure optimum performance. The following

information is intended as a minimum to ensure that

the bearings are handled and installed properly.

a) Do not remove new bearings from their storage

package except to inspect the bearings, when

stored for a long period of time or just prior to

their installation.

b) Work area must be clean to ensure that no dirt or

other contaminates will enter the bearings.

Handle bearings with clean, dry hands and with

clean, lint free rags. Lay bearing on clean paper

and keep covered. Never expose bearings on a

dirty bench or floor.

c) Do not wash a new bearing. It is already clean

and the preservative should not be removed.

d) Before mounting, be sure shaft bearings areas

are clean and free of nicks and burrs. Check the

dimensions of these areas to ensure correct fit of

bearings.

Under no circumstances are the bearings to

be left exposed; they should be protected by

wrapping or covered.

6.8.2

Bearing installation

a) There is one simple method of providing a heat

source for expanding the inner race of the

bearings to facilitate mounting. Bearings still

wrapped in their original intimate wrap are placed

on a shelf in a temperature-controlled oven. A

temperature of 66 °C. (150 °F.) for one-half hour

should be sufficient.

b) When bearings are installed on shaft or journal

sleeve, make sure bearing is installed squarely

and is firmly seated. Hold bearing in place until it

has cooled sufficiently so that it will not move

from position. Cover bearings to protect them

from dirt.

When installing the bearings the mounting

pressure should never be applied in such a manner

that it is transmitted through the balls. Apply the

mounting force directly against, and only against, the

inner ring.

c) When installing bearing housing onto the bearing

and shaft, the bearing housing bores and bearing

outside diameter should be coated with the

grease or lubricating oil to facilitate assembly.

6.8.3

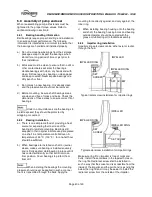

Impeller ring installation

Impellers ring setscrews can be either axial or radial

through the hub.

Typical radial screw installation for impeller rings.

Typical axial screw installation for impeller rings.

Make sure ring fit on impeller is free of nicks and

burrs. Install the set-screws in the tapered holes on

the ring fits. Radial set screw shall be installed in

such a way that the socket end is accessible from the

inside of the impeller and the point end is just slightly

below the ring fit land. It may be easier to install the

radial set screw from the outside of the impeller.

IMPELLER

IMPELLER RING

SET

SCREW

SET SCREW

IMPELLER RING

IMPELLER RING

SET SCREW

SET

SCREW

IMPELLER

IMPELLER RING