DMX/DMXD/DMXH/DMXD

DMX/DMXD/DMXH/DMXDH

H USER

USER INSTRUCTIONS

INSTRUCTIONS ENGLISH

ENGLISH 71569282

71569282 -

- 10/09

10/09

Page 18 of 60

Page 18 of 60

this may result in permanent deformation of

this may result in permanent deformation of

baseplate.

baseplate.

Pump, driver auxiliary equipment and

Pump, driver auxiliary equipment and

piping shall be removed from the baseplate before

piping shall be removed from the baseplate before

leveling the baseplate.

leveling the baseplate.

Locate the baseplate in its proper position on the

Locate the baseplate in its proper position on the

concrete block together with the leveling screws as

concrete block together with the leveling screws as

shown in the General Arrangement Drawing.

shown in the General Arrangement Drawing.

Using a precision level across the machined surfaces

Using a precision level across the machined surfaces

of the pump and driver mounting pads, adjust leveling

of the pump and driver mounting pads, adjust leveling

screws as necessary to ensure that baseplate is

screws as necessary to ensure that baseplate is

leveled in all directions.

leveled in all directions.

When the baseplate is leveled, snug the foundation

When the baseplate is leveled, snug the foundation

bolts, but do not completely tighten.

bolts, but do not completely tighten.

4.2.3

4.2.3

Preliminary

Preliminary alignment

alignment

Using the previous procedure, adjust baseplate until

Using the previous procedure, adjust baseplate until

pump and driver are within 0.076 mm (0.003 in.).

pump and driver are within 0.076 mm (0.003 in.).

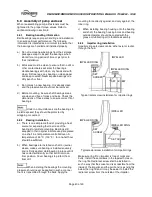

4.3 Grouting

4.3 Grouting

The following information regarding

The following information regarding

grouting is only offered as a general guideline.

grouting is only offered as a general guideline.

Flowserve requires that all grouting be installed in

Flowserve requires that all grouting be installed in

accordance with specifications set forth in Chapter 5,

accordance with specifications set forth in Chapter 5,

Mounting Plate Grouting

Mounting Plate Grouting

from API Recommended

from API Recommended

Practices 686/PIP REIE 686, First Edition

Practices 686/PIP REIE 686, First Edition

..

Refer to

Refer to

API 610 - Eighth Edition - Appendix `L`

API 610 - Eighth Edition - Appendix `L`

for baseplate

for baseplate

grouting requirements. It is recommended that the

grouting requirements. It is recommended that the

customer consult a competent specialist skilled in the

customer consult a competent specialist skilled in the

field of grouting, to insure the proper installation of all

field of grouting, to insure the proper installation of all

grouting.

grouting.

The following ASTM Specifications are furnished as

The following ASTM Specifications are furnished as

references for test methods used in conjunction with

references for test methods used in conjunction with

installation of grouting materials and should be used

installation of grouting materials and should be used

to obtain proper results:

to obtain proper results:

ASTM C 78-84,

ASTM C 78-84,

Test Method for Flexural Strength for

Test Method for Flexural Strength for

Concrete

Concrete

ASTM C 109-90,

ASTM C 109-90,

Test Method for Compressive

Test Method for Compressive

Strength of Hydraulic Cement Mortars – Modified

Strength of Hydraulic Cement Mortars – Modified

ASTM C 469-87a,

ASTM C 469-87a,

Test Method for Static Modulus of

Test Method for Static Modulus of

Elasticity and Poisson’s Ratio of Concrete in

Elasticity and Poisson’s Ratio of Concrete in

Compression

Compression

ASTM C 496-90,

ASTM C 496-90,

Test Method for Splitting Tensile

Test Method for Splitting Tensile

Strength of Cylindrical Concrete Specimens

Strength of Cylindrical Concrete Specimens

ASTM C 531-85,

ASTM C 531-85,

Test Method for Linear Shrinkage

Test Method for Linear Shrinkage

and Coefficient of Thermal Expansion of Chemical

and Coefficient of Thermal Expansion of Chemical

Resistant Grouts and Monolithic Surfacing - Modified

Resistant Grouts and Monolithic Surfacing - Modified

ASTM C 666-90,

ASTM C 666-90,

Test Method for Resistance of

Test Method for Resistance of

Concrete to Rapid Freezing and Thawing

Concrete to Rapid Freezing and Thawing

ASTM C 939-87,

ASTM C 939-87,

Test Method for Flow of Grout for

Test Method for Flow of Grout for

Preplaced Aggregate Concrete (Flow Cone Method)

Preplaced Aggregate Concrete (Flow Cone Method)

ASTM C 942-86,

ASTM C 942-86,

Test Method for Compressive

Test Method for Compressive

Strength of Grouts for Preplaced Aggregate Concrete

Strength of Grouts for Preplaced Aggregate Concrete

in the Laboratory

in the Laboratory

ASTM C 1090-88,

ASTM C 1090-88,

Test Method for Measuring

Test Method for Measuring

Changes in Height of Cylindrical Specimens from

Changes in Height of Cylindrical Specimens from

Hydraulic Cement Grout

Hydraulic Cement Grout

ASTM C 1107-91,

ASTM C 1107-91,

Standard Specification for

Standard Specification for

Packaged Hydraulic-Cement Grout (Non-Shrink)

Packaged Hydraulic-Cement Grout (Non-Shrink)

(CRD-C 621-92), ACI 351,

(CRD-C 621-92), ACI 351,

Grouting for Support of

Grouting for Support of

Equipment and Machinery

Equipment and Machinery

24-Hour Test,

24-Hour Test,

MBT Test Method for Grout

MBT Test Method for Grout

Performance

Performance

Minimum requirements for epoxy grout

Minimum requirements for epoxy grout

(typical properties at 23

(typical properties at 23

o

o

C (73

C (73

o

o

F))

F))

ASTM D-635,

ASTM D-635,

Fire Resistant

Fire Resistant

ASTM C-579B,

ASTM C-579B,

Minimum Compressive Strength –

Minimum Compressive Strength –

12000 psi

12000 psi

ASTM C-827,

ASTM C-827,

Height Change @ 38

Height Change @ 38

o

o

C (100

C (100

o

o

F) –

F) –

Positive – Effective Bearing Area – 95%

Positive – Effective Bearing Area – 95%

ASTM C-1181,

ASTM C-1181,

Maximum Creep in 1 Year –

Maximum Creep in 1 Year –

1.6X10

1.6X10

-3

-3

in./in. at 140

in./in. at 140

o

o

F, 400 psi

F, 400 psi

ASTM C-307,

ASTM C-307,

Minimum Tensile Strength – 12.4 Mpa

Minimum Tensile Strength – 12.4 Mpa

(1800 psi)

(1800 psi)

ASTM C-580,

ASTM C-580,

Minimum Flexural Strength – 26.2 Mpa

Minimum Flexural Strength – 26.2 Mpa

(3800 psi)

(3800 psi)

ASTM C-580,

ASTM C-580,

Minimum Flexural Secant Modulus –

Minimum Flexural Secant Modulus –

1.2X10

1.2X10

4

4

Mpa (1.8X10

Mpa (1.8X10

6

6

psi)

psi)

ASTM C-531,

ASTM C-531,

Maximum Coefficient of Expansion –

Maximum Coefficient of Expansion –

17X10

17X10

-6

-6

in./in./

in./in./

o

o

F

F

..

Maximum Peak Exotherm 1000 g

Maximum Peak Exotherm 1000 g

(35.27 oz.) insulated – 35

(35.27 oz.) insulated – 35

o

o

C (95

C (95

o

o

F). Full Aggregate

F). Full Aggregate

Must Be Used.

Must Be Used.