DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 22 of 52

flowserve.com

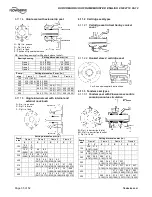

5.2 Pump lubricants

5.2.1

Recommended oil lubricants

C

e

n

tr

if

u

g

a

l

p

u

m

p

lu

b

ri

c

a

ti

o

n

Oil

Splash / force feed / purge oil mist/ pure oil mist lubrication

Viscosity cSt

@ 40 ºC

32

46

68

Oil temperature range *

-5 to 65 ºC

(23 to 149 ºF)

-5 to 78 ºC

(23 to 172 ºF)

-5 to 80 ºC

(23 to 176 ºF)

Designation to ISO 3448

and DIN51524 part 2

ISO VG 32

32 HLP

ISO VG 46

46 HLP

ISO VG 68

68 HLP

O

il

c

o

m

p

a

n

ie

s

a

n

d

lu

b

ri

c

a

n

ts

BP Castrol

†

Energol HLP-HM 32

Energol HLP-HM 46

Energol HLP-HM 68

ELF/Total

†

ELFOLNA DS 32

Azolla ZS 32

ELFOLNA DS 46

Azolla ZS 46

ELFOLNA DS 68

Azolla ZS 68

LSC (for oil mist) **

LSO 32 (Synthetic oil)

LSO 46 (Synthetic oil)

LSO 68 (Synthetic oil)

ExxonMobil

†

Mobil DTE 24

Mobil DTE Light

Mobil DTE 25

Mobil DTE Medium

Mobil DTE 26

Mobil DTE Heavy Medium

Q8

†

Q8 Haydn 32

Q8 Haydn 46

Q8 Haydn 68

Shell

†

Shell Tellus 32

Shell Tellus 46

Shell Tellus 68

Chevron Texaco

†

Rando HDZ 32

Rando HDZ 46

Rando HDZ 68

Wintershall (BASF Group)

†

Wiolan HS32

Wiolan HS46

Wiolan HS68

Fuchs

†

Renolin B 10

Renolin B 15

Renolin B 20

* Note that it normally takes 2 hours for bearing temperature to stabilize and the final temperature will depend on the ambient, r/min,

pumpage temperature and pump size. Also some oils have a greater viscosity index than the minimum acceptable of 95 which may

extend the minimum temperature capability of the oil. Always check the grade capability where the ambient is less than -5 ºC (23 ºF).

†

Use LSC for oil mist. Oil parameters provide flash point >166 ºC (331 ºF), density >0.87 @ 15 ºC (59 ºF), pour point of -10 ºC (14 ºF) or

lower.

**

Normal compounded oils CANNOT be used with oil mist as anti-foam additives need to be avoided. Most oils recommended for

wet splash lubrication contain foam inhibitors as well as antioxidants and anticorrosion additives, so they are unsuitable for oil mist.

Some synthetic lubricants may attack the Nitrile seals used in a regular bearing housing. The LSC LSO oils are recommended for

oil mist applications. We recommend using Royal Purple SYNFILM in one of the above ISO VG designations if synthetic oil is

required for splash bath lubrication to avoid changing to Viton seals in the bearing housing. It is available in the EU from Renox

S.N.C., Via Bologna 12, 60019 Senigallia (ANOCONA), Italy.

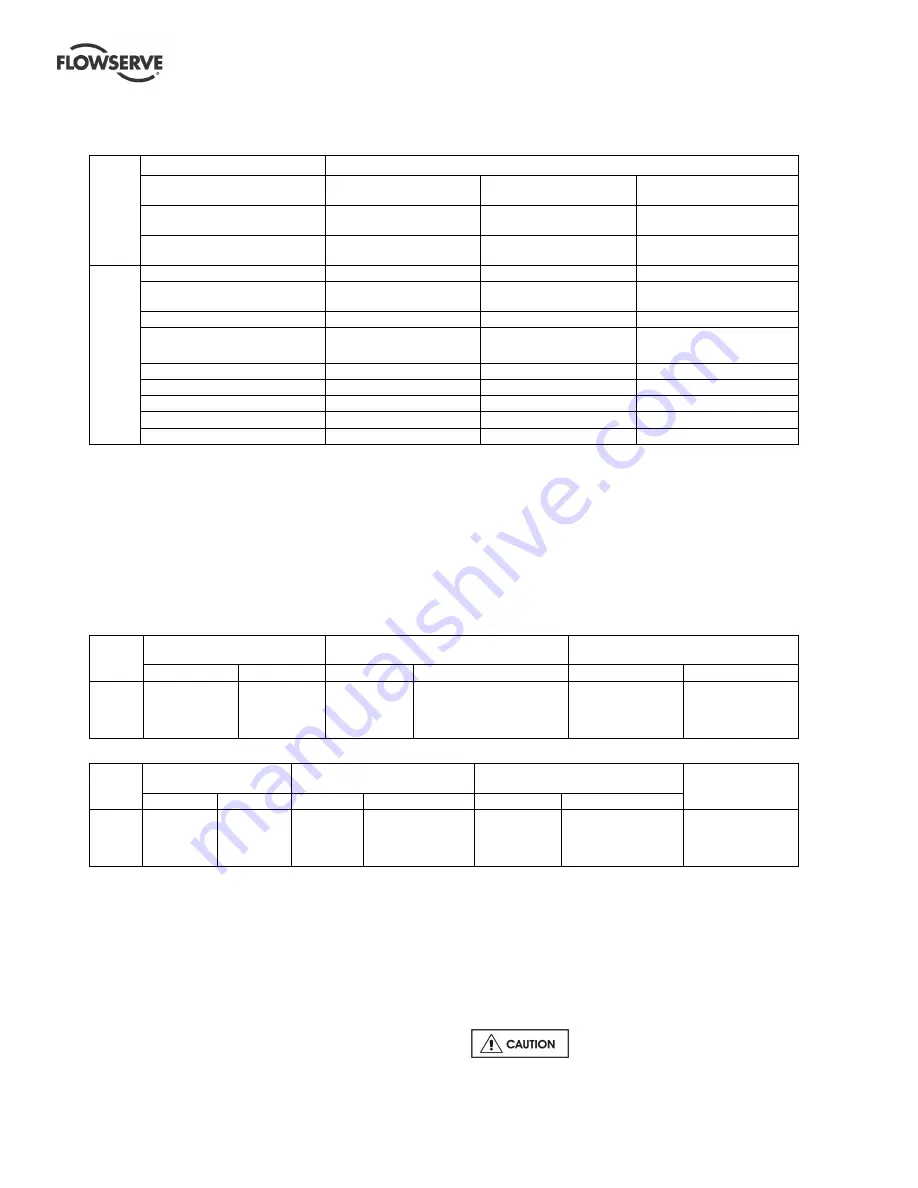

5.2.2

Bearing sizes and capacities

Frame

size

Grease lubricated

medium duty bearings

Grease lubricated

heavy duty bearings

Grease lubricated bearing capacities

g (oz.)

Pump end

Drive end

Pump end

Drive end *

Pump end

Drive end

1

2

3

4

6207 Z C3

6309 Z C3

6311 Z C3

6313 Z C3

3306 Z C3

3309 Z C3

3311 Z C3

3313 Z C3

6207 Z C3

6309 Z C3

6311 Z C3

6313 Z C3

7306 pair back-to-back

7309 pair back-to-back

7311 pair back-to-back

7313 pair back-to-back

6 (0.2.)

13 (0.5)

18 (0.6)

20 (0.7)

14 (0.5)

25 (0.9)

35 (1.2)

46 (1.6)

* Nilos ring fitted into bearing locknut [3712.2]

Frame

size

Oil lubricated

medium duty bearings

Oil lubricated

heavy duty bearings

Oil lubricated optional

heavy duty bearings

Frame oil capacity

(approx.)*

litre (fl.oz)

Pump end

Drive end

Pump end

Drive end

Pump end

Drive end

1

2

3

4

6207 C3

6309 C3

6311 C3

6313 C3

3306 C3

3309 C3

3311 C3

3313 C3

6207 C3

6309 C3

6311 C3

6313 C3

7306 back-to-back

7309 back-to-back

7311 back-to-back

7313 back-to-back

NUP 207 C3

NUP 309 C3

NUP 311 C3

NUP 313 C3

7306 back-to-back

7309 back-to-back

7311 back-to-back

7313 back-to-back

0.5 (17)

1.0 (34)

0.8 (27)

1.6 (54)

Note: the bearing sizes do not constitute a purchasing specification.

* Sump volume only, does not include the oil in the constant level oiler.

5.2.3

Recommended grease lubricants

NLGI grade 2 is generally advised for horizontal bearing

housings and NLGI 3 where the bearing housing is

used vertically. The bearings are pre-greased. The

NLGI 2 grade fitted in the factory with grease nipples is

Mobil Polyrex EM grease which has a Polyurea soap

incorporating a mineral oil. NLGI 3 grade is

recommended for vertical applications, if vertical

orientation was specified with order, then the NLGI 3

grease fitted in the factory for vertical application is

Mobil Polyrex EM103 grease or equivalent which has a

Polyurea soap incorporating a mineral oil. These

greases are suitable for high bearing and ambient

temperatures and ambient down to at least -20 °C.

Below this ambient, specialist greases may be required

and Shell Aeroshell 22 is normally required for the

minimum ambient down to nitrile limitation of -45 °C.

Different types or grades of greases

must never be mixed.

Summary of Contents for Durco Mark 3

Page 49: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 49 of 52 flowserve com Notes ...

Page 50: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 50 of 52 flowserve com Notes ...

Page 51: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 51 of 52 flowserve com Notes ...