DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 23 of 52

flowserve.com

Food grade grease, when applicable:

5.2.3.1

NSF H1 Klubersynth UH1 64-62 is the food grade

grease option and it is NLGI grade 2.

5.2.4

Recommended fill quantities

Refer to section 5.2.2, Bearing sizes and capacities.

5.2.5

Lubrication schedule

Refer to section 6.2.3

5.3 Impeller clearance

The impeller clearance is set in the factory. The

clearance may require adjustment because of high

liquid temperature. If piping attachment alter the

impeller clearance then correct piping. For setting

instructions see section 6.7, Setting impeller

clearance.

5.4 Direction of rotation

Serious damage can result if the pump

is started or run in the wrong direction of rotation.

The pump is shipped with the coupling element

removed. Ensure the direction of rotation of the motor is

correct before fitting the coupling element. Direction of

rotation must correspond to the direction arrow.

If maintenance work has been carried

out to the site's electricity supply, the direction of

rotation should be re-checked as above in case the

supply phasing has been altered.

5.5 Guarding

Guarding is supplied fitted to the pump set.

In member countries of the EU and EFTA, it is a legal

requirement that fasteners for guards must remain

captive in the guard to comply with the Machinery

Directive 2006/42/EC. When releasing such guards,

the fasteners must be unscrewed in an appropriate

way to ensure that the fasteners remain captive.

Whenever guarding is removed or disturbed ensure

that all the protective guards are securely refitted

prior to start-up.

5.6 Priming and auxiliary supplies

5.6.1

Filling and priming, non self primer casing

Ensure inlet pipe and pump casing is

completely full of liquid before starting continuous

duty operation.

Priming may be carried out with an ejector, vacuum

pump, interceptor or other equipment, or by flooding

from the inlet source.

When in service, pumps using inlet pipes with foot

valves may be primed by passing liquid back from the

outlet pipe through the pump.

5.6.2

Filling and priming, self priming casing

Fill the pump with liquid to be pumped,

or compatible liquid, via the filling hole, before starting

continuous duty operation.

The pump has self-priming action for which a separate

air pump is not normally required.

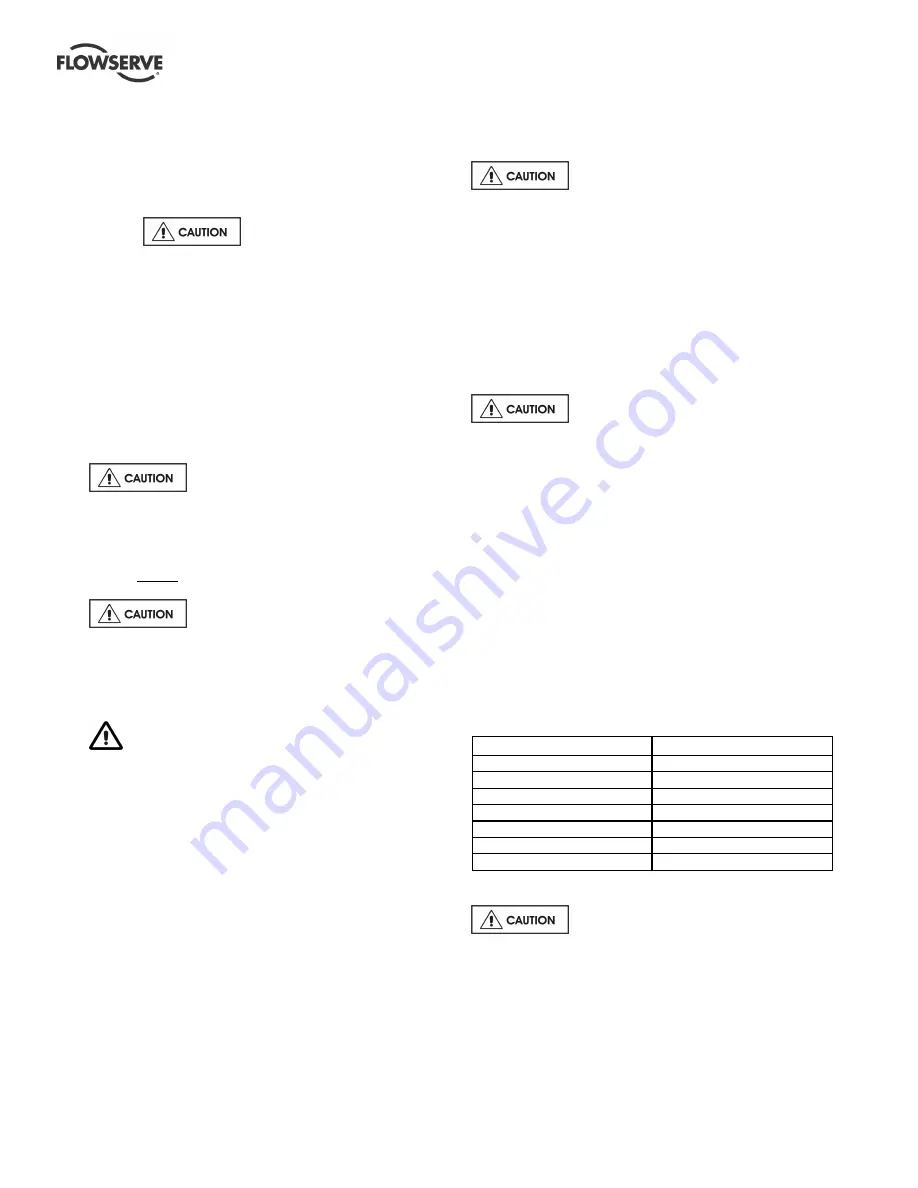

Pump housing

filling hole.

When the initial fill

reaches the suction

pipe, excess liquid will

flow out of the casing.

Pump size

Initial fill litre (US gal.)

40-40-125

2.5 (0.65)

80-80-125

6.0 (1.60)

40-40-160

3.0 (0.80)

80-80-160

6.5 (1.75)

40-40-200

5.0 (1.30)

65-65-200

8.5 (2.25)

80-80-250

12.0 (3.20)

5.6.3

Auxiliary supplies

Ensure all electrical, hydraulic,

pneumatic, sealant and lubrication systems (as

applicable) are connected and operational.

Summary of Contents for Durco Mark 3

Page 49: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 49 of 52 flowserve com Notes ...

Page 50: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 50 of 52 flowserve com Notes ...

Page 51: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 51 of 52 flowserve com Notes ...