DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06-12

Page 30 of 52

flowserve.com

c) Rotating the bearing carrier [3240] the width of one of

the indicator patterns cast into the bearing carrier

moves the impeller [2200] axially 0.1 mm (0.004 in.).

Example: for an impeller setting of 0.4 mm (0.016 in.)

simply move the bearing carrier clockwise four

indicator patterns for the required clearance.

d) Use the indicator pattern closest to the top centre

of the bearing housing as the reference point to

begin adjustment.

e) After obtaining the proper clearance, listed in the

table above, tighten the set-screws [6570.1] evenly

to lock the impeller [2200] and shaft [2100]

assembly. Tightening the screws [6570.1] will

cause the impeller to move 0.05 mm (0.002 in.)

closer to the rear cover because of the internal

clearance in the bearing carrier threads. This must

be considered when setting the impeller clearance.

f) If a cartridge seal [4200] is fitted it should be

reset at this point.

g) Check that the shaft can turn freely without

binding.

h) Ensure the coupling distance between shaft ends

(DBSE) is correct. Reset/re-align if necessary.

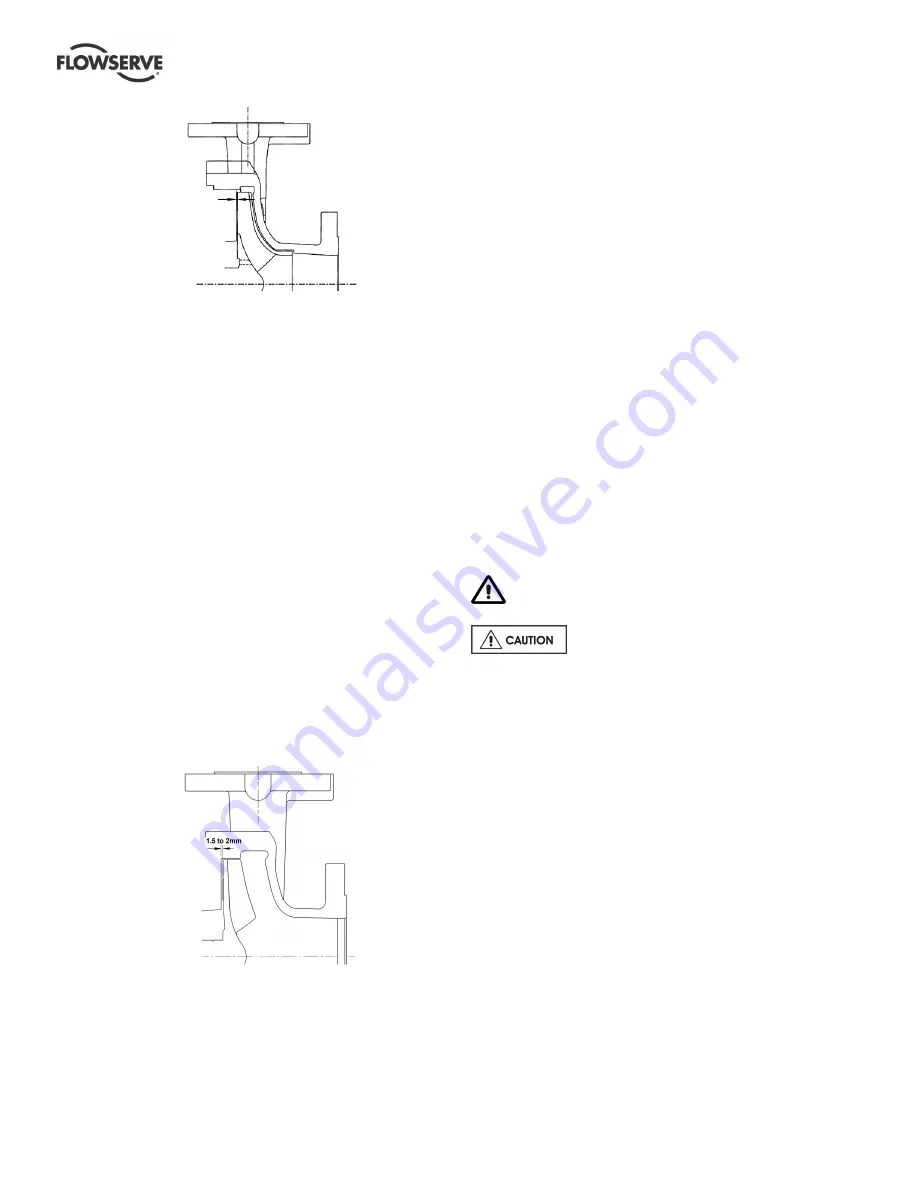

6.7.3

Setting recessed impeller rear clearance

a) Recessed open impellers are set off the cover.

This allows the impeller to be set without the casing.

b) Turn the bearing carrier [3240] counter-clockwise

until the impeller [2200] comes into light contact

with the cover [1220]. Rotating the shaft [2100]

at the same time will accurately determine when

a detectable rub is obtained. This is the zero

clearance setting.

c) Rotating the bearing carrier [3240] the width of one of

the indicator patterns cast into the bearing carrier

moves the impeller [2200] axially 0.1 mm (0.004 in.).

Example: for an impeller setting of 1.5 mm (0.059 in.)

simply move the bearing carrier clockwise fifteen

indicator patterns for the required clearance.

d) Use the indicator pattern closest to the top centre

of the bearing housing as the reference point to

begin adjustment.

e) After obtaining the proper clearance of 1.5 mm

(0.059 in.) to 2 mm (0.079 in.), tighten the set-

screws [6570.1/2] evenly to lock the impeller

[2200] and shaft [2100] assembly. Tightening the

screws will cause the impeller to move 0.05 mm

(0.002 in.) closer to the rear cover because of the

internal looseness in the bearing carrier threads.

This must be considered when setting the

impeller clearance. If possible, check results with

a feeler gauge.

f) If a cartridge seal [4200] is fitted it should be

reset at this point.

g) Check that the shaft can turn freely without

binding.

h) Ensure the coupling distance between shaft ends

(DBSE) is correct. Reset/re-align if necessary.

6.8 Disassembly

Refer to Safety section before dismantling the

pump.

Before dismantling the pump for

overhaul, ensure genuine Flowserve replacement

parts are available.

Refer to sectional drawings for part numbers and

identification. (See section 8, Parts lists and drawings.)

6.8.1

Bearing housing disassembly

To remove, proceed as follows:

a) Disconnect all auxiliary pipes and tubes where

applicable.

b) Remove coupling guard and disconnect coupling.

c) If oil lubricated frame, drain oil by removing drain

plug.

d) Record the gap between the bearing carrier

[3240] and bearing housing [3200] so that this

setting can be used during workshop assembly.

e) Place hoist sling through bearing housing adaptor

window.

f) Remove casing nuts [6582.1] and support foot

[3134] to baseplate screws.

g) Remove bearing housing assembly from pump

casing [1100].

h) The two threaded holes in the adaptor flange can

be used for jacking screws to assist with removal.

Summary of Contents for Durco Mark 3

Page 49: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 49 of 52 flowserve com Notes ...

Page 50: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 50 of 52 flowserve com Notes ...

Page 51: ...DURCO MARK 3 ISO FRAME MOUNTED ENGLISH 85392719 06 12 Page 51 of 52 flowserve com Notes ...